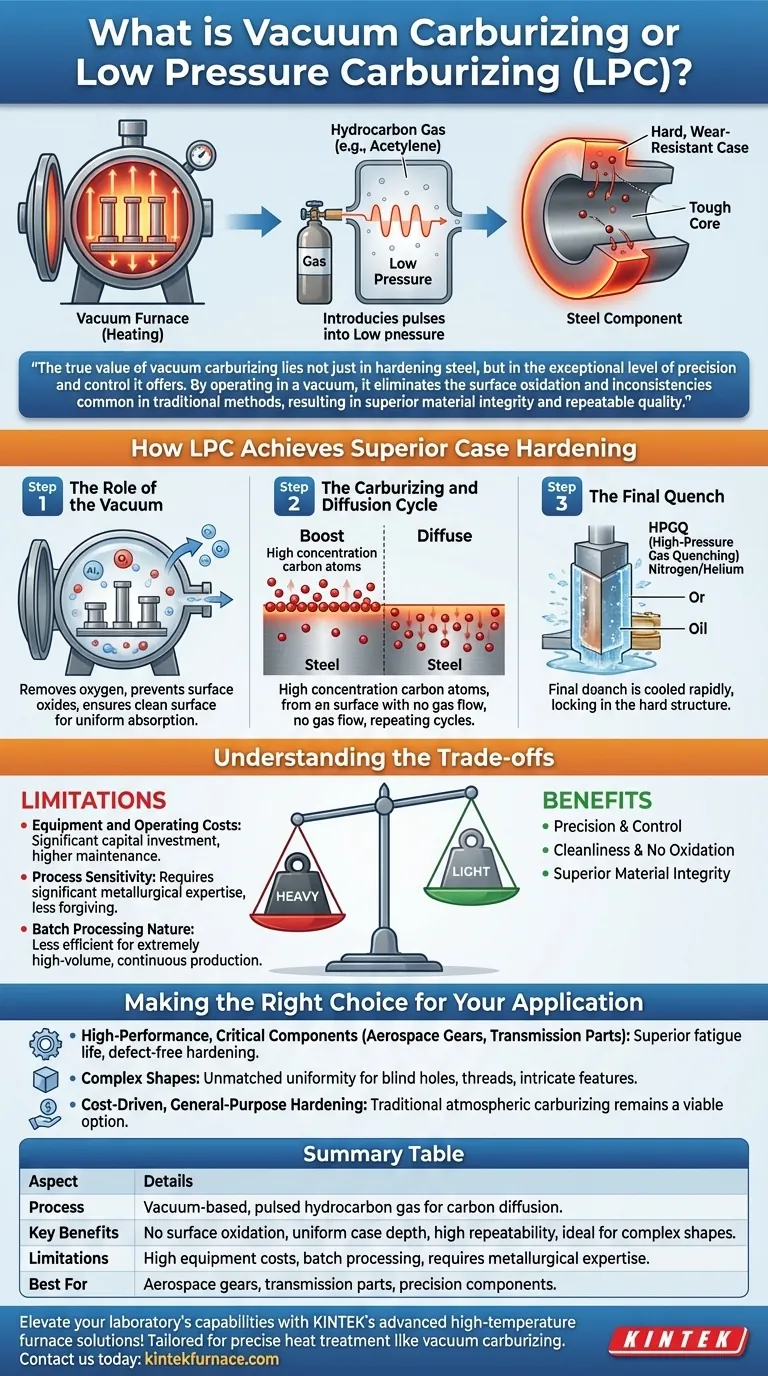

In essence, vacuum carburizing, also known as low-pressure carburizing (LPC), is a modern case-hardening process for steel components. It takes place in a vacuum furnace where parts are heated to a high temperature, and a hydrocarbon gas like acetylene is introduced at very low pressure. The gas breaks down, allowing carbon atoms to diffuse into the surface of the steel, creating an extremely hard, wear-resistant outer layer called a "case" while the core remains tough.

The true value of vacuum carburizing lies not just in hardening steel, but in the exceptional level of precision and control it offers. By operating in a vacuum, it eliminates the surface oxidation and inconsistencies common in traditional methods, resulting in superior material integrity and repeatable quality.

How LPC Achieves Superior Case Hardening

The LPC process is a carefully orchestrated sequence of steps designed to maximize control and metallurgical quality. It fundamentally differs from older, atmosphere-based methods by first creating a perfectly clean environment.

The Role of the Vacuum

The process begins by placing parts in a furnace and pumping out the air to create a vacuum. This initial step is critical because it removes oxygen and other reactive gases.

By removing oxygen, LPC completely prevents the formation of surface oxides or scale. This ensures the steel surface is perfectly clean and ready to absorb carbon uniformly.

The Carburizing and Diffusion Cycle

Unlike traditional methods that continuously surround parts in a carbon-rich atmosphere, LPC uses a precise, pulsed approach.

First, a small, measured amount of carburizing gas (typically acetylene) is introduced into the hot furnace. At high temperatures and low pressure, the gas breaks down, rapidly saturating the steel's immediate surface with carbon.

Next, the gas flow is stopped. The process enters a "diffusion" stage where the high concentration of carbon on the surface naturally drives itself deeper into the part, creating the desired case depth. This "boost and diffuse" cycle can be repeated multiple times to achieve a precise carbon profile.

The Final Quench

Once the desired case depth is reached, the parts must be cooled rapidly, or "quenched," to lock in the hard metallurgical structure. This is typically done using high-pressure gas quenching (HPGQ) with nitrogen or helium, or sometimes with oil. This final step solidifies the hard, wear-resistant case.

Understanding the Trade-offs

While LPC offers significant advantages, it is essential to understand its limitations to determine if it is the right process for your application.

Equipment and Operating Costs

Vacuum furnaces are a significant capital investment, costing substantially more than traditional atmospheric furnaces. The sophisticated control systems and vacuum pumps also contribute to higher maintenance costs.

Process Sensitivity

Although the process is highly automated and repeatable, developing the correct recipe of temperature, time, and gas cycles for a specific part and material requires significant metallurgical expertise. It is less forgiving of improper setup than some older methods.

Batch Processing Nature

LPC is a batch process, which may be less efficient for extremely high-volume, continuous production lines compared to some large-scale atmospheric furnace setups.

Making the Right Choice for Your Application

Selecting the right carburizing method depends entirely on the performance requirements and economic constraints of your component.

- If your primary focus is high-performance, critical components: LPC is the definitive choice for parts like aerospace gears or high-end transmission components where superior fatigue life and the absence of surface defects are non-negotiable.

- If your primary focus is parts with complex shapes: LPC provides unmatched uniformity, ensuring that blind holes, threads, and intricate features receive a consistent case depth.

- If your primary focus is cost-driven, general-purpose hardening: Traditional atmospheric carburizing remains a viable and more economical option for applications where the ultimate metallurgical perfection of LPC is not required.

Ultimately, choosing vacuum carburizing is a strategic decision for applications where precision, cleanliness, and uncompromising material performance are paramount.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Vacuum-based case hardening using pulsed hydrocarbon gas for carbon diffusion |

| Key Benefits | No surface oxidation, uniform case depth, high repeatability, ideal for complex shapes |

| Limitations | High equipment costs, batch processing, requires metallurgical expertise |

| Best For | Aerospace gears, transmission parts, and components needing precise, defect-free hardening |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for precise heat treatment like vacuum carburizing. Our strong deep customization ensures your unique experimental requirements are met with reliability and efficiency. Ready to achieve superior material performance? Contact us today to discuss how our solutions can benefit your high-performance applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today