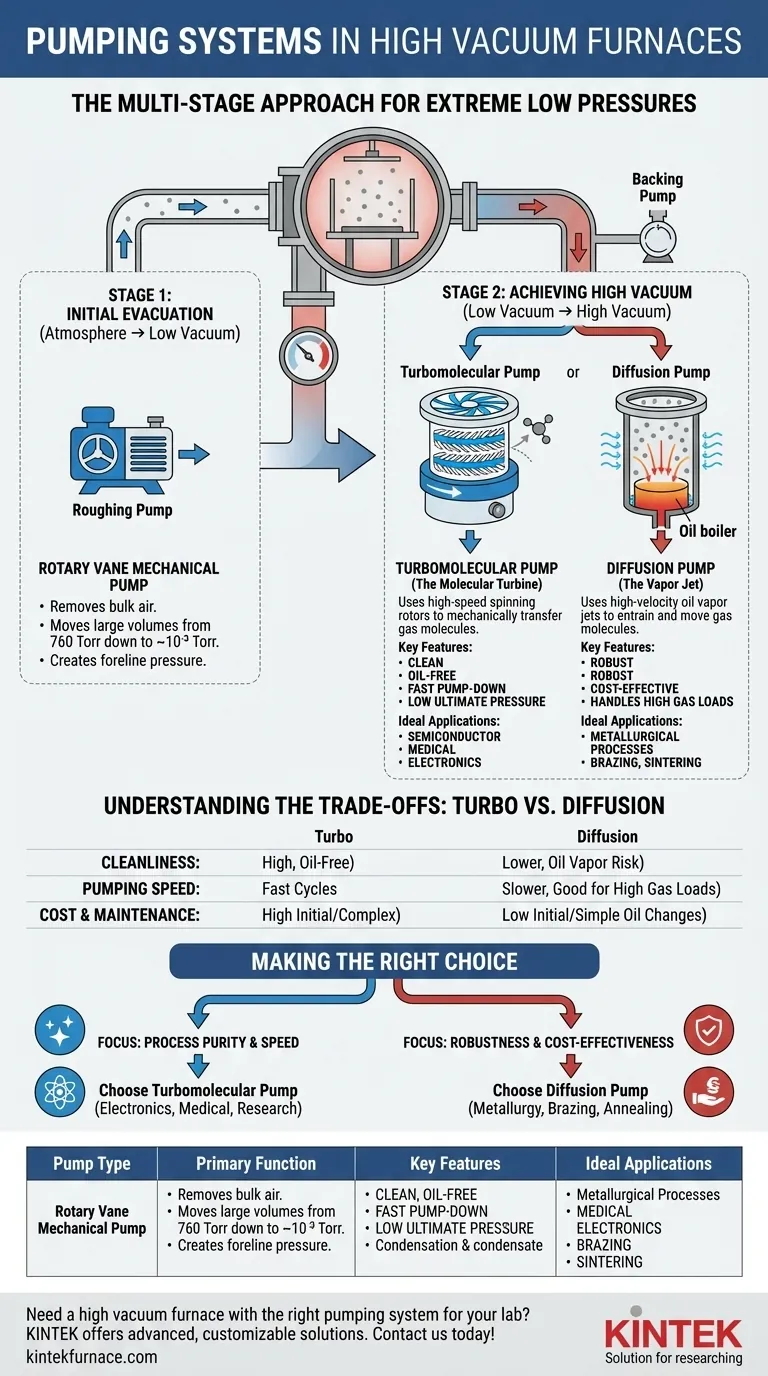

At its core, a high vacuum furnace relies on a multi-stage pumping system. These systems always combine a mechanical "roughing" pump, which performs the initial evacuation, with a specialized high-vacuum pump—most commonly a turbomolecular pump or a diffusion pump—to achieve the extremely low pressures required for high-purity thermal processing.

No single pump can efficiently bridge the vast pressure gap between the atmosphere and a high vacuum. The solution is a strategic pairing: a high-volume mechanical pump creates the initial low-pressure environment, enabling a high-vacuum pump to take over and achieve the final target pressure.

Why a Multi-Stage System is Essential

Achieving a high vacuum is a process of removing gas molecules from a sealed chamber. Different pumps are designed to operate efficiently at different pressure ranges, making a single-pump solution impractical.

The Role of the Mechanical "Roughing" Pump

The first stage of evacuation is handled by a mechanical pump, often a rotary vane pump. Its job is to remove the bulk of the air from the furnace chamber, reducing the pressure from atmospheric levels (760 Torr) down to the low vacuum range (around 10⁻³ Torr).

These pumps are excellent at moving large volumes of gas but become highly inefficient at lower pressures. They do the initial "heavy lifting" to create an environment where the high-vacuum pump can begin to operate.

The Role of the High-Vacuum "Finisher" Pump

Once the mechanical pump has established a sufficient "foreline" or "backing" pressure, the high-vacuum pump takes over. These pumps work on principles of momentum transfer, effectively capturing individual gas molecules and directing them toward the mechanical pump for final expulsion from the system.

The Core High-Vacuum Pump Technologies

The choice of high-vacuum pump is a defining feature of the furnace's capability. The two most common options are turbomolecular and diffusion pumps.

Turbomolecular Pumps (The Molecular Turbine)

A turbomolecular pump, or "turbo pump," operates like a multi-stage turbine. It uses sets of rotor and stator blades spinning at extremely high speeds (tens of thousands of RPM) to literally "bat" gas molecules from the furnace chamber toward the backing pump outlet.

This is a purely mechanical, momentum-transfer process. Because it introduces no vapors into the system, it is considered a "clean" pumping method.

Diffusion Pumps (The Vapor Jet)

A diffusion pump is a simpler device with no moving parts. It works by boiling a specialized oil at the bottom of the pump stack. This creates a high-velocity jet of oil vapor that travels downward, entraining gas molecules from the furnace chamber and dragging them toward the foreline outlet.

Cooling coils on the pump's outer wall cause the oil vapor to condense and return to the boiler, while the captured gas is removed by the backing pump.

Understanding the Trade-offs: Turbo vs. Diffusion

Choosing between a turbomolecular and a diffusion pump involves balancing performance, cleanliness, and operational complexity.

Cleanliness and Contamination

Turbomolecular pumps provide an inherently cleaner, hydrocarbon-free vacuum because they use no vaporized fluids. This is critical for highly sensitive applications like semiconductor manufacturing, medical device fabrication, and electronics where any oil contamination could ruin the product.

Diffusion pumps, by their nature, use oil vapor. While modern designs include baffles to minimize it, the risk of oil backstreaming into the furnace chamber always exists, which can be detrimental to certain processes.

Pumping Speed and Performance

Turbo pumps generally offer faster pump-down cycles and can reach lower ultimate pressures than diffusion pumps. They are ready to operate almost immediately after reaching their rotational speed.

Diffusion pumps require a warm-up period for the oil to boil and a cool-down period afterward. However, they are often more effective at handling large, sudden bursts of gas (high gas loads) that can occur during process outgassing.

Cost and Maintenance

Diffusion pumps are mechanically simple, robust, and typically have a lower initial purchase cost. Their main maintenance involves periodic oil changes.

Turbomolecular pumps are more complex precision instruments with higher initial costs. Their high-speed bearings have a finite lifespan and will eventually require a costly rebuild or replacement.

Making the Right Choice for Your Goal

The pumping system must be matched to the demands of the process materials and the desired end product.

- If your primary focus is process purity and speed: A turbomolecular pump system is the superior choice for its clean, oil-free operation and rapid cycling, ideal for electronics, medical, and research applications.

- If your primary focus is robustness and cost-effectiveness: A well-maintained diffusion pump system is a reliable workhorse for metallurgical processes like brazing, sintering, and annealing where extreme purity is less critical.

Ultimately, selecting the correct pumping system is a calculated decision based on the specific balance of purity, speed, and budget your application demands.

Summary Table:

| Pump Type | Primary Function | Key Features | Ideal Applications |

|---|---|---|---|

| Mechanical (Roughing) Pump | Initial evacuation from atmosphere to low vacuum (~10⁻³ Torr) | High gas volume handling, creates backing pressure | General roughing stage for all systems |

| Turbomolecular Pump | Achieves high vacuum with clean, oil-free operation | Fast pump-down, low ultimate pressure, hydrocarbon-free | Semiconductor, medical devices, electronics |

| Diffusion Pump | Achieves high vacuum using oil vapor jets | Robust, cost-effective, handles high gas loads | Brazing, sintering, annealing where purity is less critical |

Need a high vacuum furnace with the right pumping system for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization capabilities to meet your unique experimental requirements. Contact us today via our contact form to discuss how we can enhance your thermal processing efficiency and purity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion