At its core, a vacuum resistance furnace is designed to process materials that cannot tolerate exposure to atmospheric gases at high temperatures. These primarily include highly reactive metals like titanium, zirconium, and tungsten, advanced ceramics, and specific steel alloys requiring a pristine, oxide-free surface finish after heat treatment.

The decision to use a vacuum furnace is not about the material itself, but about the desired outcome. It is the definitive tool for preventing unwanted chemical reactions—chiefly oxidation—to achieve exceptional purity, strength, or surface quality in the final product.

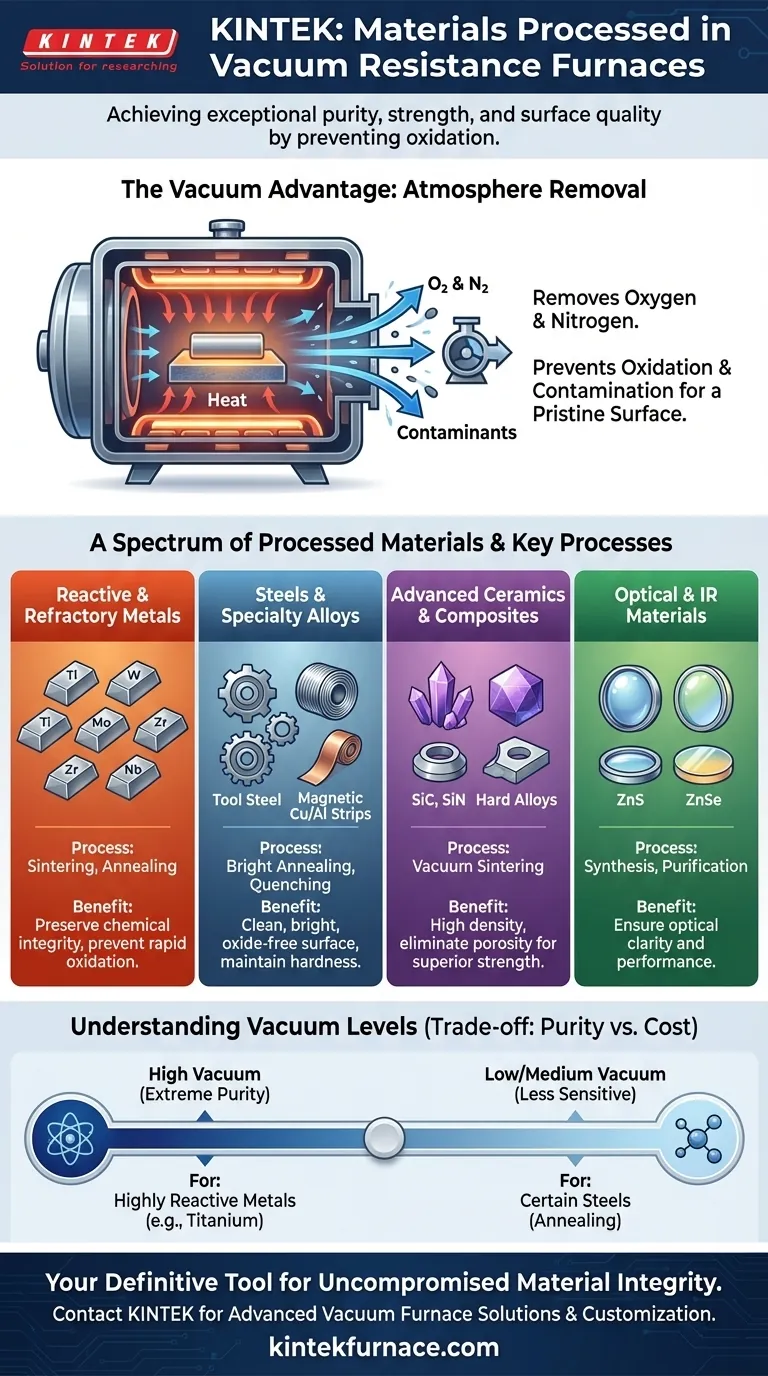

Why a Vacuum Environment is Critical

The function of the vacuum is to remove the atmosphere, primarily oxygen and nitrogen, that would otherwise react with the material being heated. This control over the processing environment is the furnace's primary advantage.

Preventing Oxidation and Contamination

At elevated temperatures, most metals and many advanced materials become highly reactive. Exposure to even small amounts of oxygen can form an undesirable oxide layer on the surface.

For active and refractory metals like titanium, tungsten, and molybdenum, this reaction is rapid and detrimental to the material's properties. A vacuum removes the reactants, preserving the material's chemical integrity.

Ensuring High Purity and Density

A vacuum environment is inherently clean. By removing atmospheric gases, it prevents the introduction of impurities that could compromise the final product.

This is especially critical for vacuum sintering, a process used to create high-density parts from powders. Removing trapped gases from the material allows the particles to bond more effectively, resulting in a stronger, denser final product for materials like high-strength ceramics and hard alloys.

Achieving a "Bright" Surface Finish

Processes like bright annealing and bright quenching are named for the result they produce: a clean, shiny, oxide-free surface.

This is essential for components like high-speed tool steel, die steel, and copper strips, where a surface oxide scale would interfere with performance or subsequent manufacturing steps. The vacuum prevents this scale from ever forming.

A Spectrum of Processed Materials

The need for a controlled atmosphere applies to a surprisingly diverse range of materials, each with a specific process goal.

Reactive and Refractory Metals

This is the classic application for vacuum furnaces. These metals are prized for their unique properties but are easily oxidized at high temperatures.

- Titanium (Ti)

- Zirconium (Zr)

- Tungsten (W)

- Molybdenum (Mo)

- Niobium (Nb)

Steels and Specialty Alloys

For many alloys, the goal is precise heat treatment without surface degradation.

- High-speed tool steel & die steel: Require bright quenching to maintain hardness and a clean surface.

- Soft magnetic alloys & electrical pure iron: Need bright annealing to achieve specific magnetic properties without introducing impurities.

- Aluminum foil & copper tube strips: Processed to be free of surface oxides.

Advanced Ceramics and Composites

These materials are often synthesized or sintered in a vacuum to achieve maximum density and strength.

- Silicon carbide (SiC)

- Silicon nitride (SiN)

- Hard alloys (cermets)

- Metal/ceramic composites

Optical and Infrared Materials

The production of high-purity specialty compounds often requires a vacuum to ensure optical clarity and performance.

- Zinc sulfide (ZnS)

- Zinc selenide (ZnSe)

Understanding the Trade-offs: Vacuum Level Matters

Not all vacuum processes are identical. The sensitivity of the material dictates the level of vacuum required, which presents a trade-off between cost and performance.

High Vacuum for Extreme Purity

Highly reactive materials like titanium or high-purity molybdenum demand a high vacuum. This deep vacuum level removes the maximum number of atmospheric molecules, leaving an ultra-pure environment for processing.

Low Vacuum for Less Sensitive Materials

For less sensitive applications, such as annealing certain steels, a low or medium vacuum may be sufficient. This level of vacuum is adequate to prevent the worst of the oxidation while being more cost-effective to achieve and maintain.

Making the Right Choice for Your Goal

The material you are processing is directly linked to the properties you need to protect or create. Use your end goal to guide your approach.

- If your primary focus is processing highly reactive metals (like titanium or tungsten): A high-vacuum furnace is non-negotiable to prevent catastrophic oxidation and ensure material integrity.

- If your primary focus is heat treating steels for a clean finish: A vacuum furnace capable of bright annealing or quenching is essential to avoid costly and damaging oxide scale formation.

- If your primary focus is producing high-density ceramics or hard alloys: Vacuum sintering is the required process to eliminate porosity and achieve superior mechanical properties.

Ultimately, a vacuum resistance furnace is the definitive tool when the integrity of your material at high temperatures cannot be compromised.

Summary Table:

| Material Category | Examples | Key Processes |

|---|---|---|

| Reactive and Refractory Metals | Titanium, Zirconium, Tungsten | Sintering, Annealing |

| Steels and Specialty Alloys | High-speed tool steel, Soft magnetic alloys | Bright Annealing, Quenching |

| Advanced Ceramics and Composites | Silicon carbide, Hard alloys | Vacuum Sintering |

| Optical and Infrared Materials | Zinc sulfide, Zinc selenide | Synthesis, Purification |

Ready to achieve superior purity and performance in your high-temperature processes? KINTEK specializes in advanced vacuum resistance furnaces tailored for reactive metals, alloys, and ceramics. With our exceptional R&D and in-house manufacturing, we offer a product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization to meet your unique experimental needs. Contact us today to discuss how our solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance