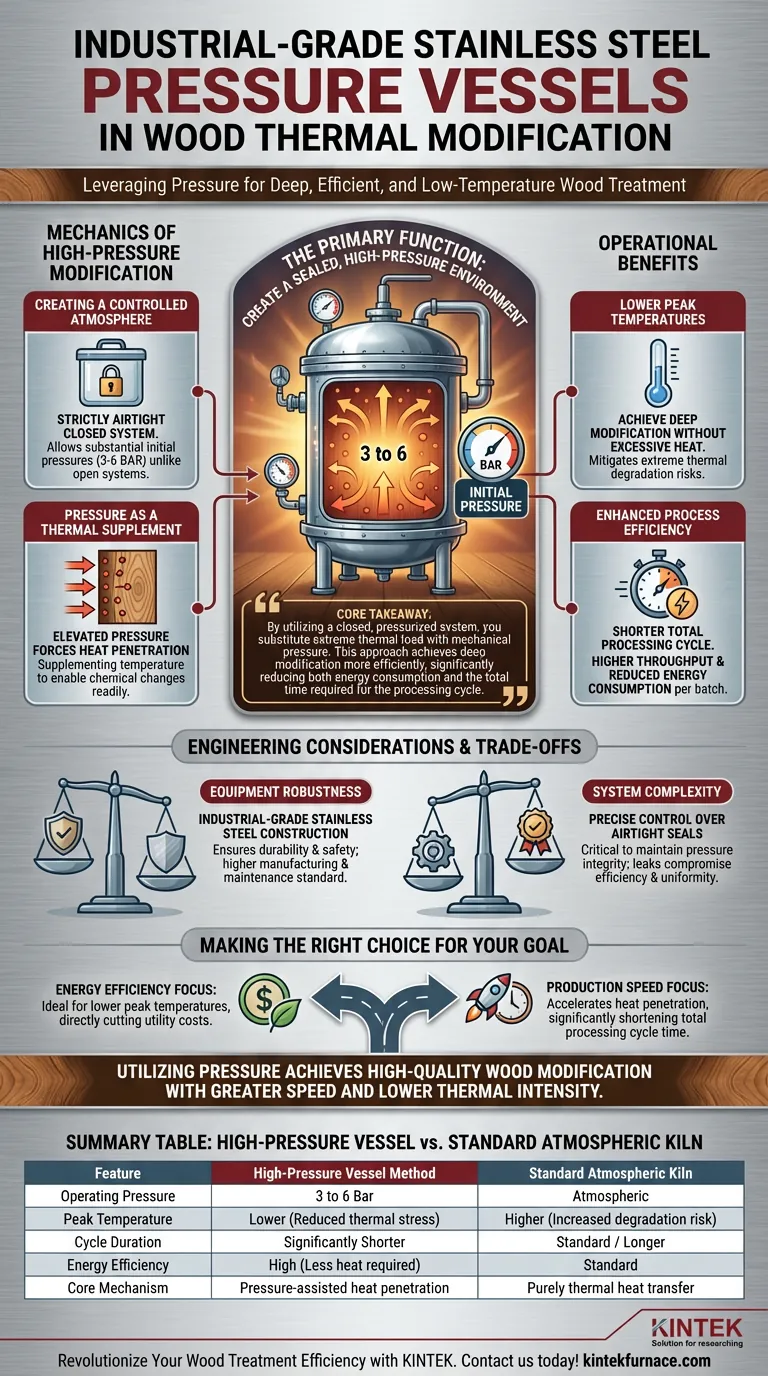

The primary function of industrial-grade stainless steel pressure vessels in wood thermal modification is to create a sealed, high-pressure environment that fundamentally alters how heat interacts with the wood. By maintaining an initial pressure between 3 and 6 bar, these vessels allow pressure to act as a catalyst, enabling deep thermal modification to occur at lower peak temperatures than standard atmospheric kilns.

Core Takeaway By utilizing a closed, pressurized system, you substitute extreme thermal load with mechanical pressure. This approach achieves deep modification more efficiently, significantly reducing both energy consumption and the total time required for the processing cycle.

The Mechanics of High-Pressure Modification

Creating a Controlled Atmosphere

The vessel provides a strictly airtight environment essential for the modification process.

Unlike open systems, this closed system allows operators to introduce and maintain substantial initial pressures, typically in the range of 3 to 6 bar.

Pressure as a Thermal Supplement

In this environment, pressure serves as a critical supplement to temperature.

Rather than relying solely on heat transfer to penetrate the wood, the elevated pressure forces heat into the material more effectively. This synergy allows the chemical changes associated with thermal modification to occur more readily.

Operational Benefits

Lower Peak Temperatures

The primary advantage of adding pressure is the ability to achieve deep thermal modification without subjecting the wood to excessive heat.

By lowering the peak temperature required for the process, you mitigate the risks associated with extreme thermal degradation while still altering the wood's properties to the desired depth.

Enhanced Process Efficiency

The combination of pressure and heat accelerates the modification reaction.

This results in a noticeably shorter total processing cycle, allowing for higher throughput. Additionally, because lower temperatures are required to achieve the same results, the overall energy consumption for each batch is reduced.

Engineering Considerations and Trade-offs

Equipment Robustness

Implementing a system capable of sustaining 3 to 6 bar requires industrial-grade stainless steel construction.

While this ensures durability and safety, it necessitates a higher standard of manufacturing and maintenance compared to non-pressurized thermal kilns.

System Complexity

The "closed system" nature of these vessels demands precise control over the airtight seals.

Maintaining the integrity of the pressure environment is critical; any leaks can compromise the efficiency gains and the uniformity of the wood treatment.

Making the Right Choice for Your Goal

Adopting pressure vessel technology shifts the modification process from a purely thermal challenge to a thermo-mechanical one.

- If your primary focus is energy efficiency: This system is ideal because it achieves deep modification results at lower peak temperatures, directly cutting utility costs.

- If your primary focus is production speed: The pressurized environment accelerates heat penetration, significantly shortening the total processing cycle time.

Utilizing pressure as a process variable allows you to achieve high-quality wood modification with greater speed and lower thermal intensity.

Summary Table:

| Feature | High-Pressure Vessel Method | Standard Atmospheric Kiln |

|---|---|---|

| Operating Pressure | 3 to 6 Bar | Atmospheric |

| Peak Temperature | Lower (Reduced thermal stress) | Higher (Increased degradation risk) |

| Cycle Duration | Significantly Shorter | Standard / Longer |

| Energy Efficiency | High (Less heat required) | Standard |

| Core Mechanism | Pressure-assisted heat penetration | Purely thermal heat transfer |

Revolutionize Your Wood Treatment Efficiency with KINTEK

Are you looking to achieve deep thermal modification while cutting energy costs and production time? KINTEK provides high-performance, industrial-grade stainless steel pressure vessels engineered to withstand rigorous thermal cycles.

Backed by expert R&D and world-class manufacturing, we offer customizable Vacuum, Pressure, and Lab High-Temp Furnace systems tailored to your specific wood modification requirements. Our technology allows you to substitute extreme thermal loads with precise mechanical pressure, ensuring superior material properties and faster throughput.

Ready to upgrade your thermal processing? Contact us today to discuss your unique needs with our specialist engineering team!

Visual Guide

References

- Guntis Sosins, Jānis Zicāns. Water-Related Properties of Wood after Thermal Modification in Closed Process under Pressure in Nitrogen. DOI: 10.3390/f15010140

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Can you describe a process example using a vacuum hardening furnace? Achieve Clean, Precise Metal Hardening

- How is a vacuum drying oven utilized in the pretreatment of expanded graphite? Optimize Your PCM Composite Quality

- How does vacuum brazing prevent oxidation and contamination? Achieve Clean, Strong Joints for Critical Applications

- What role does a vacuum furnace play in Mg3Sb2 preparation? Optimize Purity and Performance

- Why is a segmented PID control system necessary for lithium battery vacuum drying? Ensure Precision & Safety

- What are the specifications for medium frequency induction heating in vacuum graphitizing furnaces? | KINTEK

- How does a high-temperature austenitization furnace ensure structural transformation? Mastering Fe-5%Mn-C Quenching