A high-precision vacuum sealing system is critical for CrSb processing because it establishes the strict environmental controls necessary to prevent chemical degradation. By evacuating quartz tubes and backfilling them with an inert gas like argon, the system eliminates oxygen that would otherwise destroy the precursor materials. Additionally, it secures the internal pressure stability required to successfully grow high-purity single crystals.

The synthesis of Chromium Antimonide (CrSb) allows for zero tolerance of atmospheric contamination. A high-precision vacuum system is the foundational tool that prevents oxidation at high temperatures and stabilizes the pressure needed for the chemical transport process.

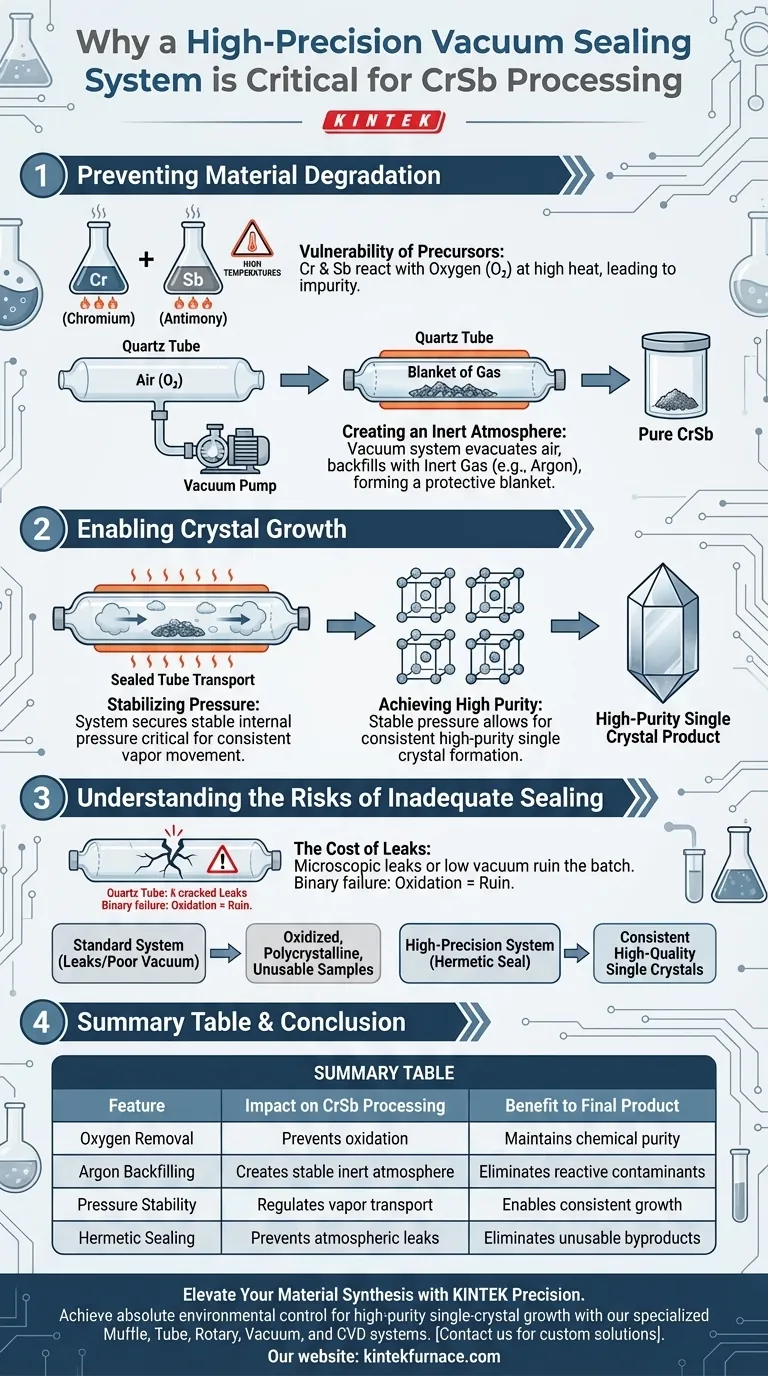

Preventing Material Degradation

The Vulnerability of Precursors

Chromium and antimony are chemically reactive materials, particularly when subjected to the high temperatures required for synthesis.

If exposed to even trace amounts of oxygen during heating, these elements will oxidize. This chemical reaction fundamentally alters the precursors, preventing the formation of the desired CrSb compound and resulting in impure, unusable byproducts.

Creating an Inert Atmosphere

To counteract this, the vacuum system must evacuate air from the quartz tubes used for processing.

Once the air is removed, the tubes are backfilled with an inert gas, typically argon. This substitution creates a "blanket" around the materials, ensuring that when the temperature rises, there is no oxygen available to react with the chromium or antimony.

Enabling Crystal Growth

Stabilizing Pressure

Beyond simple protection, the vacuum sealing process plays an active role in the transport process.

The synthesis of single-crystal products relies on the movement of vaporized material within the sealed tube. This transport is highly sensitive to pressure differentials. A high-precision system ensures the internal pressure remains stable throughout the process, allowing for consistent crystal growth.

Achieving High Purity

The ultimate goal of this rigorous process is the production of high-purity single-crystal products.

Any fluctuation in pressure or introduction of contaminants disrupts the crystal lattice formation. The precision of the sealing system is the primary safeguard against these disruptions, ensuring the final product meets the necessary quality standards.

Understanding the Risks of Inadequate Sealing

The Cost of Leaks

The term "high-precision" is not merely descriptive; it is a functional requirement.

A standard or low-quality sealing system may leave microscopic leaks or fail to achieve a sufficient vacuum level. In CrSb processing, this failure is binary: if oxygen enters or pressure destabilizes, the batch is effectively ruined. There is rarely a "partial success" when oxidation occurs.

Sensitivity to Environment

The process assumes a controlled environment inside the quartz tube.

If the initial evacuation is incomplete, or if the backfilling with argon is imprecise, the internal conditions will deviate from the synthesis requirements. This leads to poor transport rates and polycrystalline or heavily oxidized samples rather than single crystals.

Ensuring Synthesis Success

The choice of vacuum system directly dictates the quality of your final material.

- If your primary focus is Chemical Purity: Ensure the system is capable of high-vacuum evacuation to remove all traces of oxygen before argon backfilling.

- If your primary focus is Crystal Structure: Prioritize a system that guarantees hermetic sealing to maintain stable pressure dynamics during the transport phase.

Precision in the sealing stage is the single most important factor in transitioning from raw precursors to high-quality CrSb crystals.

Summary Table:

| Feature | Impact on CrSb Processing | Benefit to Final Product |

|---|---|---|

| Oxygen Removal | Prevents oxidation of Chromium & Antimony | Maintains chemical purity and compound integrity |

| Argon Backfilling | Creates a stable inert atmosphere | Eliminates reactive contaminants during heating |

| Pressure Stability | Regulates vapor transport dynamics | Enables consistent high-quality single-crystal growth |

| Hermetic Sealing | Prevents atmospheric leaks | Eliminates risk of unusable, oxidized byproducts |

Elevate Your Material Synthesis with KINTEK Precision

Don't let atmospheric contamination ruin your CrSb precursors. At KINTEK, we understand that high-purity single-crystal growth requires absolute environmental control. Backed by expert R&D and manufacturing, we offer specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your specific high-temperature laboratory needs.

Whether you need to achieve high-vacuum evacuation or maintain hermetic pressure stability, our high-temp furnaces provide the reliability your research demands. Contact us today to find your custom solution and ensure the success of your next synthesis batch.

Visual Guide

References

- B. Rai, Nitesh Kumar. Direction‐Dependent Conduction Polarity in Altermagnetic CrSb. DOI: 10.1002/advs.202502226

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum pyrolysis furnace in lunar ceramic 3D printing? High-Precision Debinding Solutions

- What is the function of a Vacuum or Inert Gas Brazing Furnace? Ensure High-Integrity Energy Equipment Seals

- What is the purpose of a vacuum furnace? Achieve Superior Material Quality and Purity

- Why is a two-stage vacuum unit used in waste magnesium distillation? Optimize Pumping Speed and Process Stability

- What are the primary differences in sintering strategies for ceramic membranes? Optimize Your Thermal Processing

- How are vacuum furnaces used in the preparation of special alloys? Unlock Purity and Performance

- What materials are compatible with high vacuum furnaces? Essential Guide for Aerospace, Medical, and Electronics

- What are the two common hot zone configurations in vertical vacuum furnaces? Compare Graphite vs. All-Metal