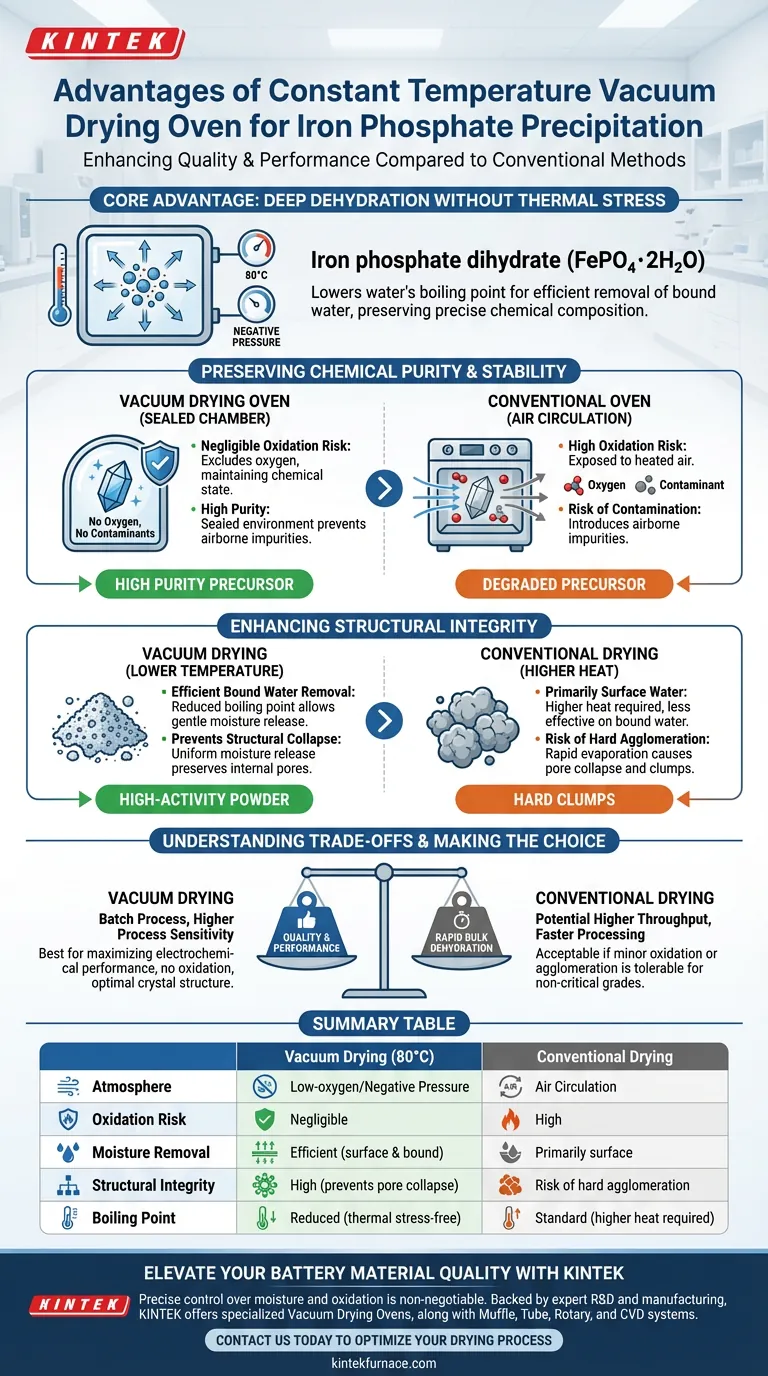

The use of a constant temperature vacuum drying oven specifically at 80 °C significantly enhances the quality of iron phosphate precipitation compared to conventional methods. This approach accelerates the removal of both adsorbed and chemically bound water while maintaining a low-oxygen environment. By eliminating the risk of oxidation and impurity introduction, this method preserves the structural stability of the iron phosphate dihydrate (FePO4·2H2O) precursor, which is critical for downstream battery performance.

The core advantage of vacuum drying lies in altering the physics of evaporation: by lowering the boiling point of water, you can achieve deep dehydration without the thermal stress that damages crystal structures. This ensures the precursor retains the precise chemical composition required for high-quality material synthesis.

Preserving Chemical Purity and Stability

The primary challenge in drying iron phosphate is removing moisture without altering the material's chemical state. Vacuum drying addresses this through precise environmental control.

Prevention of Oxidation

Conventional ovens rely on heated air circulation, which exposes the material to oxygen. For iron-based materials, this presents a significant risk of unwanted oxidation.

A vacuum oven creates a negative pressure environment that effectively excludes oxygen. This ensures the iron phosphate remains in its intended chemical state throughout the drying process.

Elimination of Contamination

Standard drying methods can introduce airborne impurities or dust. Vacuum drying occurs in a sealed chamber, preventing the introduction of external contaminants.

This isolation is vital for maintaining the high purity levels required for battery-grade precursors, where even trace impurities can degrade performance.

Enhancing Structural Integrity

Beyond chemical purity, the physical structure of the dried precipitate dictates how well it will perform in subsequent synthesis steps.

Efficient Removal of Bound Water

Iron phosphate precursors contain both surface water and "bound" water integrated into the structure.

At 80 °C under vacuum, the boiling point of water is significantly reduced. This allows for the efficient removal of stubborn bound water without resorting to extreme temperatures that could degrade the material.

Preventing Structural Collapse

Rapid evaporation at high temperatures in conventional ovens can cause surface tension issues, leading to pore collapse or hard agglomeration.

Vacuum drying promotes a more uniform release of moisture from within the material. This preserves the internal porous structure and ensures the precursor remains a loose, high-activity powder rather than forming hard clumps.

Understanding the Trade-offs

While vacuum drying offers superior material quality, it is important to recognize the operational differences compared to conventional methods.

Throughput Limitations

Vacuum drying is typically a batch process, which may offer lower throughput compared to continuous belt dryers used in conventional heating.

Process Sensitivity

The vacuum environment must be carefully controlled. Applying a vacuum too rapidly can cause "bumping," where solvents boil violently and physically displace the powder within the chamber.

Making the Right Choice for Your Goal

Selecting the correct drying method depends on the strictness of your material requirements.

- If your primary focus is maximizing electrochemical performance: Prioritize vacuum drying to ensure the iron phosphate precursor remains free of oxidation and retains its optimal crystal structure.

- If your primary focus is rapid bulk dehydration of non-critical grades: Conventional drying methods may offer faster processing times, provided that minor oxidation or agglomeration is acceptable.

By controlling the drying atmosphere and temperature, you transform drying from a simple dehydration step into a critical quality assurance process for your final material.

Summary Table:

| Feature | Vacuum Drying (80°C) | Conventional Drying |

|---|---|---|

| Atmosphere | Low-oxygen/Negative Pressure | Air Circulation |

| Oxidation Risk | Negligible | High |

| Moisture Removal | Efficient (surface & bound) | Primarily surface |

| Structural Integrity | High (prevents pore collapse) | Risk of hard agglomeration |

| Purity Level | High (sealed environment) | Risk of airborne contaminants |

| Boiling Point | Reduced (thermal stress-free) | Standard (higher heat required) |

Elevate Your Battery Material Quality with KINTEK

Precise control over moisture and oxidation is non-negotiable for high-performance iron phosphate synthesis. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Drying Ovens, along with Muffle, Tube, Rotary, and CVD systems—all customizable to meet your laboratory's unique high-temperature requirements.

Ensure the structural stability and chemical purity of your precursors with our advanced thermal solutions. Contact us today to optimize your drying process and see how our expertise can drive your material innovation forward.

Visual Guide

References

- Ziyang Xu, Jingkui Qu. Sustainable Utilization of Fe(Ⅲ) Isolated from Laterite Hydrochloric Acid Lixivium via Ultrasonic-Assisted Precipitation to Synthesize LiFePO4/C for Batteries. DOI: 10.3390/ma17020342

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What technical requirements must a furnace meet for Inconel 718 hardening? Master Precision Aging & Cooling

- What is the purpose of using screening equipment to pretreat magnesium slag before its recovery via vacuum distillation? Optimize Your Recovery Process

- What is the function of a laboratory vacuum drying oven for lignin-based precursors? Ensure Structural Integrity

- How is a vacuum furnace energy-efficient? Uncover Key Mechanisms for Lower Costs

- What processes are hot wall vacuum furnaces used for? Ideal for precise, uniform low-temperature heat treatments

- Why is graphite commonly used as a heating element in vacuum furnaces? Unlock High-Temp Stability & Efficiency

- What are the steps in the discharge plasma sintering process? Master Fast, High-Density Material Consolidation

- Why is a high-precision vacuum sealing system necessary for CrSb? Ensure Pure Crystal Growth & Prevent Oxidation