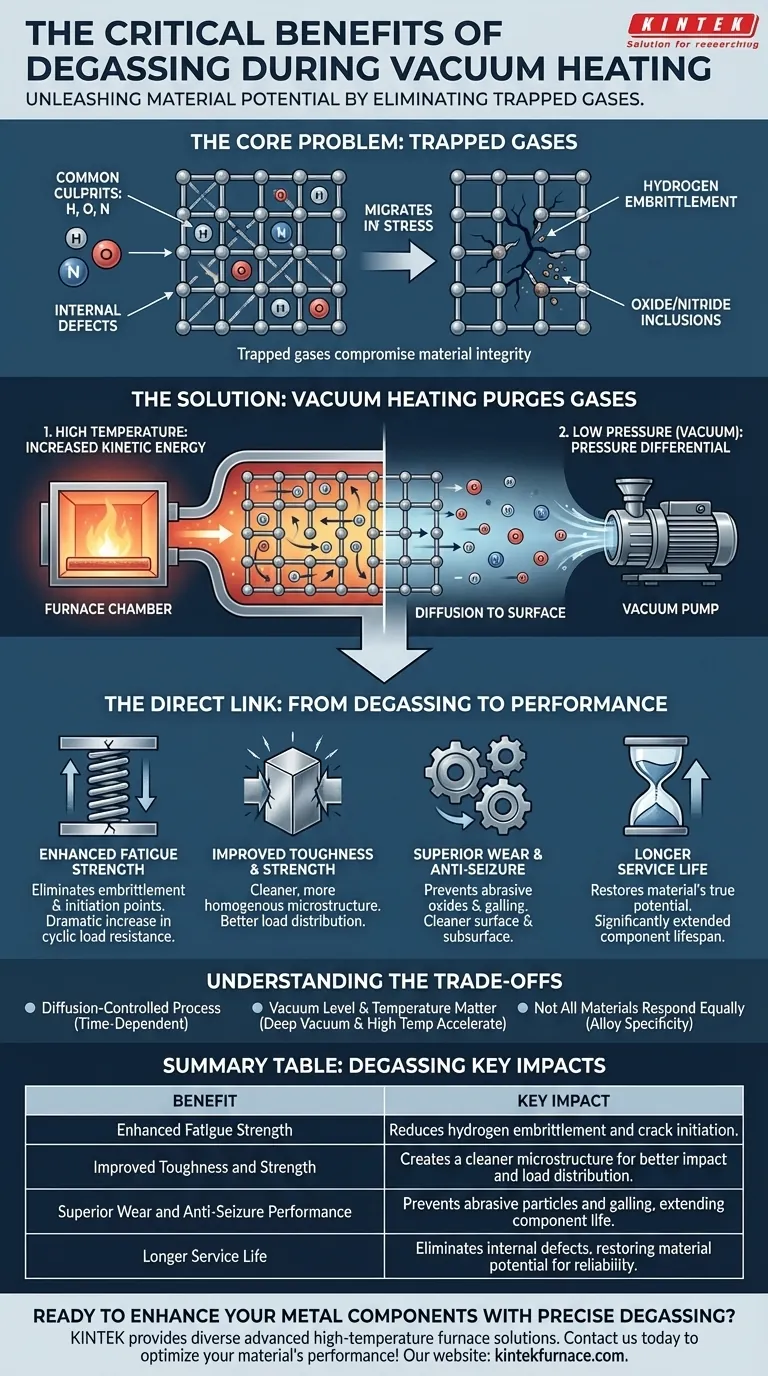

In short, the degassing effect during vacuum heating is a critical metallurgical benefit that directly improves a material's mechanical properties. By removing trapped gases, the process enhances strength, wear resistance, anti-seizure performance, and fatigue strength, which results in a significantly longer service life for the finished component.

While the list of benefits is clear, the fundamental question is how removing microscopic amounts of gas can so drastically improve a metal's performance. The answer lies in eliminating internal sources of embrittlement and weakness at an atomic level, creating a cleaner and more structurally sound material.

The Core Problem: Trapped Gases in Metals

Before a component even enters a furnace, the raw material contains dissolved gases. These are unavoidable byproducts of the initial melting, casting, and forming processes.

The Common Culprits: H, O, N

The three primary gases of concern dissolved in steel and other alloys are hydrogen (H), oxygen (O), and nitrogen (N).

Hydrogen is the most insidious, as its tiny atoms can easily diffuse through the metal's crystal structure. Oxygen and nitrogen tend to bond with the metal or other elements, forming internal impurities.

How Trapped Gases Weaken Metal

These dissolved gases are not benign. They are internal defects that compromise the material's integrity.

The most significant issue is hydrogen embrittlement. Under stress, hydrogen atoms migrate to areas of high tension, like the tip of a microscopic crack, and build up internal pressure. This severely reduces the metal's ductility, making it brittle and prone to sudden, catastrophic failure well below its expected strength.

Oxygen and nitrogen form hard, brittle particles like oxides and nitrides. These act as internal stress risers, providing perfect initiation sites for fatigue cracks to form and grow.

How Vacuum Heating Purges Trapped Gases

Vacuum heat treatment creates the ideal environment to force these harmful gases out of the material through a process of diffusion. The process relies on two key principles.

The Role of High Temperature

Heating the material gives the trapped gas atoms more kinetic energy. This increased energy allows them to move, or diffuse, much more freely within the metal's solid crystal lattice.

The Role of Low Pressure (Vacuum)

The vacuum pump removes the atmosphere from the furnace, creating a massive pressure differential. The partial pressure of hydrogen, oxygen, and nitrogen inside the metal is suddenly far higher than the pressure in the surrounding chamber.

Driven by this gradient, the newly mobile gas atoms diffuse from the interior of the component to its surface, where they are pulled away by the vacuum system.

The Direct Link: From Degassing to Performance

By removing these internal sources of failure, the material's inherent properties can shine through. The improvement is not additive; it's a restoration of the material's true potential.

Enhanced Fatigue Strength

By removing hydrogen, the primary cause of embrittlement is eliminated. By removing oxide and nitride inclusions, the internal initiation points for fatigue cracks are removed. The result is a dramatic increase in the material's ability to withstand cyclic loading.

Improved Toughness and Strength

A cleaner, more homogenous microstructure free from brittle particles is inherently tougher and stronger. The energy from an impact or load is distributed more evenly across the metallic structure, rather than concentrating at a defect.

Superior Wear and Anti-Seizure Performance

The removal of gases results in a cleaner surface and subsurface. This prevents hard oxide particles from becoming dislodged and acting as an abrasive third body, which improves both wear and the material's resistance to galling or seizure under high-pressure contact.

Understanding the Trade-offs

While highly effective, the degassing effect is governed by physical laws and is not an instantaneous magic bullet.

It Is a Diffusion-Controlled Process

Degassing takes time. Gases must migrate from the core of the part to the surface. Thicker components require significantly longer hold times at temperature to allow for full diffusion, which increases cycle time and cost.

Vacuum Level and Temperature Matter

A deeper vacuum and higher temperature will accelerate the degassing process. However, there are practical limits. The temperature must be appropriate for the specific alloy's heat treatment, and achieving an extremely high vacuum comes with rapidly diminishing returns and higher equipment costs.

Not All Materials Respond Equally

Some alloys are more susceptible to gas absorption during their creation than others. The necessity and parameters of a degassing cycle must be evaluated based on the specific material and its intended application, particularly for mission-critical components.

Making the Right Choice for Your Goal

Understanding the mechanism of degassing allows you to apply vacuum heat treatment strategically to achieve specific engineering outcomes.

- If your primary focus is fatigue life (e.g., springs, bearings, aerospace structures): Prioritize a robust vacuum cycle to mitigate hydrogen embrittlement, as this is the leading cause of premature failure in high-cycle applications.

- If your primary focus is toughness and impact resistance (e.g., high-performance tooling, dies): Leverage degassing to create a clean microstructure free of the oxide inclusions that act as initiation points for brittle fracture.

- If your primary focus is optimizing surface performance (e.g., gears, wear components): Use the degassing effect to ensure a clean surface and subsurface, enhancing wear resistance and reducing the risk of galling.

By treating degassing as a deliberate engineering tool, you move beyond simply heating a part and begin to refine its very structure for maximum performance and reliability.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Enhanced Fatigue Strength | Reduces hydrogen embrittlement and crack initiation, improving cyclic load resistance |

| Improved Toughness and Strength | Creates a cleaner microstructure for better impact and load distribution |

| Superior Wear and Anti-Seizure Performance | Prevents abrasive particles and galling, extending component life |

| Longer Service Life | Eliminates internal defects, restoring material potential for reliability |

Ready to enhance your metal components with precise degassing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum heating solutions can optimize your material's performance and durability!

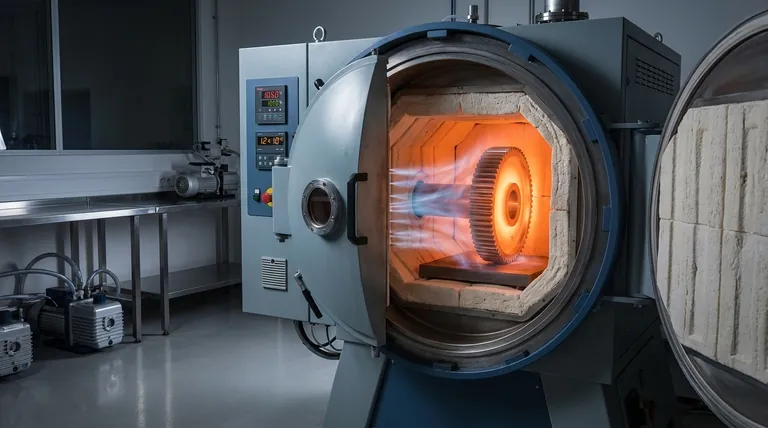

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance