Choosing the right vacuum pump for a furnace is not a single decision, but a careful balancing act. The selection hinges on two primary technical criteria: the ultimate vacuum level the pump can achieve and its pumping speed. These factors directly determine the purity of your process environment, the speed of your operational cycles, and the system's ability to handle gas loads during heating.

The core challenge is not simply to achieve the lowest possible pressure. It is to select a vacuum system that cost-effectively matches the specific purity and throughput demands of your materials and process, ensuring both product quality and operational efficiency.

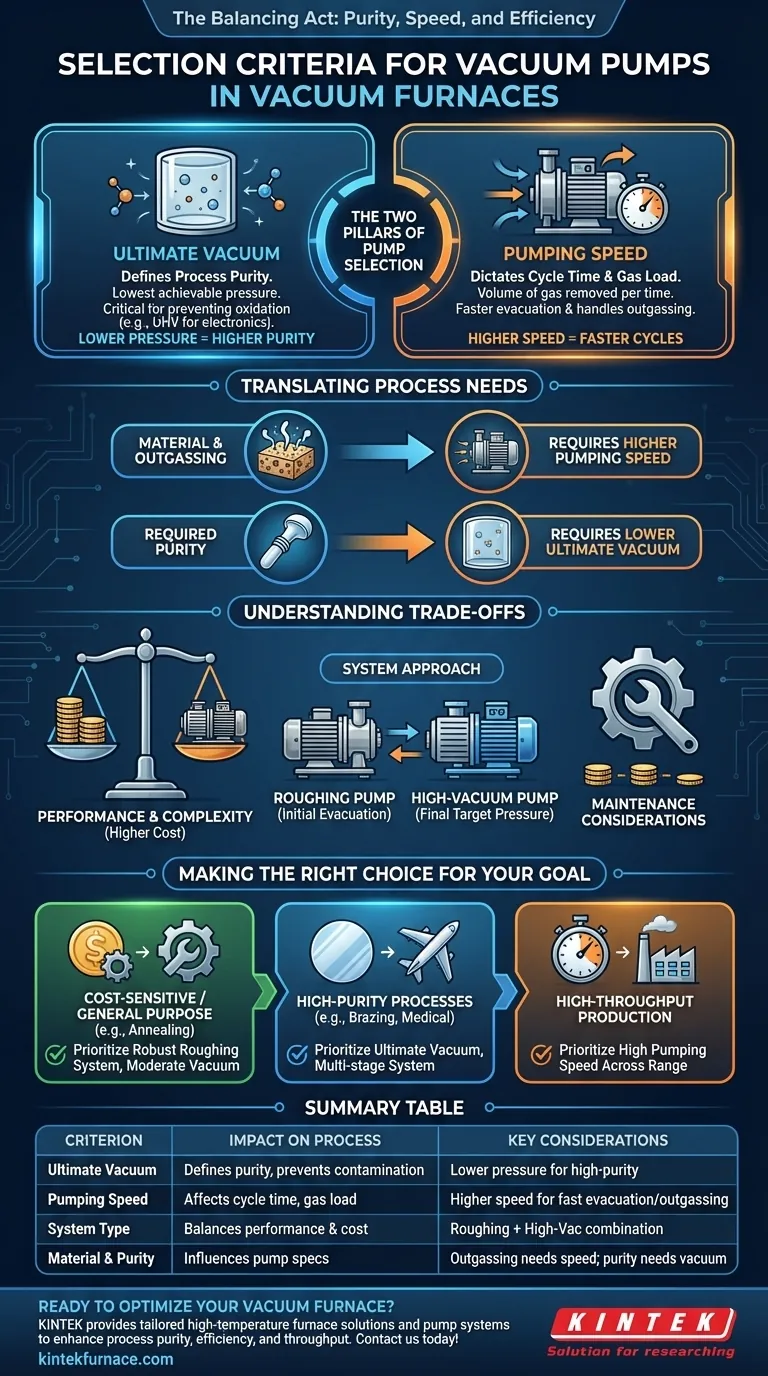

The Two Pillars of Pump Selection

Understanding the two fundamental performance metrics of any vacuum pump is the first step. These criteria form the technical foundation for your entire furnace system.

Ultimate Vacuum: Defining Process Purity

The ultimate vacuum is the lowest pressure a pump can achieve in a sealed, clean, and empty system. This metric is a direct indicator of how "empty" the chamber can get.

A lower ultimate vacuum means fewer gas molecules remain, which is critical for preventing unwanted chemical reactions like oxidation. This ensures the highest level of process purity.

Vacuum levels are often categorized by application, from low vacuum for simple heat treatments to ultra-high vacuum (UHV) for sensitive electronics or medical-grade manufacturing, which may require pressures as low as 1x10⁻¹¹ Torr.

Pumping Speed: Dictating Cycle Time and Gas Load

Pumping speed measures the volume of gas a pump can remove from the chamber per unit of time (e.g., in liters per second). This directly impacts two key operational factors.

First, it determines the evacuation time, or how quickly the furnace can reach its target vacuum level. Faster pump-down means shorter cycle times and higher throughput.

Second, it dictates how well the system can handle outgassing—the release of trapped gases from the workpiece and chamber walls as they are heated. A pump with sufficient speed can maintain a stable vacuum level even when managing this continuous gas load.

Translating Process Needs into Pump Specifications

Your specific application is what gives context to the technical numbers. The material, desired purity, and process steps all influence the final pump choice.

Material Requirements and Outgassing

The materials you process are a major source of gas. Porous materials, components with surface contaminants, or binders used in processes like sintering release significant gas volumes when heated.

Furnaces handling high-outgassing materials require pumps with higher pumping speeds to manage this gas load and prevent the chamber pressure from rising above its target.

Required Purity and Contamination

The required purity of the final product is paramount. Processes like vacuum brazing, medical implant manufacturing, or semiconductor fabrication demand a high-purity environment to prevent surface oxidation and ensure strong, clean bonds.

For these critical applications, the ultimate vacuum level of the pump system is the most important criterion. A lower base pressure minimizes the risk of product contamination.

Understanding the Trade-offs

Selecting a vacuum pump is an exercise in balancing performance, cost, and complexity. There is no single "best" pump, only the best pump for a specific job.

Performance vs. Cost

There is a direct correlation between vacuum performance and cost. A simple, low-vacuum system suitable for basic annealing is far more cost-effective than a multi-stage, high-vacuum furnace for aerospace components.

High-vacuum and ultra-high-vacuum systems deliver unmatched precision and purity but come with a significantly higher initial investment.

Roughing Pumps vs. High-Vacuum Pumps

No single pump can efficiently operate from atmospheric pressure down to a high vacuum. Therefore, vacuum furnaces almost always use a system of pumps.

A roughing pump (like a rotary vane or scroll pump) does the initial work of evacuating the chamber to a low-vacuum level. Then, a high-vacuum pump (like a turbomolecular or diffusion pump) takes over to achieve the final target pressure. Your selection must account for the entire system, not just one component.

Maintenance and Operational Complexity

Higher-performance pumps often require more sophisticated maintenance and infrastructure. Turbomolecular pumps, for example, are precision high-speed devices that are sensitive to vibration and contamination.

This complexity contributes to the total cost of ownership beyond the initial purchase price, a factor that must be included in your decision.

Making the Right Choice for Your Goal

To select the ideal pump system, begin by defining your most critical process outcome.

- If your primary focus is cost-sensitive, general-purpose applications (e.g., annealing, tempering): Prioritize a robust, simpler roughing pump system with a moderate vacuum level and sufficient speed for reasonable cycle times.

- If your primary focus is high-purity processes (e.g., brazing, medical implants, aerospace): Prioritize the ultimate vacuum level of a multi-stage system to ensure product quality, even at a higher cost.

- If your primary focus is high-throughput production: Prioritize high pumping speed across the entire pressure range to minimize pump-down times and effectively manage outgassing.

By aligning your pump selection with your specific process requirements, you ensure both operational efficiency and final product integrity.

Summary Table:

| Criterion | Impact on Process | Key Considerations |

|---|---|---|

| Ultimate Vacuum | Defines process purity and prevents contamination | Lower pressure for high-purity applications like brazing or medical implants |

| Pumping Speed | Affects cycle time and gas load management | Higher speed for faster evacuation and handling outgassing from materials |

| System Type | Balances performance and cost | Roughing pumps for initial evacuation, high-vacuum pumps for final pressure |

| Material & Purity | Influences pump specifications | High-outgassing materials need faster pumps; purity demands dictate vacuum levels |

Ready to optimize your vacuum furnace with the right pump? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored vacuum pump systems can enhance your process purity, efficiency, and throughput!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits