In short, a vacuum furnace achieves its energy efficiency through three core mechanisms. The vacuum environment itself virtually eliminates heat loss from gas convection, advanced insulation materials minimize heat loss through conduction and radiation, and modern control systems ensure energy is used precisely when and where it is needed. This combination is further enhanced by rapid cooling capabilities that shorten overall process times, reducing total energy consumption per cycle.

A vacuum furnace's efficiency is not just a feature; it's a fundamental consequence of its design. By removing air and other gases, it eliminates a primary path of heat loss found in conventional furnaces, allowing for more direct, controlled, and effective use of energy.

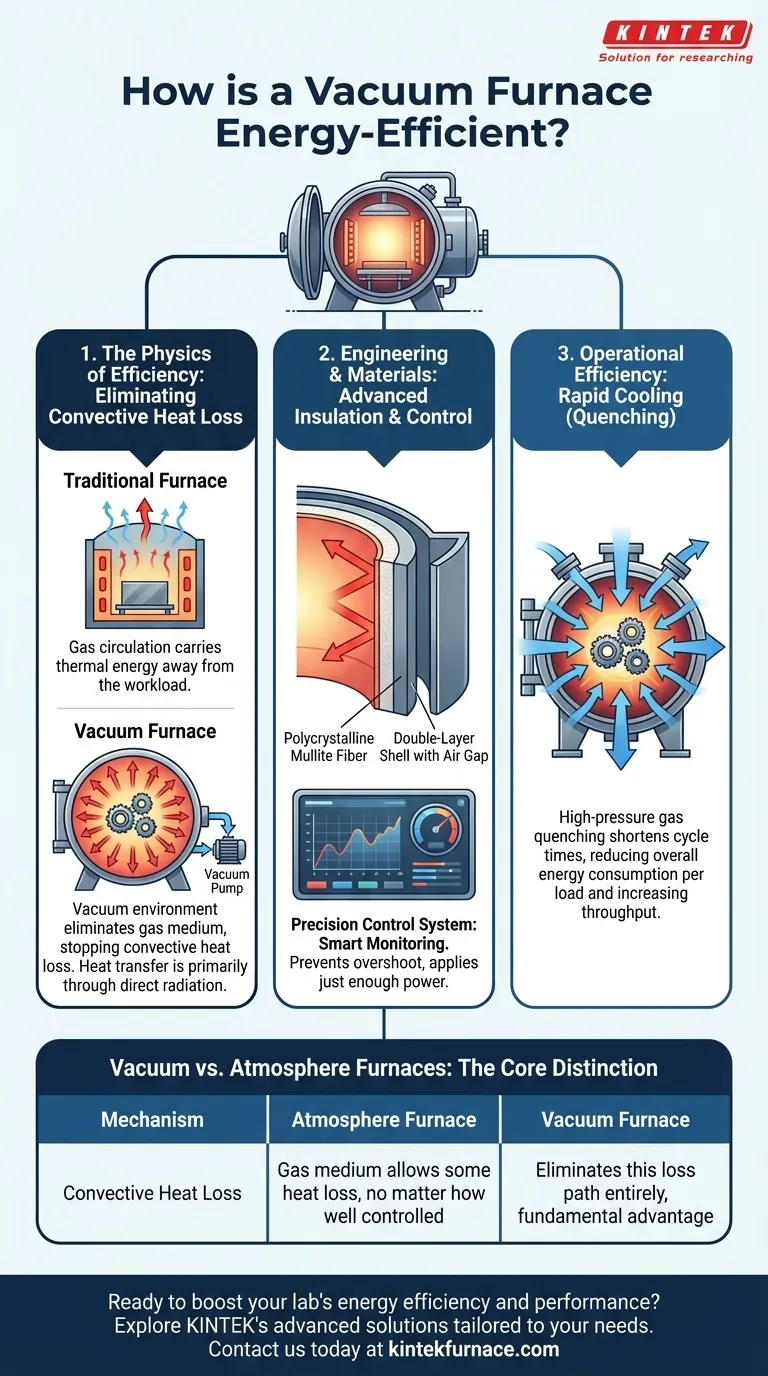

The Physics of Efficiency: How a Vacuum Works for You

To understand a vacuum furnace's efficiency, you must first appreciate the role of the vacuum itself. It is not merely an absence of gas, but an active component in thermal management.

Eliminating Convective Heat Loss

In a traditional furnace, air or an atmosphere gas becomes heated and circulates, carrying thermal energy away from the heating elements and the workpiece. This process, known as convection, is a major source of heat loss.

By removing nearly all gas molecules, a vacuum furnace effectively stops convective heat loss. There is no medium to carry heat away, meaning more energy remains concentrated within the heating zone where it is needed.

Enabling Superior Heat Transfer

With convection removed, heat transfer in a vacuum occurs primarily through radiation. The heating elements radiate thermal energy directly to the parts being treated.

This direct, line-of-sight energy transfer is highly efficient. It avoids wasting energy on heating an intermediate gas, ensuring the power you pay for is focused on heating your product.

Engineering and Materials: The Supporting Pillars

While the vacuum environment is foundational, the physical construction of the furnace is what truly capitalizes on this advantage.

Advanced Insulation Packages

Modern vacuum furnaces use multi-layered insulation made from high-quality materials like polycrystalline mullite fiber. This insulation is designed to reflect radiant heat back into the chamber and prevent it from escaping through the furnace walls.

Some designs also incorporate double-layer furnace shells with air gaps, using air itself as an additional, low-cost insulator to further minimize thermal leakage to the surrounding environment.

Precision Control Systems

Efficiency is impossible without control. Advanced control systems continuously monitor temperature and automatically adjust power to the heating elements.

This ensures the furnace does not overshoot its target temperature, a common source of wasted energy. The system applies just enough power to maintain the optimal conditions required for the process, improving both efficiency and metallurgical results.

The Role of Rapid Cooling (Quenching)

Efficiency isn't just about the heating phase. The ability to rapidly cool (or quench) the workload using high-pressure gas shortens the entire process from start to finish.

Shorter cycle times mean the furnace runs for less time per load. This directly translates to lower overall kilowatt-hour consumption and increases the throughput of your facility, boosting operational efficiency.

Understanding the Trade-offs: Vacuum vs. Atmosphere Furnaces

While highly efficient, vacuum furnaces are not the only option. It's helpful to compare them against atmosphere furnaces to understand the core differences in their approach to efficiency.

The Atmosphere Furnace Approach

Atmosphere furnaces also create a controlled environment, but they do so by filling the chamber with a specific inert gas. This gas prevents oxidation and reduces heat loss compared to an open-air furnace.

Like vacuum furnaces, they utilize advanced control systems to optimize heating parameters and minimize energy waste.

The Core Distinction

The fundamental difference lies in the medium. An atmosphere furnace must constantly manage and heat a large volume of gas, which inherently allows for some convective heat loss, no matter how well controlled.

A vacuum furnace, by its nature, eliminates this path of energy loss entirely. This gives it a fundamental thermodynamic advantage in preventing unwanted heat transfer and maximizing the energy directed at the workload.

Making the Right Choice for Your Process

The decision between different heat treatment technologies depends entirely on your specific goals for part quality, operational speed, and cost.

- If your primary focus is maximum energy efficiency and part cleanliness: A vacuum furnace's ability to eliminate both convective heat loss and oxidation makes it the superior technical choice.

- If your primary focus is throughput and process speed: The rapid quenching capabilities available in many vacuum furnaces can drastically reduce cycle times, making them highly efficient from an operational standpoint.

- If your primary focus is cost-sensitive processing that doesn't require a perfect vacuum: A modern atmosphere furnace offers a significant efficiency improvement over older methods and can be a highly effective solution.

Understanding these core principles of heat transfer empowers you to select the technology that best aligns with your specific operational and financial goals.

Summary Table:

| Mechanism | Key Benefit |

|---|---|

| Vacuum Environment | Eliminates convective heat loss for direct energy focus |

| Advanced Insulation | Minimizes heat loss through conduction and radiation |

| Precision Control Systems | Ensures optimal energy use and prevents overshooting |

| Rapid Cooling Capabilities | Shortens cycle times, reducing total energy consumption |

Ready to boost your lab's energy efficiency and performance? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to learn how our vacuum furnaces can deliver superior heat treatment with lower energy costs and faster cycles!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing