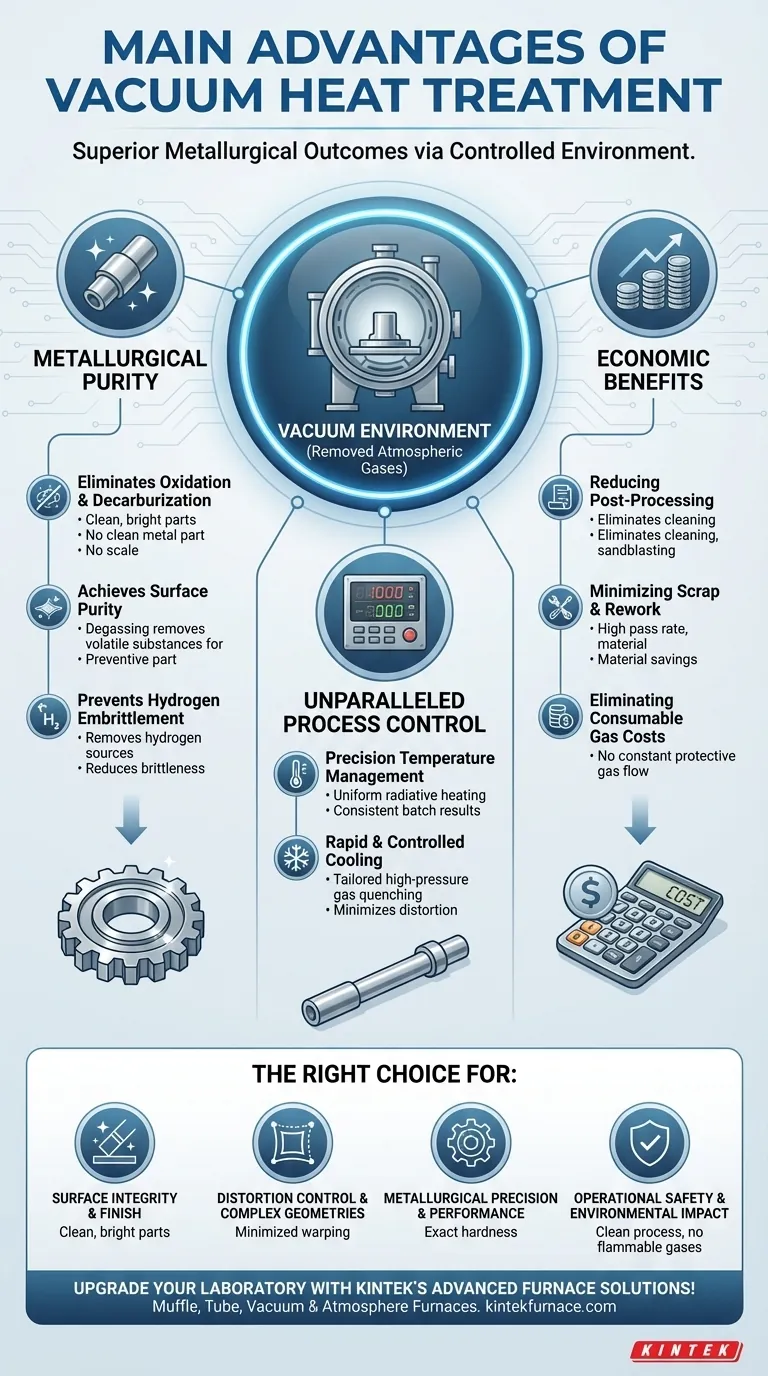

At its core, vacuum heat treatment provides superior metallurgical outcomes by fundamentally changing the treatment environment. By removing atmospheric gases, the process prevents surface reactions like oxidation and decarburization, resulting in cleaner parts with enhanced mechanical properties and exceptional dimensional stability.

The primary advantage of vacuum heat treatment is not just preventing negative effects, but enabling a level of process control that is impossible in a conventional atmosphere. This control over the environment, temperature, and cooling cycle is what delivers higher quality, consistency, and long-term cost efficiency.

The Core Principle: Why a Vacuum Changes Everything

Heat treatment relies on controlled thermal cycles to alter a material's properties. However, in a conventional furnace, the atmosphere itself—rich in oxygen, nitrogen, and water vapor—reacts with the hot metal surface, causing undesirable effects. A vacuum eliminates this variable.

Eliminating Oxidation and Decarburization

At elevated temperatures, oxygen aggressively bonds with most metals, forming a layer of oxide scale. This scale must be cleaned off in a costly secondary process and can compromise the part's surface finish.

Decarburization is the loss of carbon from the surface of steel, which softens the surface layer and reduces fatigue life. By removing the reactive gases, a vacuum environment completely prevents both oxidation and decarburization, producing clean, bright parts straight from the furnace.

Achieving Surface Purity

A vacuum doesn't just prevent contamination; it actively cleans the part. The low-pressure environment helps to pull volatile substances, oils, and trapped gases out of the material's surface, a process known as degassing.

This results in a metallurgically pure surface that is ideal for subsequent processes like brazing, welding, or coating.

Preventing Hydrogen Embrittlement

For certain high-strength alloys, exposure to hydrogen at high temperatures can cause embrittlement, a phenomenon where the material becomes brittle and prone to catastrophic failure.

Vacuum furnaces eliminate the sources of hydrogen (like dissociated water vapor) that are present in atmospheric furnaces, mitigating this risk.

Unparalleled Process Control and Consistency

Removing the atmosphere also has a profound impact on the physics of heating and cooling, giving engineers precise control over the entire thermal cycle.

Precision Temperature Management

In a vacuum, heat is transferred primarily through radiation, not convection. This allows for extremely uniform heating, even for parts with complex geometries.

Modern vacuum furnaces offer precise temperature control and repeatability, ensuring that every part in every batch receives the exact same thermal treatment. This level of consistency is critical for high-performance applications.

Rapid and Controlled Cooling

Cooling, or quenching, is just as critical as heating. Vacuum furnaces use high-pressure gas quenching, where an inert gas like nitrogen or argon is rapidly introduced to cool the parts.

The pressure and flow rate of this gas can be precisely controlled, allowing for tailored cooling curves that achieve the desired hardness while minimizing distortion and thermal stress. This is a significant advantage over the harsh and less controllable nature of oil or water quenching.

Understanding the Trade-offs and Considerations

While powerful, vacuum heat treatment is not the universal solution for every application. Objectivity requires acknowledging its specific context and limitations.

Initial Investment and Maintenance

Vacuum furnaces represent a significant capital investment compared to conventional atmospheric furnaces. The complexity of the system, including high-power vacuum pumps and seals, also demands specialized maintenance and skilled operators.

Batch Processing Nature

Most vacuum heat treatment is a batch process. While individual cycles can be fast, this may present a throughput limitation compared to the continuous belt furnaces used in some high-volume manufacturing environments.

The Impact on Your Bottom Line

The technical advantages of vacuum heat treatment translate directly into economic benefits, particularly when looking at the total cost of production.

Reducing Post-Processing Costs

Because parts emerge from the furnace clean and free of scale, you can often eliminate entire secondary operations like sandblasting, chemical cleaning, or grinding. This saves time, labor, and material handling costs.

Minimizing Scrap and Rework

The high degree of process control and repeatability dramatically increases the part pass rate. Reduced distortion and predictable metallurgical results mean less scrap and rework, leading to significant material and energy savings.

Eliminating Consumable Gas Costs

While vacuum furnaces use inert gas for quenching, they do not require a constant flow of expensive or flammable protective gases (like hydrogen or dissociated ammonia) throughout the heating cycle.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on your specific goals for the part and your manufacturing process.

- If your primary focus is surface integrity and finish: Vacuum treatment is unmatched for producing clean, bright parts that require no post-process cleaning.

- If your primary focus is distortion control and complex geometries: The uniform heating and controlled gas quenching of a vacuum furnace minimize the thermal stress that causes parts to warp.

- If your primary focus is metallurgical precision and performance: Vacuum treatment offers the highest level of control over the final hardness, case depth, and microstructure of the material.

- If your primary focus is operational safety and environmental impact: The process is inherently clean, free of pollutants, and eliminates the hazards associated with storing and handling flammable process gases.

By specifying vacuum heat treatment for applications where material integrity and process control are paramount, you are investing in a more predictable and higher-quality final product.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation & Decarburization | Eliminates surface reactions for clean, bright parts without secondary cleaning. |

| Achieves Surface Purity | Removes contaminants via degassing, ideal for welding or coating. |

| Prevents Hydrogen Embrittlement | Reduces brittleness risks in high-strength alloys. |

| Ensures Process Control | Uniform heating and controlled cooling minimize distortion and ensure consistency. |

| Reduces Costs | Lowers post-processing, scrap, and consumable gas expenses. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your needs. Our deep customization capabilities ensure precise performance for applications requiring superior surface integrity, distortion control, and metallurgical precision. Contact us today to discuss how our solutions can enhance your heat treatment processes and boost efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance