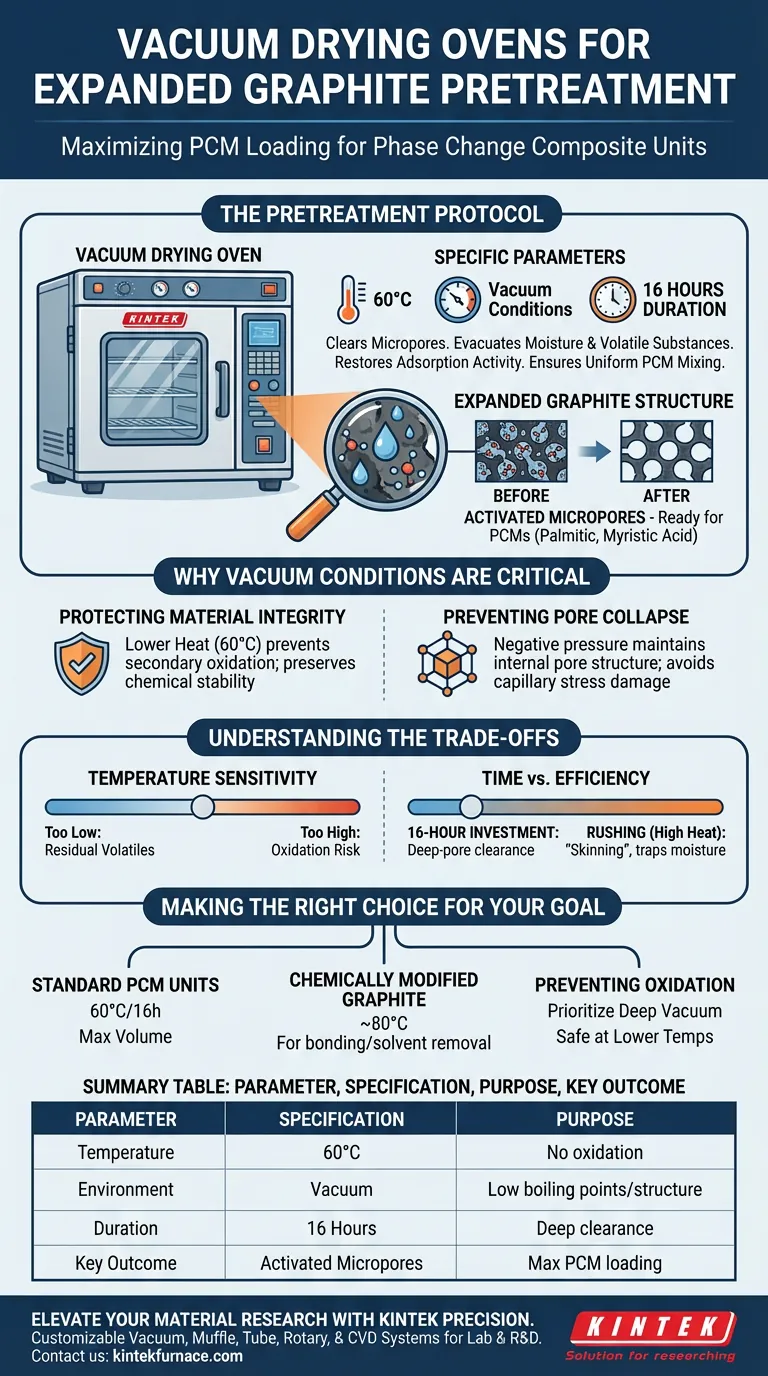

In the context of preparing phase change composite units, the vacuum drying oven serves as a critical surface activation step for expanded graphite. Specifically, the material is subjected to a temperature of 60°C under vacuum conditions for a duration of 16 hours.

This precise thermal treatment thoroughly evacuates moisture and volatile substances trapped within the graphite’s micropores. By clearing these internal voids, the process restores the expanded graphite's adsorption activity, ensuring it can uniformly absorb and hold phase change materials (PCMs) such as palmitic acid and myristic acid.

The vacuum drying process acts as a structural "reset" for the expanded graphite. By lowering the evaporation point of trapped impurities, it clears the material's microporous network without subjecting it to damaging high temperatures, thereby maximizing the available volume for energy-storing phase change materials.

The Pretreatment Protocol

The Specific Parameters

To achieve the optimal state for composite formation, the expanded graphite must be dried at 60°C for 16 hours.

This moderate temperature is sufficient because the vacuum environment significantly lowers the boiling point of water and volatile organics.

Clearing the Micropores

The primary physical goal is the removal of moisture and volatile substances.

Expanded graphite is highly porous, acting like a microscopic sponge. Without this drying step, water molecules occupy the micropores, physically blocking the entry of the phase change material.

Ensuring Uniform Mixing

The ultimate objective of this pretreatment is to facilitate uniform mixing.

When the pores are completely dry and empty, the expanded graphite exhibits peak adsorption activity. This allows the subsequent phase change materials (palmitic or myristic acid) to penetrate deep into the structure rather than just coating the surface.

Why Vacuum Conditions Are Critical

Protecting Material Integrity

Drying at atmospheric pressure would typically require higher temperatures to achieve the same level of moisture removal.

High heat can risk secondary oxidation of the graphite surface. By using a vacuum, you achieve rapid evaporation at only 60°C, preserving the chemical stability and structural integrity of the graphite.

Preventing Pore Collapse

The negative pressure environment aids in maintaining the internal pore structure.

Rapid evaporation at high heat can sometimes cause capillary stresses that damage fragile pore walls. Vacuum drying creates a gentler environment that keeps the "skeleton" of the expanded graphite intact for maximum loading capacity.

Understanding the Trade-offs

Temperature Sensitivity

While 60°C is ideal for standard expanded graphite pretreatment, it is a specific calibration.

If the temperature is too low, residual volatiles may remain, reducing the composite's energy storage density. If the temperature is too high (e.g., approaching 100°C+ without specific modifiers), you risk oxidizing the carbon lattice, which degrades thermal conductivity.

Time vs. Efficiency

The 16-hour duration is a significant time investment in the manufacturing process.

Attempts to rush this process by increasing heat to reduce time can lead to "skinning" or surface closure, where the outer layer dries and seals off the inner pores, trapping moisture inside. The long, low-temp vacuum cycle is non-negotiable for deep-pore clearance.

Making the Right Choice for Your Goal

The specific settings of your vacuum drying process should be dictated by the chemical composition of your graphite and the intended phase change material.

- If your primary focus is standard Phase Change Composite Units: Adhere strictly to the 60°C / 16-hour protocol to maximize micropore volume for fatty acids like palmitic or myristic acid.

- If your primary focus is Chemically Modified Graphite (e.g., with Silanes): You may need to increase the temperature to roughly 80°C, as this promotes chemical bonding between modifiers and the graphite surface while removing solvents like ethanol.

- If your primary focus is preventing Oxidation: Prioritize the quality of the vacuum seal over temperature; a deep vacuum allows you to dry effectively at lower temperatures, safeguarding the material against oxygen exposure.

The success of your composite relies not just on the quality of the graphite, but on the emptiness of its pores prior to loading.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Temperature | 60°C | Removes volatiles without risking graphite oxidation |

| Environment | Vacuum | Lowers boiling points & prevents pore wall collapse |

| Duration | 16 Hours | Ensures deep-pore clearance and moisture removal |

| Key Outcome | Activated Micropores | Maximizes loading capacity for PCMs like palmitic acid |

Elevate Your Material Research with KINTEK Precision

Maximize the storage density and thermal performance of your phase change composites with high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet your specific temperature and vacuum requirements.

Whether you are performing sensitive surface activation or complex chemical vapor deposition, our equipment provides the stability and control your research demands. Contact us today to find the perfect thermal solution for your lab!

Visual Guide

References

- Zhiwei Huang, Yan Zhang. Mechanical structure design and performance analysis of heat storage working medium for heat insulation layer. DOI: 10.2298/tsci2402271h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the electronics and semiconductor applications of furnace brazing? Achieve Reliable, High-Performance Component Joining

- How does a high-temperature austenitization furnace ensure structural transformation? Mastering Fe-5%Mn-C Quenching

- How does a vacuum system facilitate antimony-tellurium alloy distillation? Maximize Purity with Low-Temp Separation

- What is the application of vacuum furnaces in ceramics sintering? Achieve High-Purity, Dense Ceramics

- What are the benefits of the degassing effect during vacuum heating? Unlock Superior Metal Performance and Durability

- What temperature is vacuum brazing? Achieve Strong, Flux-Free Joints in a Controlled Environment

- How does a high vacuum annealing furnace contribute to 2D Bi2Te3-Sb2Te3 superlattices? Precision Thermal Engineering

- How does vacuum sintering help in material purification? Achieve Superior Purity and Performance