A laboratory vacuum drying oven serves a critical protective function in treating lignin-based precursors by creating a low-pressure environment that allows for deep dehydration at moderate temperatures (typically around 80°C). By lowering the boiling point of water and solvents, the oven removes moisture from within porous structures without exposing the sensitive lignin material to the oxidative degradation or thermal shock associated with standard high-temperature drying.

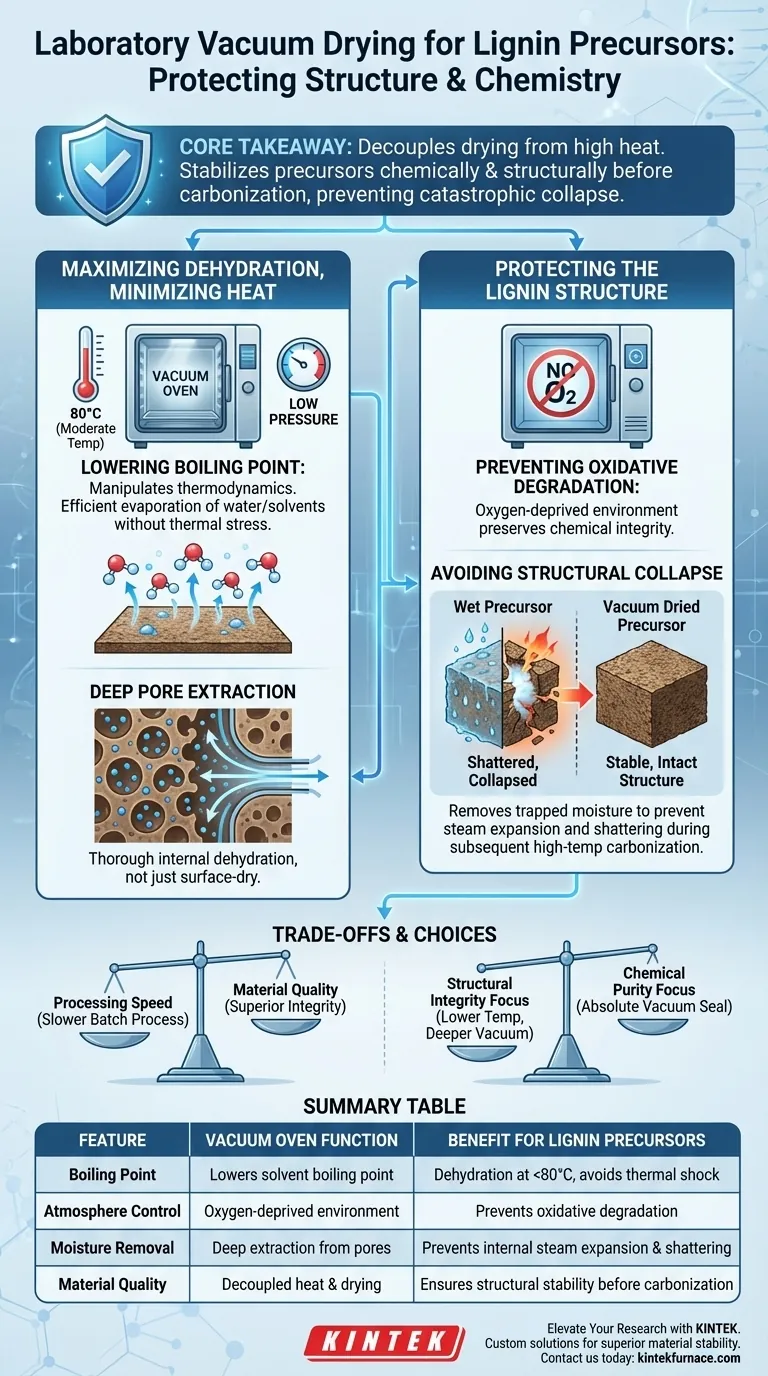

Core Takeaway The vacuum drying oven acts as a stabilization stage, decoupling the drying process from high heat. It ensures the precursor is chemically stable and structurally sound before carbonization, preventing the catastrophic structural collapse that occurs when residual internal moisture rapidly expands at high temperatures.

Maximizing Dehydration While Minimizing Heat

Lowering the Boiling Point

The fundamental advantage of this equipment is its ability to manipulate thermodynamics. By reducing the chamber pressure, the oven significantly lowers the boiling point of water and volatile solvents.

This allows the precursors to be dried thoroughly at temperatures as low as 80°C. You achieve efficient evaporation without subjecting the material to thermal stress that could alter its fundamental properties.

Deep Pore Extraction

Lignin-based precursors often possess complex, porous architectures. Standard drying methods frequently fail to remove moisture trapped deep within these pores.

The vacuum environment effectively pulls residual moisture and organic solvents from the core of the material. This ensures that the precursor is not just surface-dry, but thoroughly dehydrated internally.

Protecting the Lignin Structure

Preventing Oxidative Degradation

Lignin is highly susceptible to chemical changes when exposed to oxygen at elevated temperatures. A standard air oven can inadvertently trigger oxidation, altering the chemical composition of the precursor before the main reaction takes place.

A vacuum oven operates in an oxygen-deprived environment. This prevents unnecessary oxidative degradation, ensuring the chemical integrity of the lignin is preserved for the subsequent synthesis or carbonization steps.

Avoiding Structural Collapse

The most critical role of this drying phase is preparing the material for high-temperature carbonization. If moisture remains trapped inside the pores, the rapid heating during carbonization will cause that water to flash into steam.

This sudden expansion can shatter the material's internal structure. By removing this moisture beforehand, the vacuum oven prevents structural collapse, maintaining the precursor's intended morphology and porosity.

Understanding the Trade-offs

Processing Speed vs. Material Quality

While superior for quality, vacuum drying is generally slower than forced-air convection drying. It is a batch process that prioritizes structural integrity over throughput speed.

Equipment Sensitivity

Vacuum drying requires precise control over pressure seals and pump maintenance. Unlike simple heating ovens, inconsistent pressure levels can lead to uneven drying or incomplete solvent removal, potentially compromising the batch.

Making the Right Choice for Your Goal

To maximize the utility of a vacuum drying oven for lignin precursors, align your settings with your specific objectives:

- If your primary focus is Structural Integrity: Prioritize a lower temperature setting with a deeper vacuum to gently extract moisture without collapsing fine pores.

- If your primary focus is Chemical Purity: Ensure the vacuum seal is absolute to eliminate all oxygen exposure, preventing any pre-carbonization oxidation.

The vacuum drying oven is not merely a drying tool; it is a prerequisite for high-performance carbon materials, ensuring that the precursor entering your furnace is pure, stable, and dry.

Summary Table:

| Feature | Vacuum Drying Oven Function | Benefit for Lignin Precursors |

|---|---|---|

| Boiling Point | Lowers boiling point of solvents | Dehydration at <80°C to avoid thermal shock |

| Atmosphere Control | Oxygen-deprived environment | Prevents oxidative degradation of chemical bonds |

| Moisture Removal | Deep extraction from porous cores | Prevents internal steam expansion and shattering |

| Material Quality | Decoupled heat and drying stages | Ensures structural stability before carbonization |

Elevate Your Precursor Research with KINTEK

Don't let moisture compromise your high-performance carbon materials. KINTEK provides expert-engineered laboratory solutions designed to preserve the chemical and structural integrity of your sensitive precursors.

Backed by industry-leading R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are drying lignin-based materials or conducting high-temperature synthesis, our lab furnaces are fully customizable to meet your unique research needs.

Ready to achieve superior material stability? Contact us today to find your custom solution.

Visual Guide

References

- Yuebin Xi, Binpeng Zhang. Production of Lignin-Derived Functional Material for Efficient Electromagnetic Wave Absorption with an Ultralow Filler Ratio. DOI: 10.3390/polym16020201

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the significance of vacuum sintering in metal processing, and how do continuous vacuum furnaces facilitate it? Unlock High-Purity Metal Parts

- What options are available for the vacuum furnace system? Customize for Precision and Performance

- How does a vacuum furnace work? Achieve Pure, Contamination-Free Thermal Processing

- What are the main components of a vacuum furnace's internal structure? Optimize Your Heat Treatment Process

- Why is a de-oiling pre-treatment step required in magnesium sublimation? To Ensure High-Purity Recovery

- What is the role of the 50 MPa external pressure applied during SPS for Ti64? Optimize Density and Grain Size

- What are the primary functions of a vacuum annealing furnace for Ti10Mo8Nb alloys? Achieve Purity & Beta-Phase Stability

- How does vacuum brazing differ from welding? Precision Joining Without Melting Base Materials