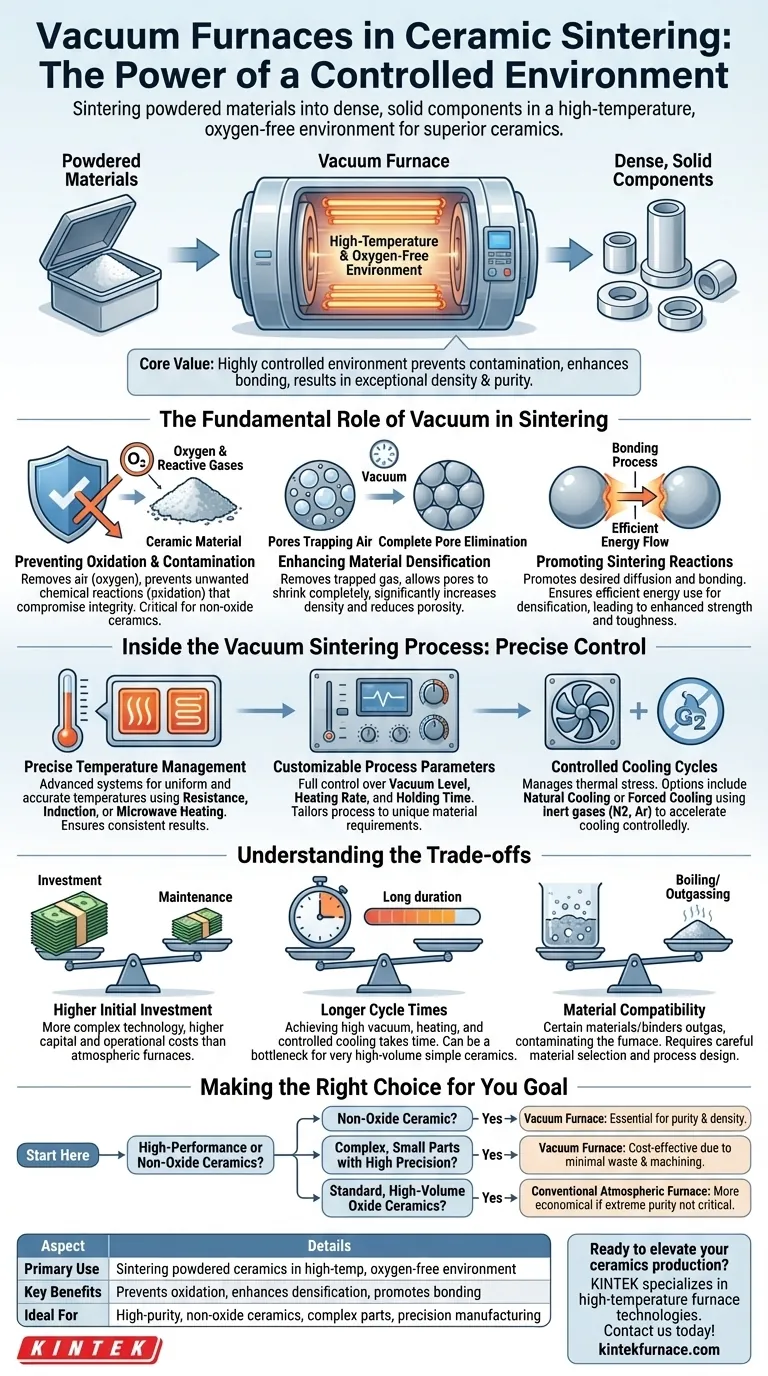

In ceramics manufacturing, vacuum furnaces are used to sinter powdered materials into dense, solid components in a high-temperature, oxygen-free environment. This process is critical for producing high-purity, high-performance ceramics with superior mechanical properties like hardness and strength that are difficult to achieve in conventional atmospheric furnaces.

The core value of a vacuum furnace is not just the heat it provides, but the highly controlled environment it creates. By removing reactive gases like oxygen, it prevents contamination and allows ceramic particles to bond more effectively, resulting in a final product with exceptional density and purity.

The Fundamental Role of Vacuum in Sintering

To understand the application of vacuum furnaces, you must first understand why the environment is as important as the temperature. Sintering in a vacuum fundamentally alters the process at a molecular level.

Preventing Oxidation and Contamination

The primary function of the vacuum is to remove air, specifically oxygen and other reactive gases. This prevents unwanted chemical reactions, such as oxidation, that can compromise the integrity and purity of the ceramic material.

This is especially critical for non-oxide ceramics or materials that are highly sensitive to atmospheric contaminants.

Enhancing Material Densification

During sintering, particles fuse together, and the spaces between them (pores) shrink. In a conventional furnace, air can become trapped within these pores, inhibiting the material's ability to become fully dense.

A vacuum environment removes this trapped gas, allowing for more complete pore elimination and leading to a component with significantly higher density and lower porosity.

Promoting Sintering Reactions

The clean, controlled environment of a vacuum furnace promotes the desired diffusion and bonding processes between ceramic particles. This ensures that the energy from the heat is used efficiently for densification rather than for unwanted side reactions, resulting in enhanced strength and toughness.

Inside the Vacuum Sintering Process

Modern vacuum furnaces offer a high degree of control over every stage of the sintering cycle, enabling the production of precisely engineered components.

Precise Temperature Management

Advanced temperature control systems are standard. These furnaces use various heating methods, including resistance heating, induction heating, or even microwave heating, to achieve uniform and accurate temperatures required for specific ceramic formulations.

This precision ensures consistent results from batch to batch.

Customizable Process Parameters

Operators have full control over the key process variables. The vacuum level, heating rate, and holding time can all be adjusted to create a personalized sintering process tailored to the unique requirements of the material being processed.

Controlled Cooling Cycles

The cooling phase is just as critical as the heating phase for managing thermal stress and achieving the desired final microstructure.

Furnaces offer options from natural cooling to forced cooling, which often uses an inert gas like high-purity nitrogen or argon to accelerate the process in a controlled manner.

Understanding the Trade-offs

While powerful, vacuum sintering is not the default choice for every application. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces are technologically complex and represent a significantly higher capital investment compared to standard atmospheric furnaces. Their operational and maintenance costs can also be higher.

Longer Cycle Times

Achieving a high vacuum, running the heating profile, and executing a controlled cooling cycle can be a time-consuming process. For very high-volume production of simple ceramics, this can be a bottleneck.

Material Compatibility

Certain ceramic materials or binders can have a high vapor pressure, meaning they tend to "boil" or outgas under vacuum at high temperatures. This can contaminate the furnace and disrupt the sintering process, requiring careful material selection and process design.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace depends entirely on the required properties of the final component and the nature of the material.

- If your primary focus is producing high-performance or non-oxide ceramics: A vacuum furnace is essential for preventing contamination and achieving the required purity and density.

- If your primary focus is manufacturing complex, small parts with high precision: Vacuum sintering can be highly cost-effective by minimizing material waste and eliminating the need for secondary machining.

- If your primary focus is standard, high-volume oxide ceramics: A conventional atmospheric furnace is often more economical if extreme purity and density are not critical design requirements.

Ultimately, choosing a vacuum furnace is an investment in process control, enabling the creation of ceramic materials with precisely engineered properties.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | Sintering powdered ceramics in a high-temperature, oxygen-free environment |

| Key Benefits | Prevents oxidation, enhances densification, promotes bonding for superior mechanical properties |

| Process Control | Adjustable vacuum levels, heating rates, holding times, and cooling cycles |

| Ideal For | High-purity, non-oxide ceramics, complex parts, and precision manufacturing |

| Limitations | Higher cost, longer cycle times, and material compatibility considerations |

Ready to elevate your ceramics production with advanced sintering solutions? KINTEK specializes in high-temperature furnace technologies, including vacuum and atmosphere furnaces, tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Contact us today to discuss how our products can enhance your material performance and efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing