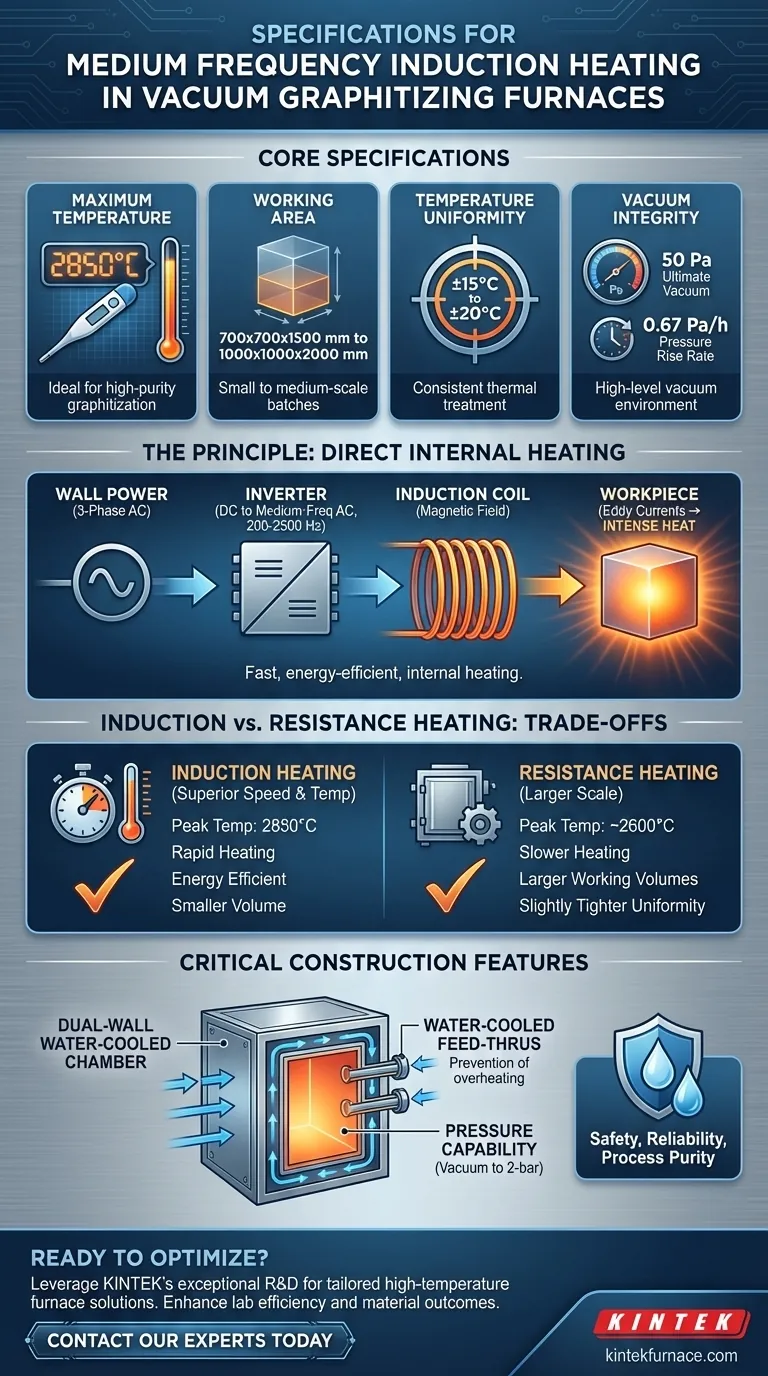

For a vacuum graphitizing furnace, the typical specifications for medium frequency induction heating include working area sizes ranging from 700x700x1500 mm to 1000x1000x2000 mm. These furnaces can achieve a maximum temperature of 2850°C with a temperature uniformity of ±15 to ±20°C. They operate with an ultimate vacuum of 50 Pa and a pressure rise rate of 0.67 Pa/h, indicating a high level of vacuum integrity.

Choosing the right heating technology is not just about hitting a target temperature. It's about understanding how the heating method itself impacts your process speed, batch size, and energy efficiency. Medium frequency induction offers unparalleled speed and temperature for specific applications, but this comes with trade-offs in scale compared to resistance heating.

Understanding the Core Specifications

To properly evaluate a furnace, you must understand what each specification means for your operational outcomes. These numbers define the furnace's performance envelope.

Maximum Temperature (2850°C)

This is the single most critical parameter for graphitization. The transformation of amorphous carbon into a crystalline graphite structure requires extremely high temperatures, and the 2850°C capability of induction systems is ideal for producing high-purity, high-performance graphitic materials.

Working Area (Up to 1000x1000x2000 mm)

This defines the maximum size or volume of material you can process in a single batch. The available sizes for induction heating are suited for small- to medium-scale production runs.

Temperature Uniformity (±15 to ±20°C)

This specification measures the temperature variation across the entire working area. A tighter uniformity ensures that all parts within a batch receive the same thermal treatment, leading to consistent material properties and predictable quality in the final product.

Vacuum Level and Integrity

The ultimate vacuum (50 Pa) defines the lowest pressure the furnace can achieve, which is crucial for preventing oxidation and removing volatile impurities at high temperatures. The pressure rise rate (0.67 Pa/h) measures how well the chamber holds this vacuum, indicating the quality of the seals and overall construction.

The Principle of Medium Frequency Induction Heating

Unlike conventional furnaces that heat from the outside in, induction heating generates heat directly within the material itself. This fundamental difference is the source of its primary advantages.

From Wall Power to Induced Heat

The furnace converts standard three-phase AC power into DC. An inverter then changes this DC back into a high-current, medium-frequency AC (typically 200-2500 Hz). This current is fed into a copper induction coil inside the furnace.

The Role of Eddy Currents

The alternating current in the coil generates a powerful and rapidly changing magnetic field. This magnetic field penetrates the electrically conductive material to be heated (such as a graphite crucible or the carbon precursor itself), inducing powerful electrical currents within it, known as eddy currents.

Direct, Efficient Heating

As these eddy currents flow through the material against its natural electrical resistance, they generate intense heat. Because the heat is created inside the workpiece, the heating process is exceptionally fast and energy-efficient, with less wasted energy heating the entire furnace chamber.

Understanding the Trade-offs: Induction vs. Resistance Heating

Many graphitizing furnaces can be configured with either induction or resistance heating. Understanding their differences is key to making an informed decision.

Temperature and Speed

Induction heating is the clear winner for peak temperature and speed, reaching 2850°C rapidly. Resistance heating typically tops out at a lower temperature (around 2600°C) and requires a significantly longer time to reach its target temperature.

Scale and Working Volume

This is the primary advantage of resistance heating. Resistance furnaces are available with much larger working volumes (e.g., 2000x2000x4000 mm), making them suitable for very large components or high-volume batch production that would be impractical in an induction furnace.

Energy Efficiency

Induction heating is generally more energy-efficient. By generating heat directly where it's needed, it minimizes thermal loss to the furnace walls and insulation. Resistance furnaces heat the entire hot zone via radiation from heating elements, resulting in higher ambient energy loss.

Temperature Uniformity

Both technologies offer good uniformity. However, resistance heating systems can sometimes achieve a slightly tighter tolerance (e.g., ±10°C) over a very large volume due to the radiant nature of the heat transfer.

Critical Construction and Operational Features

The extreme conditions inside a graphitizing furnace demand robust engineering to ensure safety, reliability, and process purity.

Dual-Wall Water-Cooled Chamber

The furnace chamber and door are built with a dual-wall stainless steel design. Water circulates continuously between these walls to manage the immense heat load, protecting the structural integrity of the furnace and keeping the external surfaces cool and safe.

Preventing Contamination

To maintain a pure vacuum environment, power feed-thrus and other access points are also water-cooled. This prevents overheating and potential water leakage into the hot zone, which is critical for avoiding contamination of the product.

Pressure Capability

These furnaces are designed to operate from a full vacuum up to a positive pressure of 2-bar (or more). This flexibility allows for different process steps, such as running a cycle under a specific inert gas atmosphere after the initial vacuum purge.

Making the Right Choice for Your Graphitization Process

Your choice between medium frequency induction and other heating methods depends entirely on your specific process requirements and business goals.

- If your primary focus is achieving the highest graphitization temperatures and rapid cycle times for advanced materials: Medium frequency induction is the superior choice.

- If your primary focus is processing very large batches or components where production volume is the main constraint: Resistance heating offers significantly larger working zones.

- If your primary focus is maximizing energy efficiency for lower operational costs: Induction heating's direct heating method provides a distinct advantage.

By understanding these core principles and trade-offs, you can confidently select the heating technology that aligns precisely with your material and production goals.

Summary Table:

| Specification | Typical Range for Medium Frequency Induction |

|---|---|

| Maximum Temperature | 2850°C |

| Working Area (LxWxH) | 700x700x1500 mm to 1000x1000x2000 mm |

| Temperature Uniformity | ±15°C to ±20°C |

| Ultimate Vacuum | 50 Pa |

| Pressure Rise Rate | 0.67 Pa/h |

| Heating Method | Direct, internal heating via eddy currents |

| Primary Advantage | High temperature, rapid heating, energy efficiency |

| Trade-off | Smaller working volume compared to resistance furnaces |

Ready to Optimize Your Graphitization Process?

Your choice of heating technology directly impacts your product quality, throughput, and operational costs. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs.

- For high-purity, high-performance graphitic materials requiring rapid cycle times and temperatures up to 2850°C, our Medium Frequency Induction Furnaces are the ideal solution.

- Need a different scale or process? Our diverse product line, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities.

Let's discuss your specific requirements. Contact our experts today to explore how a KINTEK furnace can enhance your lab's efficiency and material outcomes.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability