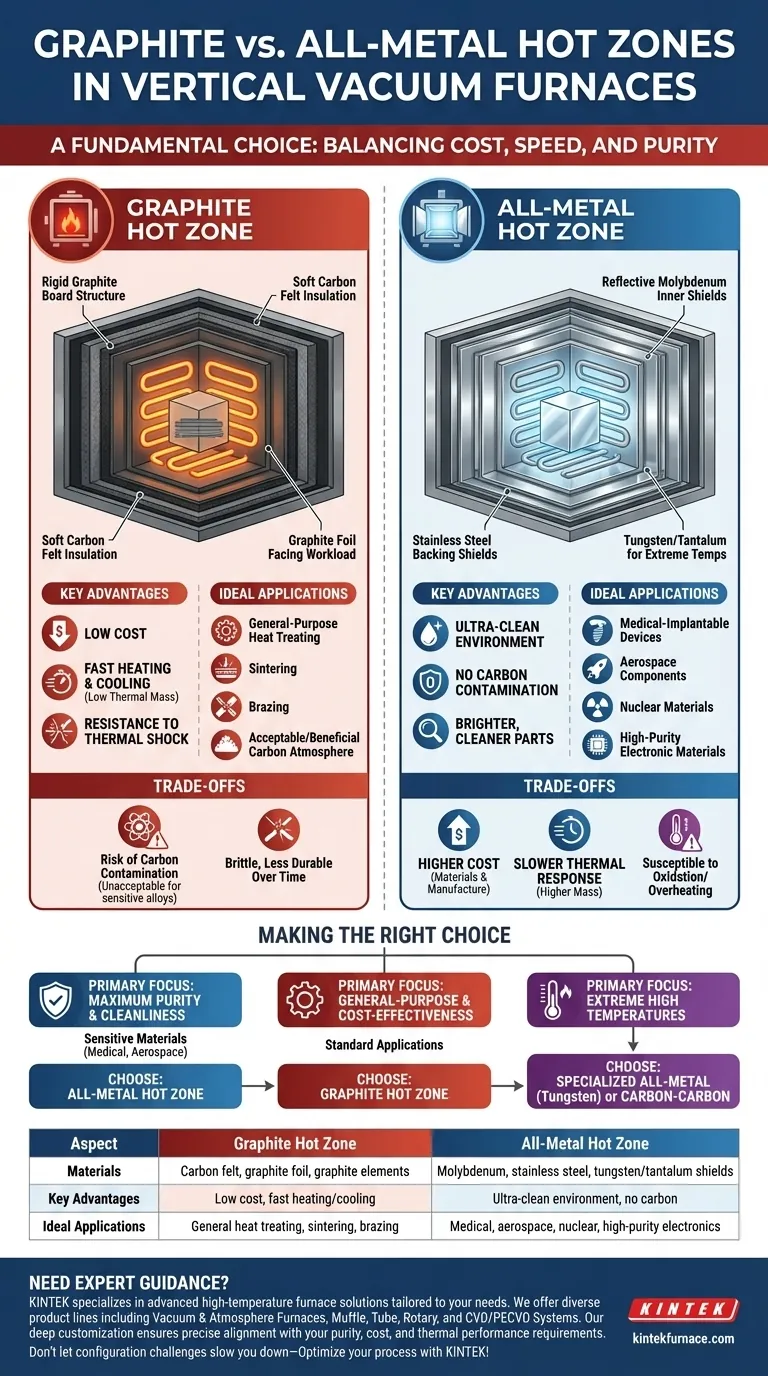

In vertical vacuum furnaces, the two most common hot zone configurations are graphite-based and all-metal. Graphite hot zones are constructed from layers of carbon felt and graphite foil, while all-metal versions use reflective sheets of materials like molybdenum and stainless steel to contain the heat. Both designs serve the same function but are suited for distinctly different applications and operating conditions.

The choice between a graphite and an all-metal hot zone is a fundamental decision that defines the furnace's capabilities. It is a trade-off between the cost-effectiveness and rapid thermal response of graphite versus the superior cleanliness and purity of an all-metal environment.

Understanding Graphite Hot Zones

A graphite hot zone is the workhorse of the vacuum furnace industry, prized for its economic and thermal performance in a wide range of applications.

Construction and Materials

Graphite hot zones are built using layers of carbon-based insulation. This typically includes rigid graphite board for structure, surrounded by layers of soft carbon felt and a final layer of graphite foil facing the workload. The heating elements themselves are also made of graphite.

Key Advantages

The primary advantages of graphite are its low cost, low thermal mass, and resistance to thermal shock. This allows for very fast heating and cooling rates, which can significantly shorten process cycle times.

Ideal Applications

Graphite is the standard choice for general-purpose heat treating, sintering, and brazing processes where a slight carbon-rich atmosphere is acceptable or even beneficial. It excels in applications that prioritize throughput and cost-efficiency.

Understanding All-Metal Hot Zones

All-metal hot zones are engineered for applications where process purity is the most critical factor. They create an exceptionally clean high-vacuum environment.

Construction and Materials

Instead of absorptive insulation, an all-metal hot zone uses multiple layers of reflective metal sheets. Common materials include molybdenum for the inner layers closest to the heat, backed by stainless steel shields. Tungsten or tantalum may be used for extremely high-temperature applications.

Key Advantages

The defining benefit is an "ultra-clean" processing environment. There is no fibrous insulation to outgas or shed particles, and the absence of carbon eliminates the risk of carbon contamination of the workload. This results in brighter, cleaner parts.

Ideal Applications

These hot zones are essential for processing medically-implantable devices, aerospace components, nuclear materials, and high-purity electronic materials. Any process involving materials highly sensitive to carbon, such as certain nickel-based superalloys, demands an all-metal design.

Understanding the Trade-offs

Neither configuration is universally superior; the correct choice depends entirely on the process requirements and material being treated.

Purity vs. Contamination

This is the most significant trade-off. An all-metal hot zone provides the cleanest possible environment. A graphite hot zone, by its nature, can introduce trace amounts of carbon into the vacuum atmosphere, which is unacceptable for sensitive alloys.

Cost and Durability

Graphite components are significantly less expensive to manufacture and replace. However, graphite can become brittle over time and is susceptible to damage. Metal shields are more expensive upfront but are generally more durable, provided they are not operated in an oxidizing atmosphere or overheated.

Thermal Performance

Graphite's low mass allows for faster ramp-up and cool-down. The higher mass of metal shields means they heat and cool more slowly. However, the uniform reflectivity of a metal hot zone can sometimes provide more precise temperature uniformity across the workload.

Making the Right Choice for Your Process

Your process goals will directly dictate the ideal hot zone configuration for your vertical vacuum furnace.

- If your primary focus is maximum purity and cleanliness: An all-metal hot zone is the only choice to avoid carbon contamination for sensitive materials like medical implants or aerospace alloys.

- If your primary focus is general-purpose heat treating and cost-effectiveness: A graphite hot zone provides excellent performance, faster cycle times, and lower operational costs for a majority of standard applications.

- If your primary focus is processing at extremely high temperatures: You must choose a configuration with materials rated for that range, such as a tungsten all-metal hot zone or a specialized carbon-carbon composite design.

Ultimately, selecting the right hot zone is the foundational step in ensuring your heat-treating process is both successful and repeatable.

Summary Table:

| Aspect | Graphite Hot Zone | All-Metal Hot Zone |

|---|---|---|

| Materials | Carbon felt, graphite foil, graphite elements | Molybdenum, stainless steel, tungsten/tantalum shields |

| Key Advantages | Low cost, low thermal mass, fast heating/cooling | Ultra-clean environment, no carbon contamination |

| Ideal Applications | General-purpose heat treating, sintering, brazing | Medical implants, aerospace, nuclear, high-purity electronics |

| Trade-offs | Risk of carbon contamination, less durable | Higher cost, slower thermal response |

Struggling to choose the right hot zone for your vertical vacuum furnace? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your experimental requirements, whether you prioritize purity, cost-efficiency, or thermal performance. Don't let configuration challenges slow you down—contact us today to optimize your heat-treating process and achieve superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments