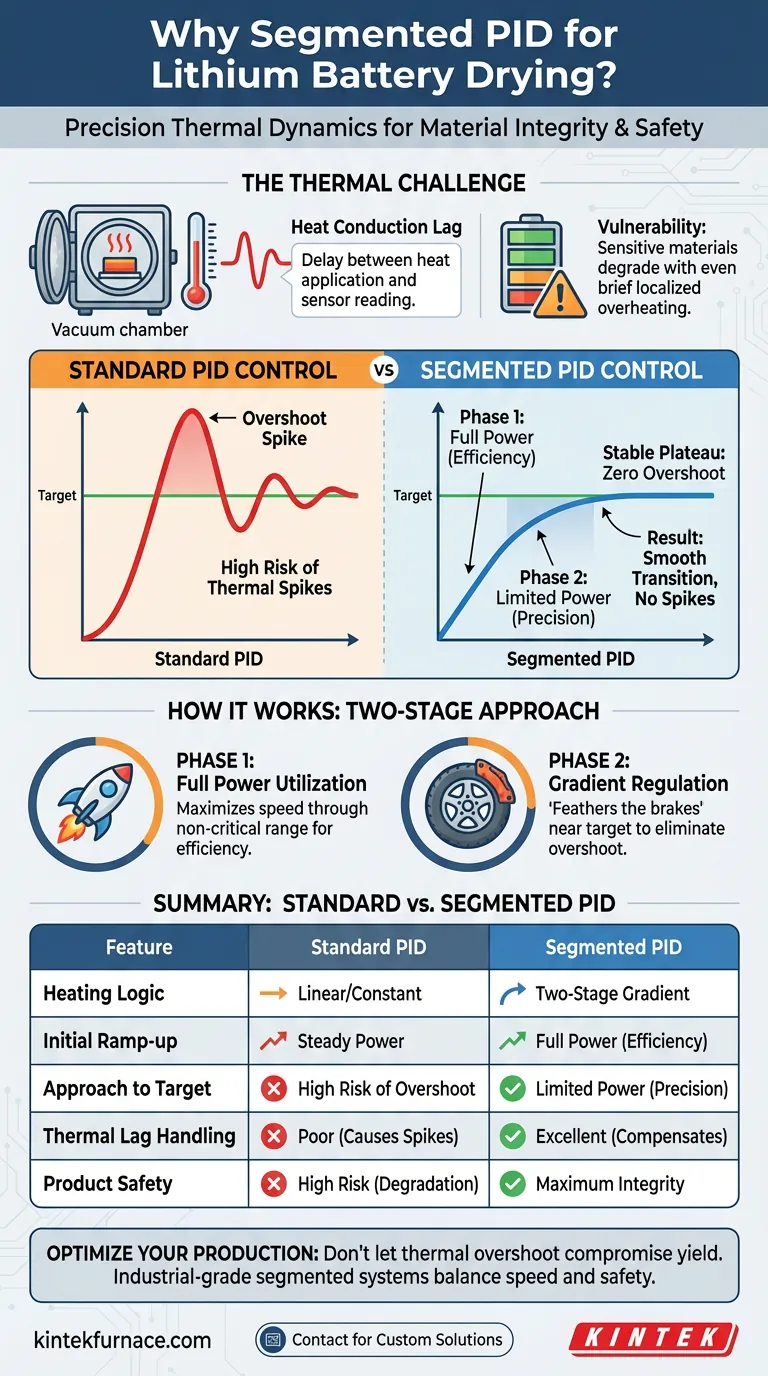

A segmented PID control system is strictly necessary to manage the critical thermal dynamics of drying lithium batteries without damaging them. It operates by precisely regulating the heating power gradient, utilizing full power for the initial ramp-up and then automatically switching to limited power as the temperature nears its target. This two-stage approach counteracts heat conduction lag, preventing the temperature spikes that destroy sensitive battery chemistry.

The core function of this system is to decouple heating speed from thermal precision. By throttling power before the target is reached, it eliminates temperature overshoot, ensuring the battery materials are dried efficiently without being subjected to destructive localized overheating.

The Thermal Challenge in Vacuum Drying

Understanding Heat Conduction Lag

In a vacuum drying process, there is a physical delay between applying heat and the temperature sensor registering the change.

This phenomenon, known as heat conduction lag, makes standard control systems risky. By the time a standard controller realizes the target temperature is reached, the residual heat in the heating element causes the temperature to keep rising.

The Vulnerability of Lithium Materials

Lithium battery components are highly sensitive to thermal stress.

Even brief periods of localized overheating can degrade the materials. This compromises the battery's performance and safety before it even leaves the factory.

How Segmented PID Solves the Problem

Phase 1: Full Power Utilization

During the initial phase of the cycle, the industrial-grade system applies full power.

This is essential for efficiency. It drives the temperature up quickly through the safe non-critical range to minimize total cycle time.

Phase 2: Gradient Regulation

As the temperature approaches the specific target setpoint, the system shifts to limited power.

This effectively "feathers the brakes" on the heating process. It reduces the energy input to align with the thermal inertia of the system.

Result: The Smooth Transition

This segmentation ensures a smooth entry into the constant temperature state.

Instead of oscillating around the target (overshooting and undershooting), the temperature creates a stable plateau. This stability is required to dry the battery effectively without thermal spikes.

Operational Considerations

Balancing Speed and Safety

The primary trade-off in this approach is the relationship between ramp-up speed and protection.

While keeping a system on full power until the last second might theoretically be faster, the risk of overshoot makes it non-viable for lithium batteries. The segmented approach sacrifices a fraction of ramp speed at the very end to guarantee zero damage to the product.

The Necessity of Industrial-Grade Logic

Not all PID controllers can handle this segmentation effectively.

Standard controllers often react linearly. An industrial-grade segmented system is required to define distinct power output zones based on the specific proximity to the target temperature.

Making the Right Choice for Your Process

If your primary focus is Production Throughput:

- Rely on the "Phase 1" capability of the system to maximize heating speed during the initial non-critical temperature range.

If your primary focus is Product Yield and Safety:

- Prioritize the calibration of the "Phase 2" power limitation to ensure the transition to constant temperature is completely flat with no overshoot.

Precise thermal regulation is not merely an efficiency tool; it is a fundamental requirement for preserving the integrity of lithium battery materials.

Summary Table:

| Feature | Standard PID Control | Segmented PID Control |

|---|---|---|

| Heating Logic | Linear/Constant | Two-Stage Gradient |

| Initial Ramp-up | Steady Power | Full Power (Efficiency) |

| Approach to Target | High Risk of Overshoot | Limited Power (Precision) |

| Thermal Lag Handling | Poor - Causes Spikes | Excellent - Compensates for Inertia |

| Product Safety | High Risk of Degradation | Maximum Material Integrity |

Optimize Your Battery Production with KINTEK

Don't let thermal overshoot compromise your product yield. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lithium-ion research or production needs. Our advanced thermal solutions are designed to handle the most sensitive materials with industrial-grade precision.

Ready to elevate your thermal processing? Contact us today to discuss your custom furnace requirements with our engineering team!

Visual Guide

References

- Lili Zhao, Bo Qi. Research on Temperature Field Characteristics of Lithium Battery Vacuum Drying Furnace. DOI: 10.56028/aetr.11.1.63.2024

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How is multi-zone heating achieved in vacuum furnaces? Master Precise Temperature Control for Uniform Heating

- What is a heat treatment vacuum furnace? Achieve Superior Material Purity and Performance

- What industries benefit from High Vacuum Melting Furnaces? Unlock Purity for Aerospace, Biomedical & More

- Why is the Vacuum Degassing process critical when refining liquid H13 tool steel? Ensure Purity and Durability

- What is a laboratory vacuum furnace and what environment does it create? Achieve Purity in High-Temp Processing

- What are some applications of graphite materials in vacuum furnace processing? Discover Key Uses and Benefits

- What are the technical advantages of using a high vacuum furnace for Si3N4/Al-Cu composites? Superior Sintering Quality

- What heating method is proposed for the vacuum chamber? Efficient Direct Resistive Heating Explained