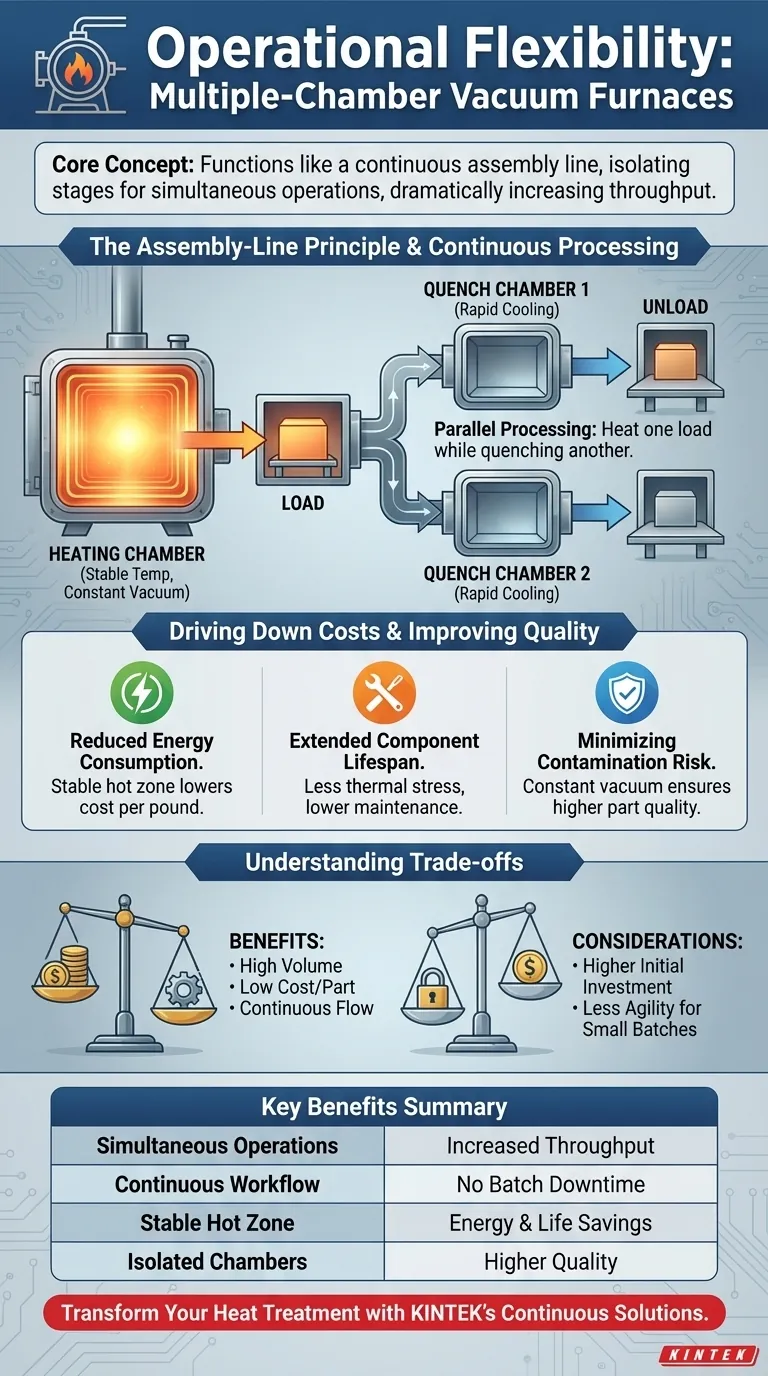

At its core, the operational flexibility of a multiple-chamber vacuum furnace stems from its ability to function like a continuous assembly line rather than a standalone batch processor. By isolating different process stages—such as loading, heating, and quenching—into separate, interconnected chambers, these systems can perform multiple operations simultaneously. This allows a new load to be heated while the previous one is being quenched, dramatically increasing throughput and overall process efficiency.

The true value of a multiple-chamber furnace isn't just its flexibility, but how that flexibility fundamentally changes the production model. It moves heat treatment from a stop-and-start batch process to a continuous, highly efficient workflow, leading to significant reductions in cost per part and major gains in productivity.

Enabling Continuous, High-Throughput Processing

The primary advantage of a multi-chamber design is its ability to decouple process steps, which unlocks a new level of efficiency that is impossible to achieve with a single-chamber furnace.

The Assembly-Line Principle

A multi-chamber furnace transforms heat treatment into a continuous flow. Parts move sequentially from one dedicated chamber to the next without breaking the master vacuum or waiting for a single chamber to complete an entire cycle.

This design eliminates the significant downtime inherent in single-chamber systems, where the entire furnace is occupied by one load from initial pump-down to final cooling.

Simultaneous Heating and Quenching

The most powerful feature is the ability to run heating and quenching cycles in parallel. While one load is being brought to temperature in the hot zone, a previously heated load can be transferred to a separate quench chamber.

This parallel processing effectively cuts the total cycle time per load, as the heating of the next batch begins immediately after the previous one is moved, rather than waiting for the entire furnace to cool and be reloaded.

Eliminating Batch-to-Batch Downtime

In a single-chamber furnace, the hot zone must be cooled, vented to atmosphere, reloaded, and then pumped back down to vacuum for every single batch. This constant cycling consumes enormous amounts of time and energy.

Multi-chamber systems keep the heating chamber permanently under vacuum and at or near operating temperature. Loads are introduced via a loading chamber, preserving the integrity of the hot zone and allowing for near-instantaneous processing of the next batch.

Driving Down Operational and Maintenance Costs

This enhanced workflow directly translates into lower long-term costs associated with energy, maintenance, and part quality.

Reducing Energy Consumption

The single largest energy waste in batch processing is the repeated heating and cooling of the furnace's hot zone and insulation.

Because a multi-chamber furnace's hot zone remains at a stable temperature, energy is only used to heat the product itself, not the entire furnace structure over and over again. This drastically lowers the energy cost per pound of material processed.

Extending Component Lifespan

Mechanical stress from repeated thermal and pressure cycling is a primary cause of furnace component failure. The heating elements, insulation, and chamber vessel are all stressed during each cycle.

In a multi-chamber design, the main heating chamber is not subjected to constant pressure changes or wide temperature swings. This stable environment significantly extends furnace life, reduces casing fatigue, and lowers maintenance costs.

Minimizing Contamination Risk

Each time a single-chamber furnace is opened to the atmosphere, it introduces moisture and oxygen, which can lead to oxidation and inconsistent product quality.

By maintaining a constant vacuum in the heating and transfer chambers, multi-chamber systems provide a purer processing environment, ensuring higher part quality and repeatability.

Understanding the Trade-offs

While powerful, a multi-chamber system is not the universal solution. Its benefits come with specific considerations.

Higher Initial Capital Investment

The complexity of multiple chambers, transfer mechanisms, and sophisticated control systems results in a significantly higher upfront cost compared to a standard single-chamber batch furnace. The investment must be justified by sufficient production volume.

Reduced Process Agility

Multi-chamber furnaces are typically optimized for a specific, repeatable production flow. While flexible in quenching, they are less agile than a standalone batch furnace for handling frequent, one-off jobs or experimental processes that deviate from the established workflow.

Configuration and Footprint

The layout of a multi-chamber system (e.g., straight-through, Cloverleaf) has a larger and more complex footprint than a single furnace. Plant layout and material flow must be carefully considered during the planning phase. Some designs, like the Cloverleaf, offer maintenance advantages by allowing individual chambers to be serviced while others remain operational.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your production philosophy and business objectives.

- If your primary focus is maximizing throughput for a consistent, high-volume product: A multiple-chamber continuous system is the definitive choice for achieving assembly-line efficiency.

- If your primary focus is minimizing long-term operational cost per part: The energy and maintenance savings of a multi-chamber design will almost certainly deliver a lower total cost of ownership in a high-production environment.

- If your primary focus is versatility for low-volume, high-mix, or R&D work: The simplicity and lower initial cost of a single-chamber batch furnace may be the more practical and cost-effective solution.

Ultimately, choosing a multi-chamber furnace is a strategic decision to adopt a continuous flow philosophy for your heat treatment operations.

Summary Table:

| Feature | Benefit |

|---|---|

| Simultaneous heating and quenching | Increases throughput by parallel processing |

| Continuous workflow | Eliminates batch-to-batch downtime |

| Stable hot zone | Reduces energy consumption and extends component life |

| Isolated chambers | Minimizes contamination for higher part quality |

Ready to transform your heat treatment process with continuous, high-throughput solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our multi-chamber vacuum furnaces can enhance your productivity and reduce operational costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion