In essence, a heat treatment vacuum furnace is a specialized chamber that performs metallurgical processes in a near-total vacuum instead of in open air. This equipment combines high-temperature heating with vacuum technology to precisely alter a material's properties. By removing the atmosphere, it prevents unwanted chemical reactions like oxidation, enabling superior results that are often impossible to achieve with conventional furnaces.

The core value of a vacuum furnace isn't just the heat it provides, but the atmosphere it removes. By eliminating reactive gases like oxygen, it offers unparalleled control over a material's final integrity, purity, and performance.

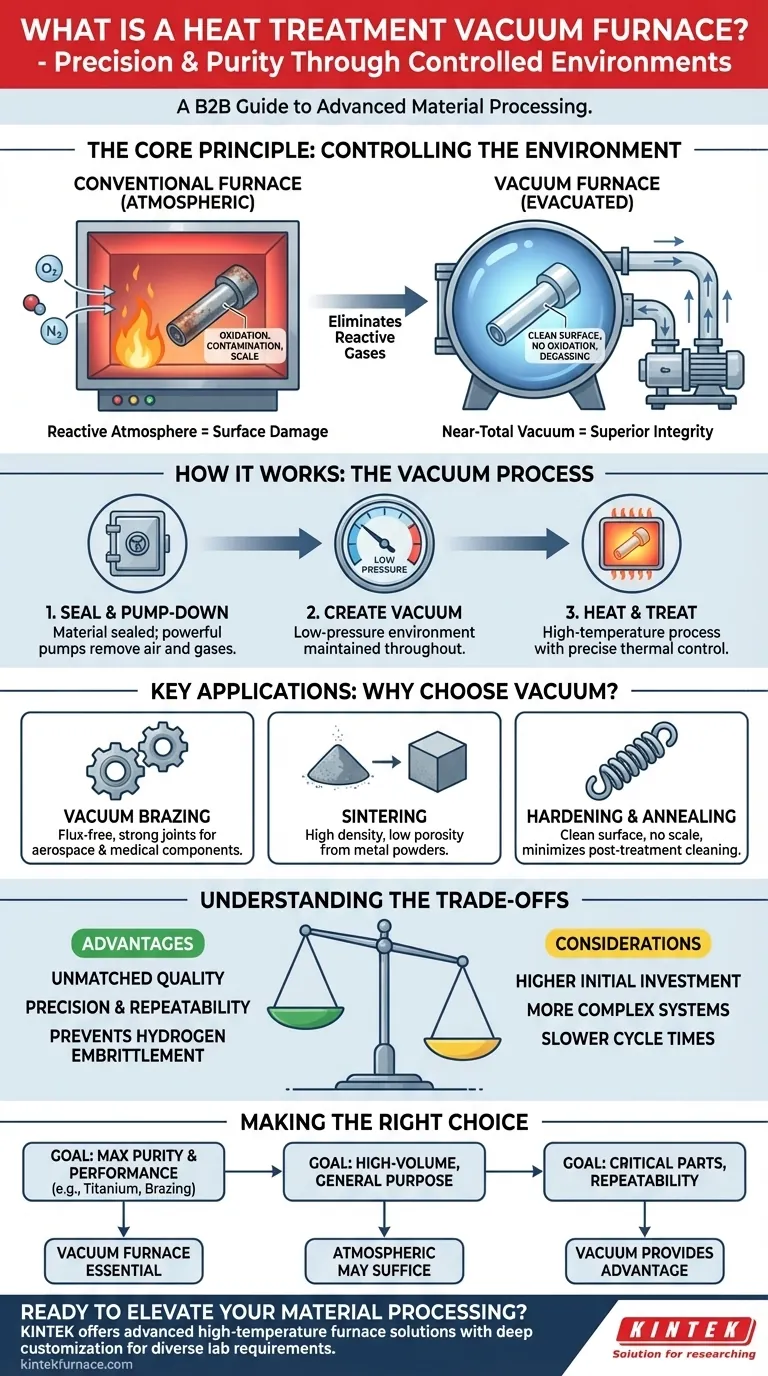

The Core Principle: Controlling the Environment

A traditional furnace heats materials in the presence of air, which is roughly 21% oxygen. At high temperatures, this oxygen readily reacts with the metal's surface. A vacuum furnace is designed to solve this fundamental problem.

How a Vacuum is Achieved

The process begins by sealing the material inside a chamber. A system of powerful vacuum pumps then removes the air and any other gases. This creates a low-pressure environment, or vacuum, that is maintained throughout the heating and cooling cycle.

Why Remove the Atmosphere?

The primary goal is to prevent contamination. Without oxygen, common negative effects like oxidation (rusting) and decarburization (loss of carbon from the steel's surface, which reduces hardness) are completely eliminated. This results in a bright, clean surface finish straight out of the furnace.

Furthermore, the vacuum environment can actually pull trapped gases like hydrogen and impurities out of the material itself in a process called degassing. This purifies the metal and improves its mechanical properties.

Key Applications and Processes

The unique environment of a vacuum furnace makes it ideal for processes where material purity and joint integrity are critical.

For High-Purity Joining: Vacuum Brazing

Brazing joins two pieces of metal using a filler material. In a vacuum, this process creates exceptionally strong, clean, and void-free joints without the need for corrosive chemical fluxes. This is essential for aerospace, medical, and electronics components.

For Advanced Material Forming: Sintering

Sintering is the process of fusing metal powders together using heat to form a solid component. Performing this in a vacuum prevents oxidation on the vast surface area of the powder particles, resulting in higher density and lower porosity in the final part.

For Enhancing Material Properties: Hardening, Annealing, & Tempering

These common heat treatments are used to adjust a material's hardness, ductility, and internal stresses. When done in a vacuum, the parts emerge with a clean surface, free from scale. This often eliminates the need for post-treatment cleaning or machining, saving time and cost.

Understanding the Trade-offs

While powerful, a vacuum furnace is a specialized tool with a distinct set of considerations compared to conventional atmospheric furnaces.

Unmatched Material Quality

The primary advantage is the superior metallurgical outcome. By preventing oxidation and decarburization, the material's surface remains pristine. This also prevents hydrogen embrittlement, a phenomenon where absorbed hydrogen can make high-strength steels brittle.

Precision and Repeatability

Vacuum furnaces offer high thermal efficiency, allowing for rapid heating and controlled cooling (quenching). This precise thermal control minimizes thermal stress and part distortion, leading to a highly repeatable and reliable process with high pass rates.

Higher Initial Investment and Complexity

Vacuum furnaces represent a significant capital investment compared to traditional furnaces. They are more complex systems requiring skilled operators and rigorous maintenance, particularly for ensuring the integrity of vacuum seals and pump systems.

Slower Cycle Times

Achieving and maintaining a deep vacuum takes time. The pump-down cycle adds to the overall process time, which can make vacuum furnaces less suitable for very high-volume, low-margin production where speed is the only priority.

Making the Right Choice for Your Goal

Deciding between a vacuum and an atmospheric furnace depends entirely on the metallurgical requirements of your component.

- If your primary focus is maximum material purity and performance: A vacuum furnace is essential for processes like brazing critical components or treating reactive metals like titanium.

- If your primary focus is high-volume, general-purpose heat treatment: A conventional atmospheric furnace may be more cost-effective for parts where a small amount of surface oxidation is acceptable or can be removed later.

- If your primary focus is process repeatability for critical parts: The precise control and clean environment of a vacuum furnace provide a significant advantage for minimizing distortion and ensuring consistent results.

Ultimately, choosing a vacuum furnace is an investment in achieving a level of material quality and process control that a conventional furnace simply cannot provide.

Summary Table:

| Aspect | Details |

|---|---|

| Core Principle | Uses high-temperature heating in a vacuum to prevent oxidation and contamination. |

| Key Processes | Vacuum brazing, sintering, hardening, annealing, and tempering. |

| Main Advantages | Superior material purity, elimination of decarburization, bright surface finish, and precise thermal control. |

| Trade-offs | Higher initial cost, slower cycle times, and requires skilled operation and maintenance. |

| Ideal Applications | Aerospace, medical, electronics, and any process needing high-purity, distortion-free results. |

Ready to elevate your material processing with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum furnaces can enhance your lab's efficiency and deliver superior results for your critical applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety