Specifically, hot wall vacuum furnaces are primarily used for lower-temperature heat treatments that demand exceptional thermal uniformity over long cycles. These include processes like tempering, brazing, coating, curing, and specific types of case hardening such as nitriding, nitrocarburizing, and sulfonitriding where precise control is paramount.

A hot wall furnace is not simply a vacuum furnace; it is a specific design optimized for stability over speed. Its value lies in creating a perfectly uniform, controlled environment for sensitive, long-duration processes, making it the ideal choice for surface modification and low-temperature treatments.

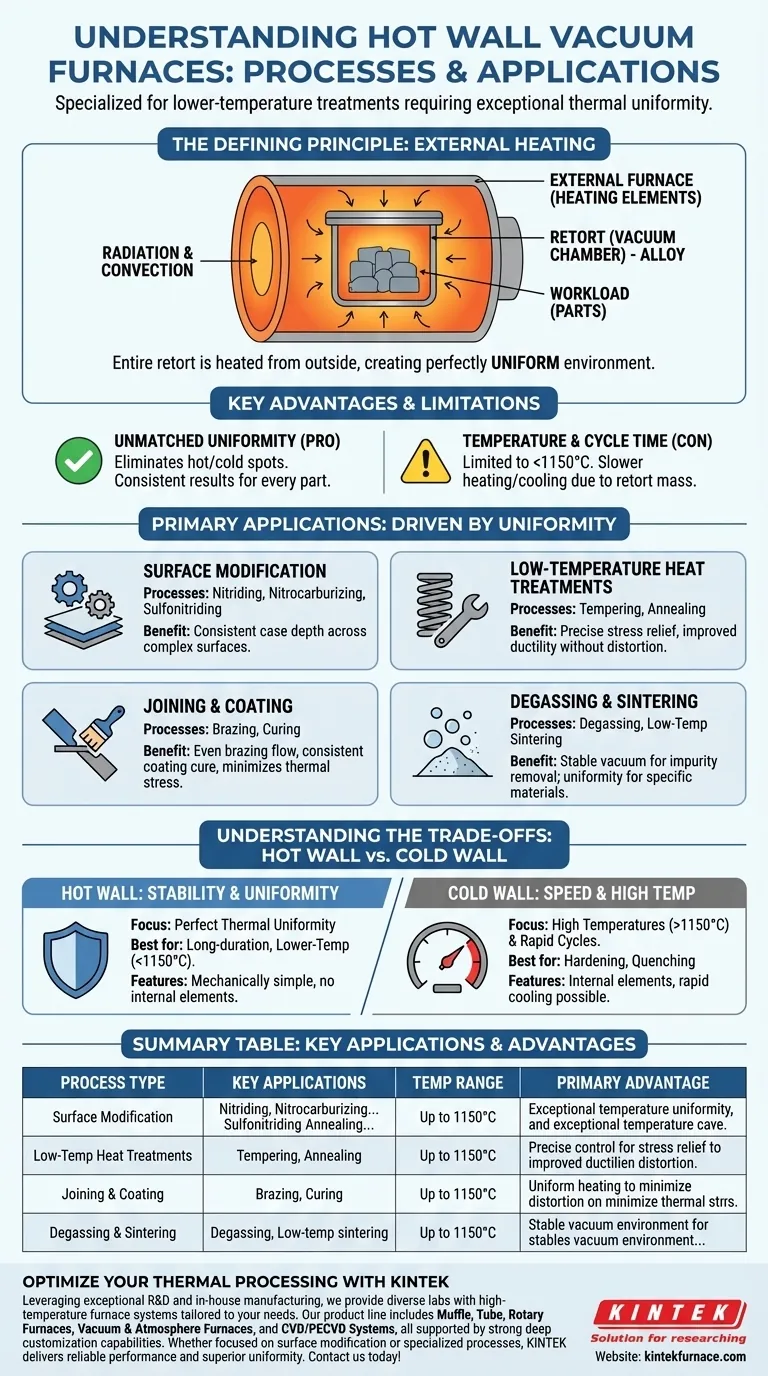

The Defining Principle of a Hot Wall Furnace

To understand its applications, you must first understand its design. A hot wall furnace operates on a fundamentally different principle than its more common "cold wall" counterpart.

What "Hot Wall" Means

In a hot wall furnace, the vacuum chamber, known as a retort, is a sealed container made of a high-temperature alloy. This entire retort is placed inside an external, larger furnace that heats it from the outside.

The vacuum is maintained within the retort, while the heating elements are outside of it. The retort's walls become hot, transferring heat to the parts inside primarily through radiation and convection.

The Key Advantage: Unmatched Temperature Uniformity

Because the entire retort is "soaked" in heat from all sides, the temperature environment inside becomes exceptionally uniform. This eliminates hot or cold spots that can occur with internal heating elements.

This superior uniformity is the primary reason a hot wall design is chosen. It ensures every part of the workload experiences the exact same thermal conditions.

The Inherent Limitation: Temperature and Cycle Time

This design is generally limited to lower operating temperatures, typically below 1150°C (2100°F), due to the material strength of the retort itself at high temperatures.

Heating and cooling cycles are also significantly slower compared to cold wall furnaces, as the entire mass of the retort and the surrounding furnace insulation must be heated and cooled.

Primary Applications Driven by Hot Wall Design

The unique advantages and limitations of the hot wall design make it perfectly suited for a specific set of thermal processes.

Surface Modification Processes

Processes like nitriding, nitrocarburizing, and sulfonitriding are ideal for hot wall furnaces. These are case hardening techniques that require holding a component at a precise, moderate temperature for many hours in a specialized gas atmosphere.

The sealed retort contains the process gas (e.g., ammonia for nitriding) perfectly, and the exceptional temperature uniformity ensures a consistent case depth across the entire part surface.

Low-Temperature Heat Treatments

Tempering and annealing are classic hot wall applications. These processes are used to reduce hardness, relieve internal stresses, and improve ductility.

Success depends on holding the material at a very precise temperature, often for extended periods. The stability and uniformity of a hot wall furnace guarantee repeatable, high-quality results without distortion.

Joining and Coating

Lower-temperature brazing and curing operations benefit greatly from the hot wall design. Uniform heating is critical to ensure the brazing filler metal flows evenly or that a coating cures consistently across a complex geometry.

The slow, controlled heating and cooling cycles also help minimize thermal stress and potential distortion in delicate assemblies.

Degassing and Sintering

Hot wall furnaces are also used for degassing or impurity removal, where a long, stable soak in a vacuum effectively draws out unwanted contaminants.

While very high-temperature sintering is reserved for cold wall designs, hot wall furnaces are effective for sintering lower-temperature materials like certain metal powders and ceramics where uniformity is more critical than peak temperature.

Understanding the Trade-offs: Hot Wall vs. Cold Wall

Choosing the correct furnace is a critical engineering decision based on clear trade-offs.

When to Choose Hot Wall: Uniformity and Simplicity

A hot wall furnace is the correct choice for lower-temperature processes where perfect thermal uniformity is the most critical factor.

Its design is also mechanically simpler, with no internal heating elements, power feedthroughs, or complex heat shielding inside the vacuum zone, which can simplify maintenance.

When to Choose Cold Wall: Speed and High Temperatures

A cold wall furnace, where the heating elements are inside a water-cooled vacuum vessel, is required for high-temperature applications (>1150°C).

It is also necessary for any process requiring rapid heating and cooling, such as vacuum hardening with an integrated gas quench. The low thermal mass of the internal hot zone allows for cycle times that are impossible in a hot wall furnace.

Selecting the Right Furnace for Your Process

Your choice between a hot wall and cold wall design depends entirely on your process requirements for temperature, cycle time, and uniformity.

- If your primary focus is precise, uniform heating for long-duration, lower-temperature processes like nitriding or tempering: A hot wall furnace is the superior and more efficient choice.

- If your primary focus is high-temperature applications (>1150°C) or processes requiring rapid cooling like hardening and quenching: You must use a cold wall vacuum furnace.

- If your primary focus is brazing or sintering: Your material dictates the choice; lower-temperature variants are well-suited for hot wall furnaces, while high-temperature work demands a cold wall design.

Understanding this fundamental design difference empowers you to select the most effective and efficient tool for your specific thermal processing goal.

Summary Table:

| Process Type | Key Applications | Temperature Range | Primary Advantage |

|---|---|---|---|

| Surface Modification | Nitriding, Nitrocarburizing, Sulfonitriding | Up to 1150°C | Exceptional temperature uniformity for consistent case depth |

| Low-Temperature Heat Treatments | Tempering, Annealing | Up to 1150°C | Precise control for stress relief and ductility improvement |

| Joining and Coating | Brazing, Curing | Up to 1150°C | Uniform heating to minimize distortion and ensure even flow |

| Degassing and Sintering | Degassing, Low-temperature sintering | Up to 1150°C | Stable vacuum environment for impurity removal and material processing |

Optimize your laboratory's thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're focused on surface modification, low-temperature treatments, or other specialized processes, KINTEK delivers reliable performance and superior uniformity. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance