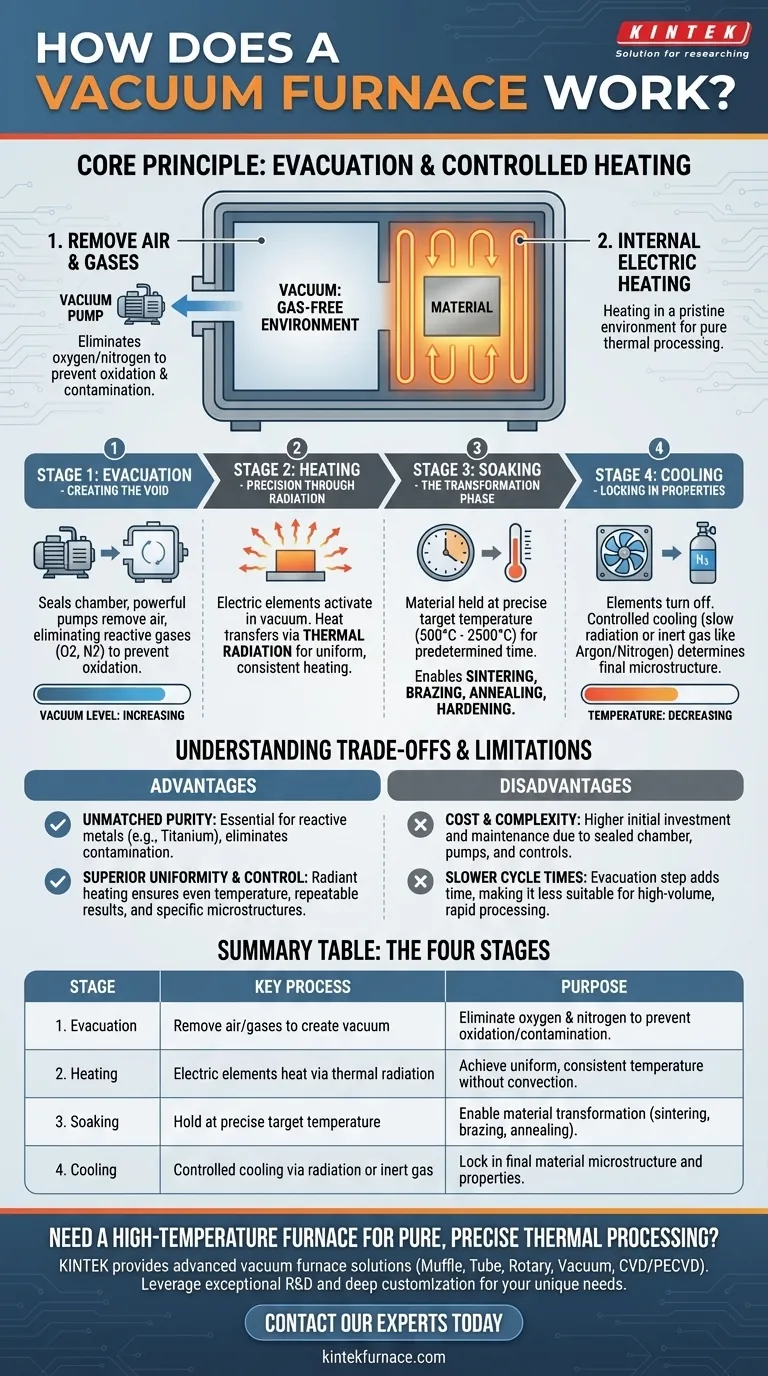

At its core, a vacuum furnace works by first removing the air and other gases from a sealed chamber to create a vacuum. It then uses internal electric heating elements to heat the material inside. This two-step process—evacuation followed by controlled heating—is the key, as it prevents the oxidation and contamination that would occur if the material were heated in the presence of air.

A standard furnace heats materials in an atmosphere, inevitably causing surface reactions like oxidation. A vacuum furnace solves this fundamental problem by first creating a pristine, gas-free environment, which enables exceptionally pure and precise thermal processing at extreme temperatures.

The Four-Stage Process of Vacuum Heating

The operation of a vacuum furnace isn't just about heating; it's a carefully choreographed sequence designed to control a material's environment and properties from start to finish.

Stage 1: Evacuation - Creating the Void

The process begins by sealing the material inside the furnace chamber. A powerful vacuum system, typically involving one or more pumps, then removes the air.

This step is critical because it eliminates reactive gases, primarily oxygen and nitrogen. By removing them, the furnace prevents oxidation, discoloration, and other unwanted chemical reactions on the material's surface.

Stage 2: Heating - Precision Through Radiation

Once the desired vacuum level is reached, the electric heating elements are activated. These elements, often made of graphite or refractory metals, surround the workload without touching it.

In the vacuum, there is no air to transfer heat via convection. Instead, heat is transferred almost entirely through thermal radiation. This method results in highly uniform and consistent heating, as energy radiates from the elements to the material from all sides.

Stage 3: Soaking - The Transformation Phase

"Soaking" is the phase where the material is held at a specific target temperature for a predetermined amount of time. The temperature, which can range from 500°C to over 2,500°C, is precisely regulated by the furnace's control system.

This is where the intended material transformation—such as sintering, brazing, annealing, or hardening—takes place in a perfectly controlled and clean environment.

Stage 4: Cooling - Locking in the Properties

After the soaking phase, the heating elements are turned off. The material is then cooled in a controlled manner, either by letting it radiate its heat away slowly or by introducing an inert gas like argon or nitrogen to speed up the process.

The cooling rate is just as critical as the heating rate for determining the final microstructure and physical properties of the material.

Understanding the Trade-offs and Limitations

While powerful, a vacuum furnace is a specialized tool. Understanding its inherent trade-offs is key to using it effectively.

Advantage: Unmatched Purity

The primary benefit is the elimination of contamination. For reactive metals like titanium or high-purity alloys used in aerospace and medical implants, heating in a vacuum is not just beneficial—it's often the only option.

Advantage: Superior Uniformity and Control

Radiant heating in a vacuum provides exceptionally even temperature distribution across the part. This uniformity, combined with precise digital controls, allows for highly repeatable results and the creation of specific, desirable microstructures.

Disadvantage: Cost and Complexity

Vacuum furnaces are significantly more complex and expensive than their atmospheric counterparts. The need for a sealed chamber, robust vacuum pumps, and sophisticated control systems adds to both the initial investment and ongoing maintenance costs.

Disadvantage: Slower Cycle Times

The evacuation step adds time to every cycle. Pumping a large chamber down to a deep vacuum can be a lengthy process, making vacuum furnaces less suitable for high-volume, rapid heat-treating operations where atmospheric contamination is not a concern.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your material and desired outcome.

- If your primary focus is processing reactive metals (like titanium) or high-purity materials: A vacuum furnace is essential to prevent the oxidation and contamination that would compromise the material's integrity.

- If your primary focus is high-precision brazing or sintering: The clean environment and uniform heating of a vacuum furnace ensure strong, void-free joints and dense, consistent parts.

- If your primary focus is low-cost, bulk heat treatment of common steels: A conventional atmospheric furnace is often the more practical and cost-effective solution, as minor surface oxidation is acceptable or can be removed later.

Ultimately, understanding the function of a vacuum furnace is to understand the power of controlling the environment to achieve perfect material transformation.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Evacuation | Remove air/gases to create a vacuum | Eliminate oxygen & nitrogen to prevent oxidation/contamination |

| 2. Heating | Electric elements heat via thermal radiation | Achieve uniform, consistent temperature without convection |

| 3. Soaking | Hold at precise target temperature | Enable material transformation (sintering, brazing, annealing) |

| 4. Cooling | Controlled cooling via radiation or inert gas | Lock in final material microstructure and properties |

Need a high-temperature furnace for pure, precise thermal processing?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced vacuum furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for sintering, brazing, or annealing high-purity materials.

Contact our experts today to discuss how we can help you achieve perfect material transformation.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance