A bidirectional alternating cyclic gas quenching system significantly improves process reliability by actively eliminating the "shadow effect" that plagues traditional unidirectional setups. By periodically switching the gas flow between top-down and bottom-up directions, the system prevents the upper layers of a stack from blocking airflow to the lower layers. This ensures that every gear in a batch experiences the same thermal history, regardless of its position in the stack.

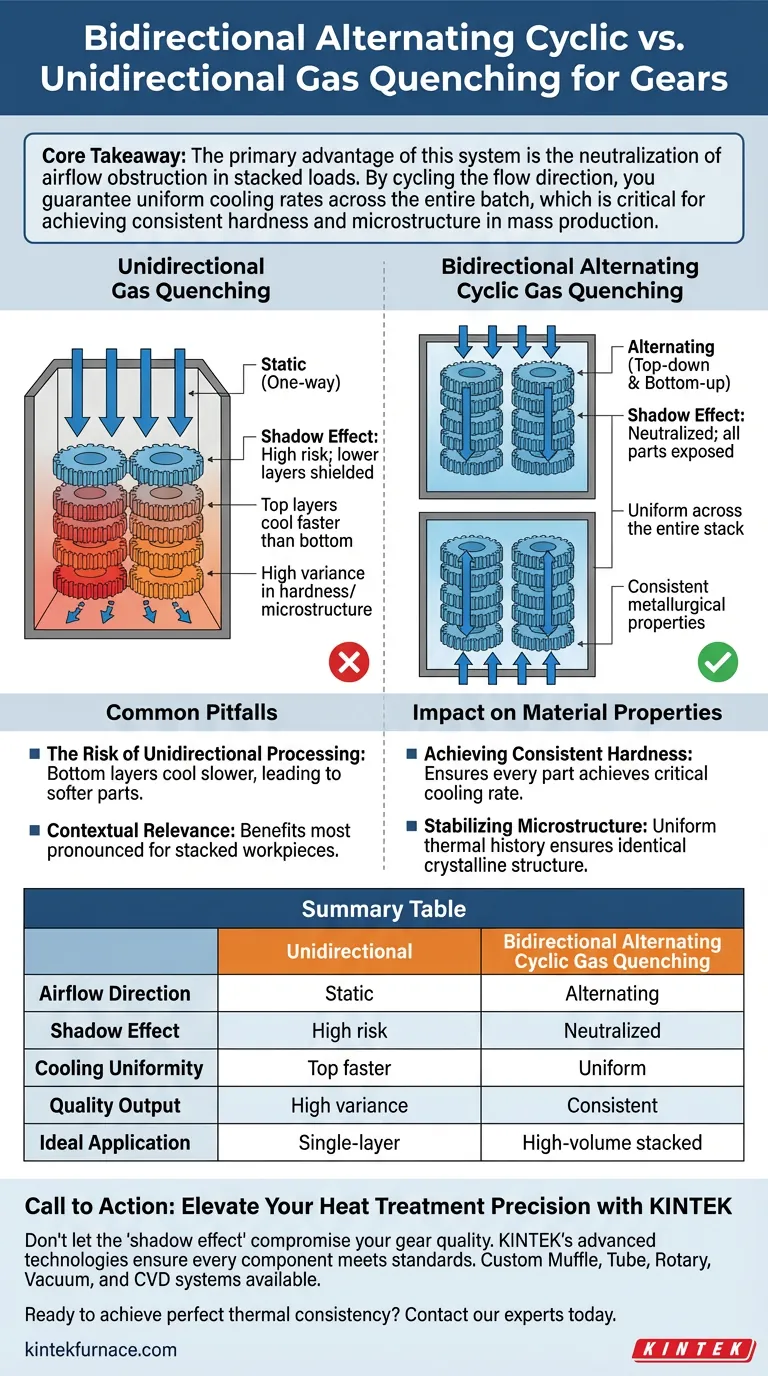

Core Takeaway: The primary advantage of this system is the neutralization of airflow obstruction in stacked loads. By cycling the flow direction, you guarantee uniform cooling rates across the entire batch, which is critical for achieving consistent hardness and microstructure in mass production.

The Mechanics of Uniform Cooling

overcoming the Shadow Effect

In a standard unidirectional system, the gas flows from one source, typically the top. The first layer of gears strikes the gas stream first, effectively shielding or "shadowing" the components beneath them.

The Alternating Flow Solution

A bidirectional system disrupts this static pattern by periodically reversing the airflow. By alternating between top-down and bottom-up blowing, the system ensures that the "shadowed" areas are exposed to direct cooling currents.

Eliminating Thermal Gradients

This cyclic movement balances the heat extraction across the entire load. It prevents the top layers from cooling significantly faster than the bottom layers, a common cause of distortion and inconsistency.

Impact on Material Properties

Achieving Consistent Hardness

The hardness of a gear is directly dictated by how quickly it is cooled. Because the bidirectional system equalizes the airflow, it ensures every part in the stack achieves the same critical cooling rate.

Stabilizing Microstructure

Microstructure depends entirely on the thermal history of the part. Uniform heating and cooling ensure that the crystalline structure of the metal is identical across the batch.

Reliability in Mass Production

For high-volume manufacturing, part-to-part consistency is the metric of success. This system removes the variable of "position in the stack" from the quality equation.

Common Pitfalls to Avoid

The Risk of Unidirectional Processing

If you rely on unidirectional flow for stacked gears, you accept a high risk of variance. The bottom layers will almost invariably cool slower, leading to softer parts and potential rejection.

Contextual Relevance

It is important to note that this technology is specifically designed to address stacked workpieces. The benefits are most pronounced when airflow blockage is a physical reality of your loading configuration.

Making the Right Choice for Your Goal

To determine if this system aligns with your processing needs, consider your specific production constraints:

- If your primary focus is Mass Production of Stacked Loads: Adopt bidirectional quenching to maximize throughput while eliminating the "shadow effect" that compromises lower layers.

- If your primary focus is Metallurgical Consistency: Use this system to ensure that cooling rates, hardness, and microstructure are identical across the entire batch, reducing quality control failures.

By controlling the direction of flow, you transform a variable process into a predictable one.

Summary Table:

| Feature | Unidirectional Gas Quenching | Bidirectional Cyclic Quenching |

|---|---|---|

| Airflow Direction | Static (One-way) | Alternating (Top-down & Bottom-up) |

| Shadow Effect | High risk; lower layers shielded | Neutralized; all parts exposed |

| Cooling Uniformity | Top layers cool faster than bottom | Uniform across the entire stack |

| Quality Output | High variance in hardness/microstructure | Consistent metallurgical properties |

| Ideal Application | Single-layer/Low-density loads | High-volume, stacked workpiece batches |

Elevate Your Heat Treatment Precision with KINTEK

Don't let the "shadow effect" compromise your gear quality. KINTEK’s advanced quenching technologies ensure every component in your batch meets rigorous hardness and microstructure standards. Backed by expert R&D and manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific industrial requirements.

Ready to achieve perfect thermal consistency? Contact our experts today to discover how our customizable lab and industrial high-temp furnaces can transform your production reliability.

Visual Guide

References

- Zaiyong Ma, Jingbo Ma. Research on the uniformity of cooling of gear ring parts under vacuum high-pressure gas quenching. DOI: 10.1088/1742-6596/3080/1/012130

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the primary purpose of using industrial-grade stainless steel pressure vessels? Optimize Wood Modification

- How does the atmosphere in a high vacuum sintering furnace affect 17-4PH properties? Optimize Density and Hardness

- How can vacuum furnace chillers reduce operating costs? Boost Efficiency and Cut Hidden Expenses

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the main components of a drop-bottom quench furnace? Essential Parts for Rapid Heat Treatment

- What are the environmental requirements for vacuum sintering? Achieve Superior Material Density and Purity

- What is vacuum carburizing or low pressure carburizing (LPC)? Unlock Precision Case Hardening for Steel

- How does increasing the vacuum furnace annealing temperature to 900 K adversely affect Ti–TEG composites?