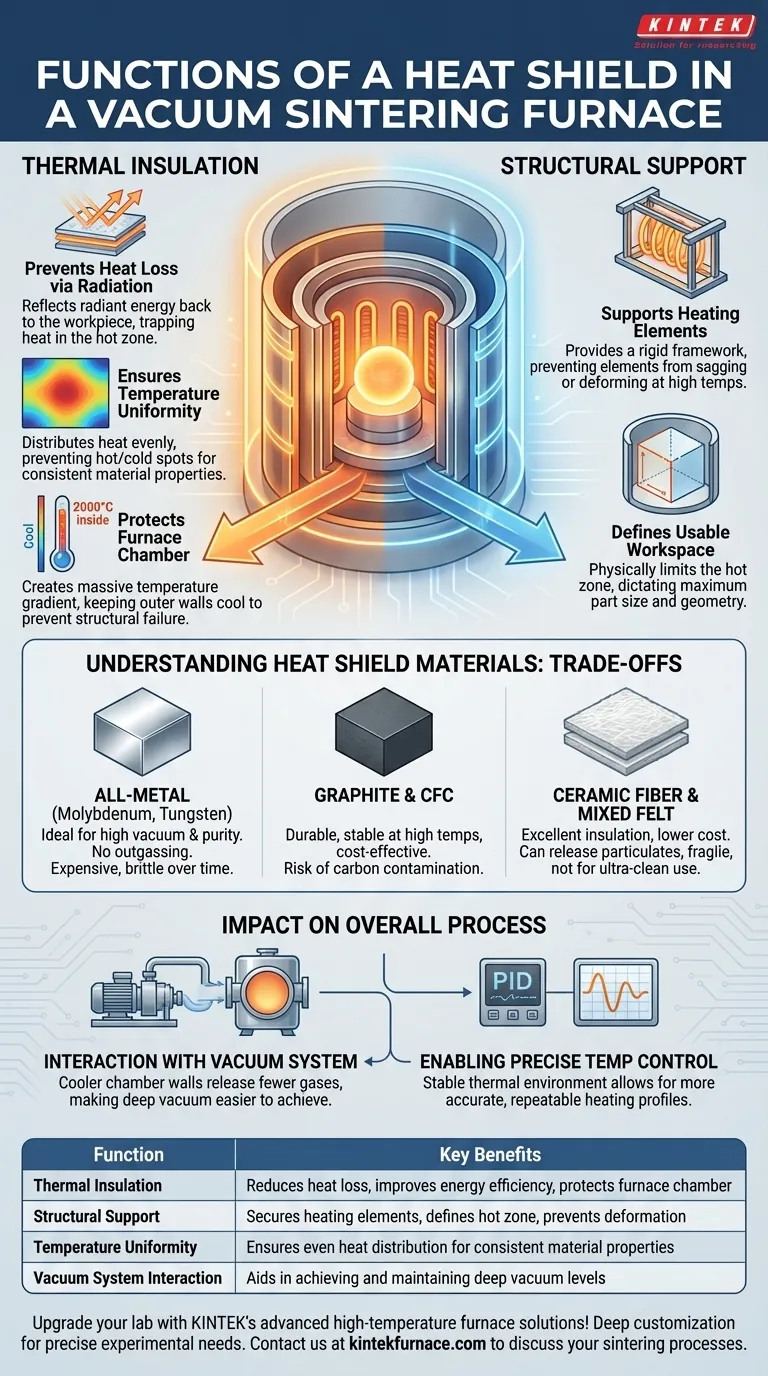

At its core, the heat shield in a vacuum sintering furnace serves two primary functions. It provides critical thermal insulation to contain extreme heat, reduce energy loss, and protect the furnace chamber. Simultaneously, it acts as the structural support frame for the heating elements, holding them securely in place within the hot zone.

The heat shield is more than just insulation; it is a critical component that directly enables the extreme temperature and high-purity environment required for successful vacuum sintering. Its design dictates the furnace's energy efficiency, temperature uniformity, and the ultimate quality of the final product.

The Critical Role of Thermal Management

The primary purpose of a vacuum furnace is to achieve precise temperatures in an inert environment. The heat shield is the component most responsible for managing the thermal energy required to do this.

Preventing Heat Loss via Radiation

In a vacuum, heat transfer via convection is virtually eliminated. Therefore, the dominant mode of heat transfer is thermal radiation. The heat shield consists of multiple layers of reflective material that bounce this radiant energy back towards the workpiece, effectively trapping it within the hot zone.

Ensuring Temperature Uniformity

A well-designed shield assembly ensures that this reflected heat is distributed evenly around the workload. This prevents hot or cold spots, which is crucial for achieving consistent density, grain structure, and material properties throughout the sintered part.

Protecting the Furnace Chamber

The heat shield creates a massive temperature gradient, allowing the interior to be over 2000°C while the exterior water-cooled chamber walls remain near room temperature. This protection is essential to prevent the structural failure or warping of the furnace vessel itself.

The Structural Foundation of the Hot Zone

Beyond thermal control, the heat shield assembly is a fundamental structural component of the furnace's interior.

Supporting the Heating Elements

Heating elements, whether made of graphite or refractory metals like molybdenum, become soft and pliable at operating temperatures. The heat shield provides a rigid framework that secures these elements, preventing them from sagging, deforming, or shorting out during a cycle.

Defining the Usable Workspace

The internal dimensions of the heat shield assembly physically define the "hot zone." This dictates the maximum size and geometry of the parts that can be processed within the furnace.

Understanding the Trade-offs: Heat Shield Materials

The choice of heat shield material is a critical engineering decision driven by temperature, the material being sintered, and vacuum requirements. There is no single "best" option.

All-Metal Shields (Molybdenum, Tungsten)

These shields are ideal for processes requiring high vacuum and extreme cleanliness. They do not release gases ("outgas") that could contaminate sensitive materials. However, they are expensive and can become brittle after repeated thermal cycles.

Graphite and Carbon Fiber Composite (CFC) Shields

Graphite-based shields are highly durable, structurally stable at very high temperatures, and more cost-effective. Their main drawback is the potential to introduce carbon into the furnace atmosphere, making them unsuitable for sintering materials that react with carbon.

Ceramic Fiber and Mixed Felt Shields

These materials offer excellent insulation properties at a lower cost. However, they are more susceptible to releasing fine particulates, can be fragile, and are generally not used for ultra-clean or very high-temperature applications.

How the Shield Impacts the Overall Process

The heat shield does not operate in isolation. Its performance directly affects the other critical systems of the furnace.

Interaction with the Vacuum System

By effectively containing heat, the shield reduces the thermal load on the furnace's steel chamber walls. Cooler walls release fewer trapped gases, making it easier for the vacuum pumps to achieve and maintain the deep vacuum levels required for a pure environment.

Enabling Precise Temperature Control

A highly efficient heat shield creates a stable thermal environment. This allows the temperature control system (using thermocouples and PID controllers) to make smaller, more precise adjustments, resulting in a more accurate and repeatable heating profile.

Making the Right Choice for Your Application

The ideal heat shield is determined by your specific material, temperature, and cleanliness requirements.

- If your primary focus is high-purity sintering of reactive metals: An all-metal shield (like molybdenum) is the superior choice to avoid atmospheric contamination.

- If your primary focus is high-temperature sintering of carbides or non-sensitive materials: A graphite or CFC shield provides the best balance of performance, durability, and cost-effectiveness.

- If your primary focus is maximizing energy efficiency at lower temperatures: A mixed felt or ceramic fiber shield can be a viable option, provided particulate contamination is not a critical concern.

Ultimately, understanding the function of the heat shield is key to controlling the entire furnace environment and achieving consistent, high-quality results.

Summary Table:

| Function | Key Benefits |

|---|---|

| Thermal Insulation | Reduces heat loss, improves energy efficiency, protects furnace chamber |

| Structural Support | Secures heating elements, defines hot zone, prevents deformation |

| Temperature Uniformity | Ensures even heat distribution for consistent material properties |

| Vacuum System Interaction | Aids in achieving and maintaining deep vacuum levels |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how our heat shield technologies and full product line can benefit your sintering processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments