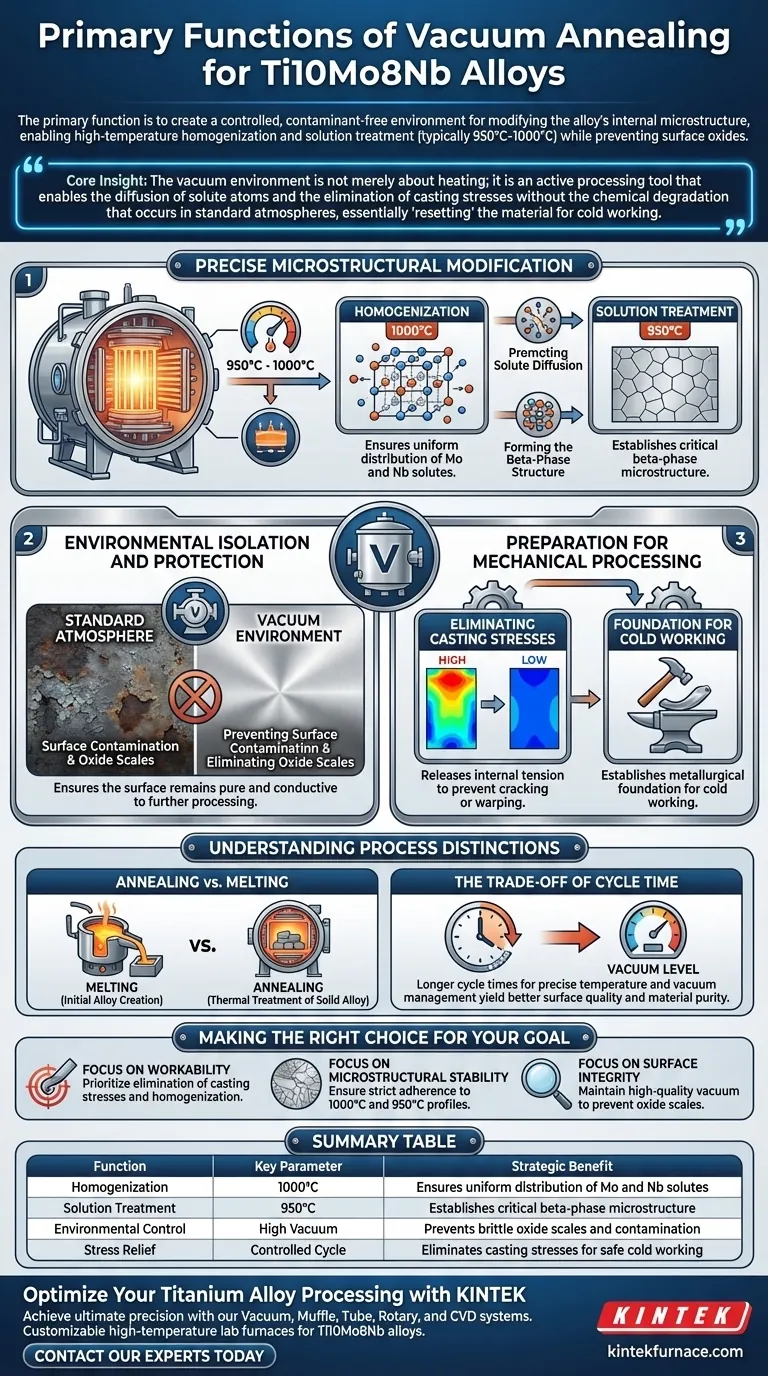

The primary function of a vacuum annealing furnace in the treatment of Ti10Mo8Nb alloys is to create a controlled, contaminant-free environment for modifying the alloy's internal microstructure. Specifically, it allows for high-temperature homogenization and solution treatment—typically between 950°C and 1000°C—while strictly preventing the formation of surface oxides.

Core Insight: The vacuum environment is not merely about heating; it is an active processing tool that enables the diffusion of solute atoms and the elimination of casting stresses without the chemical degradation that occurs in standard atmospheres, essentially "resetting" the material for cold working.

Precise Microstructural Modification

Homogenization and Solution Treatment

The furnace maintains precise high-temperature plateaus, such as 1000°C for homogenization and 950°C for solution treatment.

These specific thermal profiles are critical for dissolving alloying elements uniformly throughout the titanium matrix.

Promoting Solute Diffusion

The controlled heat input accelerates the diffusion of solute atoms (Molybdenum and Niobium) within the alloy.

This atomic movement is necessary to stabilize the internal chemistry before the material cools.

Forming the Beta-Phase Structure

The ultimate goal of this thermal cycle is to establish a specific beta-phase microstructure.

This phase provides the necessary material characteristics required for the final application of the Ti10Mo8Nb alloy.

Environmental Isolation and Protection

Preventing Surface Contamination

Titanium alloys are highly reactive to oxygen and nitrogen at high temperatures.

The vacuum furnace creates an inert environment that modifies the alloy without introducing surface contamination.

Eliminating Oxide Scales

In a standard furnace, heat treatment would result in a hard, brittle oxide shell (scale).

Vacuum annealing eliminates the formation of these oxide scales, ensuring the surface remains pure and conductive to further processing.

Preparation for Mechanical Processing

Eliminating Casting Stresses

The annealing process effectively releases internal tension known as casting stresses.

Removing these residual stresses is vital to prevent cracking or warping during subsequent manufacturing steps.

Foundation for Cold Working

By softening the matrix and homogenizing the structure, the furnace establishes the metallurgical foundation for cold working.

This ensures the alloy is ductile enough to be shaped mechanically without failing.

Understanding Process Distinctions

Annealing vs. Melting

It is crucial to distinguish this process from the initial alloy creation.

While a vacuum non-consumable arc furnace is used to melt raw materials (Titanium, Molybdenum, Niobium) to ensure chemical composition, the vacuum annealing furnace is used strictly for thermal treatment of the solid alloy to adjust its properties.

The Trade-off of Cycle Time

Vacuum annealing typically offers a more even heat distribution and better surface quality, but it requires rigorous cycle management.

Achieving the necessary vacuum levels and precise temperature ramp-ups often requires longer cycle times compared to atmospheric treatments, a necessary trade-off for material purity.

Making the Right Choice for Your Goal

To maximize the efficacy of your heat treatment process, align your furnace parameters with your specific metallurgical objectives:

- If your primary focus is Workability: Prioritize the elimination of casting stresses and homogenization to ensure the material can withstand subsequent cold working without fracture.

- If your primary focus is Microstructural Stability: Ensure strict adherence to the 1000°C and 950°C temperature profiles to guarantee the proper diffusion of solute atoms and the formation of the beta-phase.

- If your primary focus is Surface Integrity: Maintain a high-quality vacuum to preventing oxide scales, eliminating the need for aggressive post-treatment surface cleaning.

The vacuum annealing furnace is the gatekeeper that transforms a cast Ti10Mo8Nb ingot into a workable, high-performance engineering material.

Summary Table:

| Function | Key Parameter | Strategic Benefit |

|---|---|---|

| Homogenization | 1000°C | Ensures uniform distribution of Mo and Nb solutes |

| Solution Treatment | 950°C | Establishes critical beta-phase microstructure |

| Environmental Control | High Vacuum | Prevents brittle oxide scales and contamination |

| Stress Relief | Controlled Cycle | Eliminates casting stresses for safe cold working |

Optimize Your Titanium Alloy Processing with KINTEK

Achieve the ultimate precision in your metallurgical workflows. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, Tube, Rotary, and CVD systems. Our high-temperature lab furnaces are fully customizable to meet the specific homogenization and solution treatment needs of Ti10Mo8Nb alloys and other advanced materials.

Don't settle for surface contamination or inconsistent phases. Contact our experts today to find the perfect customizable furnace for your unique research and production requirements!

Visual Guide

References

- Edwin Gilberto Medina Bejarano, Daniela Sachs. Evaluation of corrosion resistance and biocompatibility test of Ti10Mo8Nb alloy for biomedical applications. DOI: 10.33448/rsd-v14i5.48744

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why is a double-chamber device preferred over a standard electric furnace for sintering? Achieve Oxidation-Free Results

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?