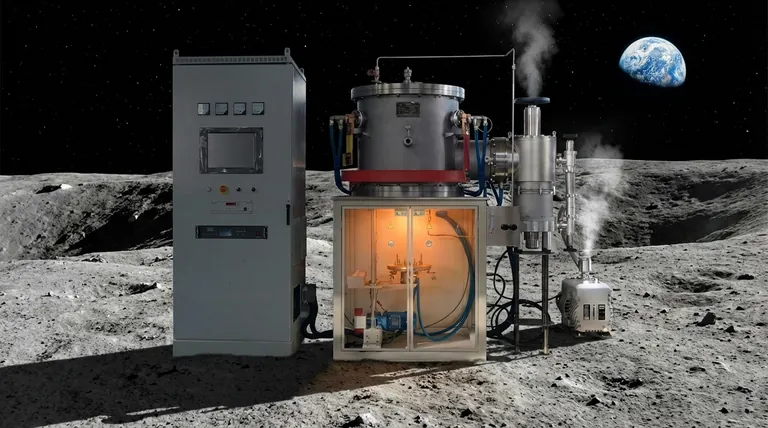

The vacuum pyrolysis furnace serves as the critical conversion stage in the lunar ceramic 3D printing workflow. Its primary function is to facilitate debinding, a process where temporary polymer binders used during printing are thermally decomposed and volatilized in a controlled vacuum environment to leave behind a pure ceramic structure.

The furnace transforms polymer-heavy "green" parts into inorganic ceramics through precise thermal decomposition. It is essential for managing the release of volatile gases, ensuring the material converts to a stable ceramic without suffering structural cracks.

Transforming Matter: The Debinding Process

Converting Polymers to Ceramics

In workflows utilizing precursor-derived ceramics or light-curing, the initial printed object relies on polymers to hold its shape. The vacuum pyrolysis furnace heats these parts to break down the organic polymer components. This chemical decomposition converts the material into stable, inorganic residues, such as SiOC (Silicon Oxycarbide) ceramics.

Achieving Material Purity

The process operates under a vacuum to strictly control the atmosphere around the printed part. This allows for the clean removal (volatilization) of the decomposed polymer binders. This step is vital to ensure the final component consists of pure ceramic material without organic contaminants.

Preserving Structural Integrity

Controlled Gas Release

As the polymers inside the printed part decompose, they turn into gas and expand. If this happens too quickly, the internal pressure can shatter the object. The furnace manages this environment to allow gases to escape at a safe, controlled rate.

Precise Temperature Regulation

The integrity of the final part is dictated by thermal precision. The furnace employs precise temperature control to avoid sudden spikes in heat. This gradual approach prevents the structural cracking that often occurs when gases escape violently during rapid decomposition.

Understanding the Trade-offs

The Risk of Thermal Speed

While the furnace is designed for conversion, it introduces a bottleneck regarding speed. You cannot rush the pyrolysis process; rapid heating triggers the rapid escape of gases. This leads to immediate structural failure or micro-cracking, rendering the printed component useless for high-stress applications.

Complexity of Atmosphere Control

Vacuum pyrolysis requires distinct atmospheric conditions compared to standard sintering. While sintering furnaces (mentioned in general ceramic production) fuse particles, this specific furnace must first strip away binders. Failing to maintain a sufficient vacuum during this stage can result in incomplete debinding and weak final parts.

Making the Right Choice for Your Workflow

To maximize the success rate of your ceramic prints, tailor your furnace settings to your specific requirements:

- If your primary focus is material purity: prioritize high vacuum levels to ensure complete volatilization of all polymer binders and residues.

- If your primary focus is structural survival: prioritize extended cycle times with slow temperature ramp rates to mitigate the stress of gas expansion.

The vacuum pyrolysis furnace is the bridge between a fragile printed shape and a durable, high-performance ceramic asset.

Summary Table:

| Stage | Key Function | Benefit for Lunar Ceramics |

|---|---|---|

| Debinding | Thermal decomposition of polymer binders | Converts "green" parts into pure inorganic structures |

| Vacuum Control | Precise atmospheric regulation | Ensures clean volatilization and high material purity |

| Gas Management | Regulated release of volatile gases | Prevents structural cracking and internal pressure buildup |

| Thermal Ramp | Gradual, precise heating profiles | Preserves structural integrity for high-stress applications |

Elevate Your Advanced Ceramic Manufacturing with KINTEK

Transitioning from complex 3D-printed shapes to high-performance ceramic assets requires absolute thermal precision. Backed by expert R&D and world-class manufacturing, KINTEK provides specialized Vacuum, CVD, and Muffle systems designed to master the critical debinding and pyrolysis stages. Whether you are developing lunar ceramic prototypes or industrial components, our customizable lab high-temperature furnaces ensure material purity and structural integrity.

Ready to optimize your ceramic workflow? Contact our experts today to discover how KINTEK’s tailored thermal solutions can drive your innovation forward.

Visual Guide

References

- Alex Ellery. Ceramics—The Forgotten but Essential Ingredients for a Circular Economy on the Moon. DOI: 10.3390/ceramics8030107

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How is temperature controlled in a vacuum furnace? Achieve Precise Heat Treatment for Your Materials

- What operational flexibility do multiple-chamber vacuum furnaces provide? Boost Efficiency with Continuous Processing

- Why Multiple Vacuum & Argon Cycles for High-Entropy Alloys? Achieve Peak Purity & Chemical Precision!

- What are the functions of a heat shield in a vacuum sintering furnace? Essential for Thermal Control and Efficiency

- What is the purpose of using a laboratory vacuum drying oven for post-processing lignin nanofiber membranes?

- What is the purpose of using a high-temperature vacuum sintering furnace? Unlock Boron Nitride Thermal Performance

- What are the benefits of the vacuum furnace's insulation materials? Boost Efficiency and Precision

- How does a bidirectional alternating cyclic gas quenching system improve results? Eliminate the Shadow Effect