In short, a hot wall vacuum furnace is a design where the workpieces are placed inside a sealed chamber, known as a retort, which is then evacuated to create a vacuum. The heating elements are located outside of this retort. Heat is transferred through the retort's walls to the material inside, meaning the inner chamber wall itself becomes hot.

The defining characteristic of a hot wall furnace is the physical separation of the heating elements from the vacuum environment. This simple, robust design protects the heaters from the process atmosphere and the workpieces from potential contamination from the heaters.

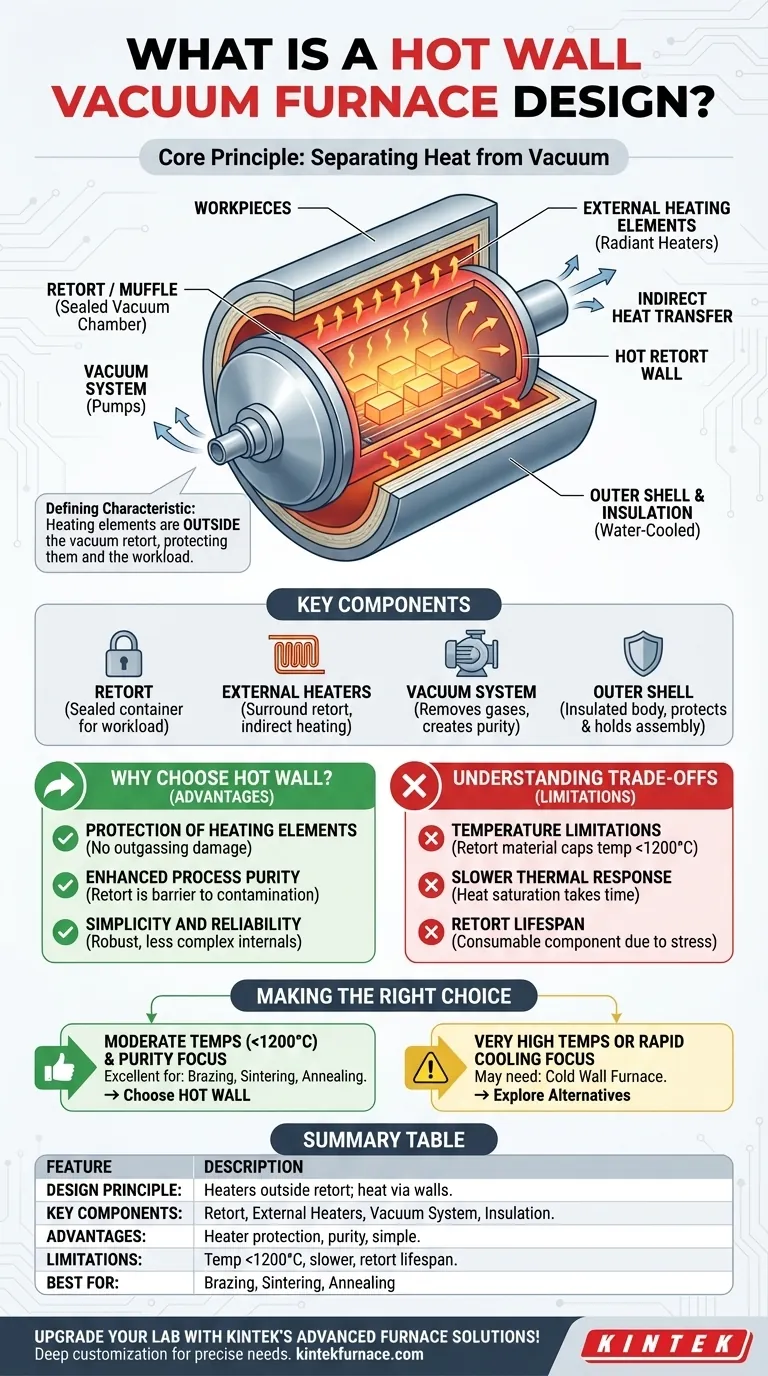

The Core Principle: Separating Heat from Vacuum

The "hot wall" name is descriptive. Because the heaters are outside the vacuum chamber, the chamber walls must get hot to transfer thermal energy to the parts within. This design is built on a few key components working in concert.

The Retort (or Muffle)

The retort is the heart of the system. It is a sealed container, often cylindrical or box-shaped, that holds the workload and contains the vacuum or specialized process atmosphere. It must be made from a material that can withstand high temperatures while under vacuum pressure.

External Heating Elements

The heating elements surround the outside of the retort. They heat the retort wall via radiation and convection. The hot retort wall then radiates that heat inward to the parts being processed, providing indirect but uniform heating.

The Vacuum System

Pumps are connected directly to the retort to remove air and other gases, creating a controlled, oxygen-free environment. This prevents oxidation and other unwanted chemical reactions on the surface of the workpieces during the high-temperature cycle.

The Outer Shell and Insulation

The entire assembly—retort and heating elements—is housed within a larger, insulated furnace body. This outer shell is typically made of steel and is often water-cooled to protect it from the high internal temperatures and maintain structural integrity.

Why Choose a Hot Wall Design?

The architecture of a hot wall furnace provides several distinct operational advantages that make it suitable for a wide range of thermal processes.

Protection of Heating Elements

Because the heating elements operate in ambient air rather than in a vacuum, there is no risk of them being damaged by outgassing from the workpieces. This simplifies heater design and can significantly extend their operational lifespan.

Enhanced Process Purity

The retort acts as an impermeable barrier. It prevents any particles from the furnace insulation or the heating elements themselves from contaminating the workload, ensuring a clean processing environment.

Simplicity and Reliability

The design is mechanically straightforward and robust. With fewer complex components inside the vacuum chamber, maintenance is often simpler and the system is highly reliable for consistent, repeatable industrial processes like brazing and annealing.

Understanding the Trade-offs

No design is universally superior. The hot wall approach has inherent limitations that are critical to understand when selecting a furnace.

Temperature Limitations

The maximum operating temperature of a hot wall furnace is limited by the material strength of the retort itself. The retort must remain stable and sealed under both high heat and the pressure differential of the vacuum, which often caps its use at lower temperatures than alternative designs.

Slower Thermal Response

Because heat must first saturate the retort wall before reaching the parts, both heating and cooling cycles can be slower. This can lead to longer overall process times compared to "cold wall" designs where heaters are inside the chamber.

Retort Lifespan

The retort is subjected to extreme thermal cycling under pressure. This stress makes it a consumable component that will eventually require replacement, representing a recurring operational cost.

Making the Right Choice for Your Application

Selecting the correct furnace design comes down to matching its capabilities with your specific process requirements and materials.

- If your primary focus is process purity and reliability for brazing, sintering, or annealing at moderate temperatures (typically below 1200°C): The robust and clean environment of a hot wall furnace is an excellent and cost-effective choice.

- If your primary focus is reaching very high temperatures or achieving rapid cooling (quenching): The limitations of the retort material and indirect heating may necessitate exploring a cold wall furnace design.

Understanding this fundamental design distinction allows you to select the precise furnace technology that aligns with your material, process, and operational goals.

Summary Table:

| Feature | Description |

|---|---|

| Design Principle | Heating elements outside retort; heat transfers through walls |

| Key Components | Retort, external heating elements, vacuum system, insulation |

| Advantages | Protects heaters, ensures process purity, simple and reliable |

| Limitations | Temperature limits (<1200°C), slower thermal response, retort lifespan |

| Best For | Brazing, sintering, annealing at moderate temperatures |

Upgrade your lab's thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing