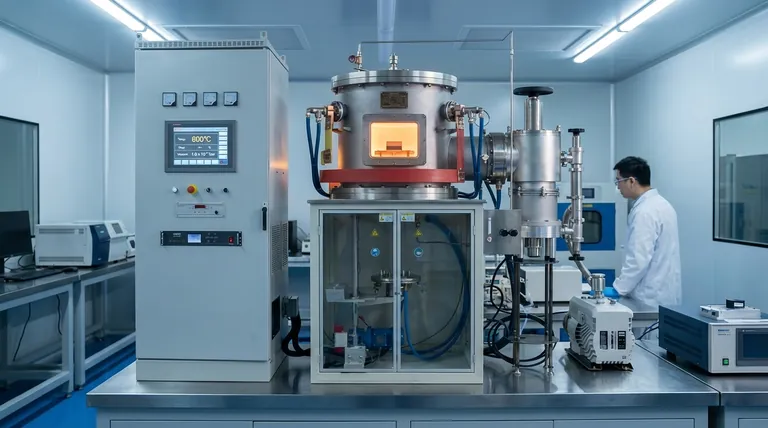

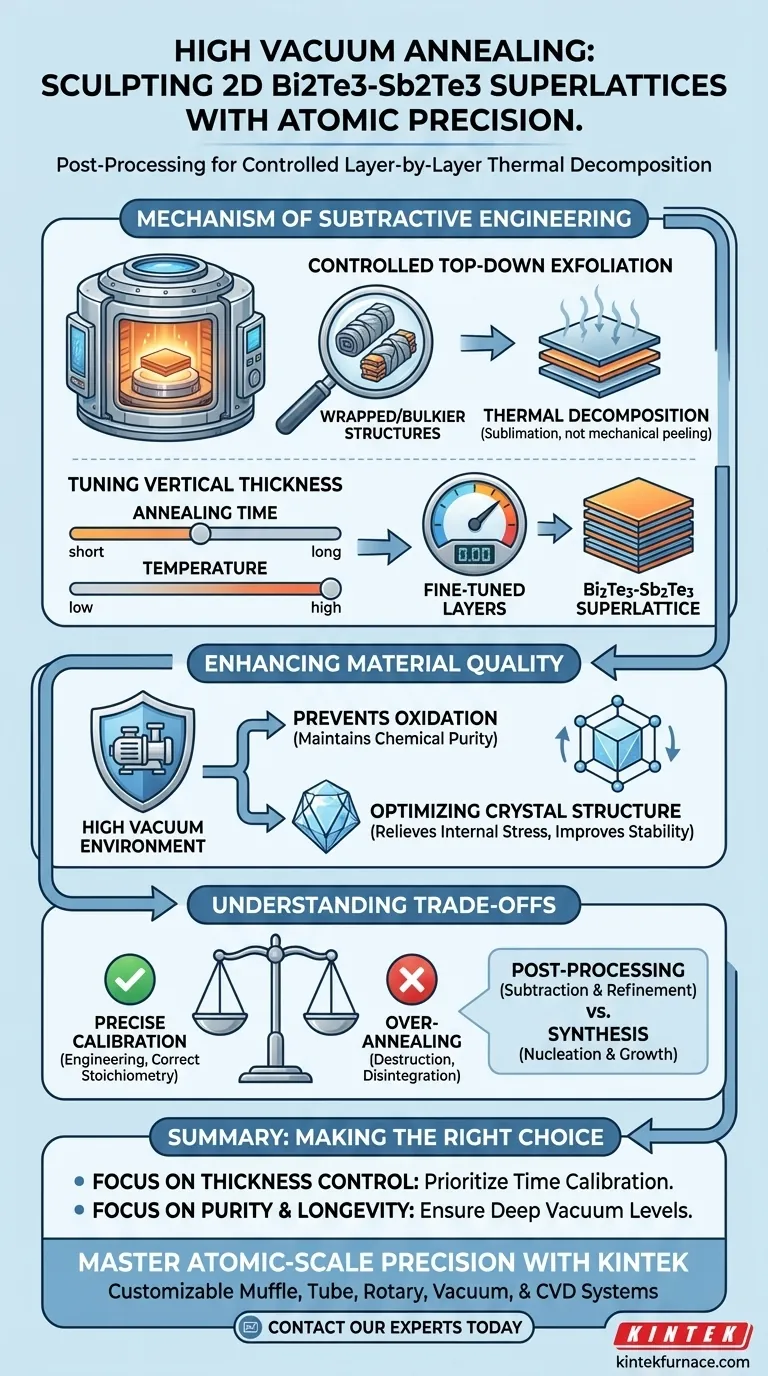

A high vacuum annealing furnace functions as a precision sculpting tool for 2D Bi2Te3-Sb2Te3 superlattices, facilitating a process known as controlled layer-by-layer thermal decomposition. Unlike synthesis equipment which builds material, this post-processing technique acts as a "top-down" exfoliation method. By strictly regulating the annealing time and temperature within a vacuum, engineers can fine-tune the vertical thickness of the material, effectively converting wrapped or bulkier structures into superlattices with a specific, desired number of layers.

While chemical vapor deposition (CVD) creates the initial material, high vacuum annealing defines its final geometry. This process leverages thermal decomposition to subtract layers with atomic precision, allowing for exact control over the superlattice's thickness and structural configuration.

The Mechanism of Subtractive Engineering

Controlled Top-Down Exfoliation

The primary contribution of the high vacuum annealing furnace is its ability to induce thermal decomposition.

Rather than mechanically peeling layers, the furnace uses heat to sublimate the material layer by layer. This transforms the furnace into a tool for top-down exfoliation, allowing engineers to reduce the material from a thicker state to a thinner, more precise configuration.

Tuning Vertical Thickness

The utility of this process lies in its tunability.

By adjusting two key variables—annealing time and temperature—you can dictate exactly how much material is removed. This capability is essential for defining the vertical thickness of the superlattice, ensuring it meets the stringent dimensional requirements of 2D engineering.

Geometric Conversion

Annealing is not just about thinning; it is about structural correction.

The process is specifically noted for its ability to convert wrapped structures into proper superlattices. This morphological change ensures that the final product maintains the correct layered architecture required for its electronic or thermal applications.

Enhancing Material Quality

Preventing Oxidation

Beyond dimension control, the "high vacuum" aspect of the furnace is critical for chemical stability.

Operating in a high vacuum environment prevents oxidation reactions that would otherwise degrade the sensitive Bi2Te3-Sb2Te3 layers at high temperatures. This ensures that while the material is being physically thinned, its chemical purity is strictly maintained.

Optimizing Crystal Structure

Post-processing annealing is also vital for structural relaxation.

The process helps eliminate internal residual stresses accumulated during the initial growth phase. This thermal treatment improves the material's plasticity and toughness, optimizing the grain structure to enhance overall hardness and stability.

Understanding the Trade-offs

Decomposition vs. Destruction

The line between engineering and destruction in this process is thin.

Because the mechanism relies on decomposition, there is a risk of over-annealing, which can disintegrate the superlattice entirely or disrupt the stoichiometry of the Bi2Te3-Sb2Te3 layers. Precise calibration of the thermal window is non-negotiable.

Post-Processing vs. Synthesis

It is crucial to distinguish this equipment from the multi-zone tube furnaces used in CVD synthesis.

While CVD furnaces focus on the nucleation and epitaxial growth of precursor molecules using carrier gases, the high vacuum annealing furnace focuses on subtraction and refinement. Attempting to use a growth-oriented furnace setup for this specific decomposition task without high-vacuum controls may lead to contamination or uncontrolled sublimation.

Making the Right Choice for Your Goal

To maximize the effectiveness of high vacuum annealing for your specific application, consider the following:

- If your primary focus is precise thickness control: Prioritize the calibration of annealing time over temperature, as time provides a more linear control variable for layer-by-layer removal.

- If your primary focus is material purity and longevity: Ensure your vacuum system is capable of maintaining deep vacuum levels throughout the heating cycle to absolutely negate oxidation risks during the decomposition phase.

Mastering the high vacuum annealing process allows you to transition from simply growing materials to precisely engineering their atomic-scale architecture.

Summary Table:

| Feature | Contribution to Superlattice Engineering |

|---|---|

| Mechanism | Controlled top-down thermal decomposition and exfoliation |

| Thickness Control | Fine-tuning vertical layers via precise time/temperature variables |

| Morphology | Converts wrapped or bulk structures into uniform superlattices |

| Chemical Purity | High vacuum environment prevents oxidation during processing |

| Structural Quality | Relieves internal stresses and optimizes grain structure |

Master Atomic-Scale Precision with KINTEK

Take control of your material geometry with our specialized thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique 2D material engineering needs. Whether you are performing delicate top-down exfoliation or complex epitaxial growth, our equipment provides the stability and vacuum integrity your research demands.

Ready to refine your superlattice architecture? Contact our experts today to discover how KINTEK can enhance your lab's efficiency and precision.

Visual Guide

References

- Han Wang, Wen Lei. Superlattice Engineering on 2D Bi<sub>2</sub>Te<sub>3</sub>‐Sb<sub>2</sub>Te<sub>3</sub> Chalcogenides. DOI: 10.1002/advs.202503492

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum and atmosphere control system necessary for SiC sintering? Prevent Oxidation and Ensure High Purity

- Why is a vacuum drying oven required for lithium-sulfur battery electrodes? Ensure High-Purity Testing Results

- What role do high-temperature vacuum furnaces play in CVD and PVD processes? Essential for Purity and Precision in Thin-Film Deposition

- What types of materials are processed using vacuum resistance furnaces? Ideal for Reactive Metals, Alloys, and Ceramics

- How does a vacuum high-temperature impregnation furnace facilitate the densification of Si-SiC materials? LSI Explained

- What physical conditions do laboratory thermal cycling systems provide for hydride reorientation in zirconium alloys?

- What is the significance of vacuum degree in vacuum sintering furnaces? Optimize Material Purity and Performance

- What role does high vacuum heating equipment play in copper-boron wetting? Achieve 10^-6 mbar Precision