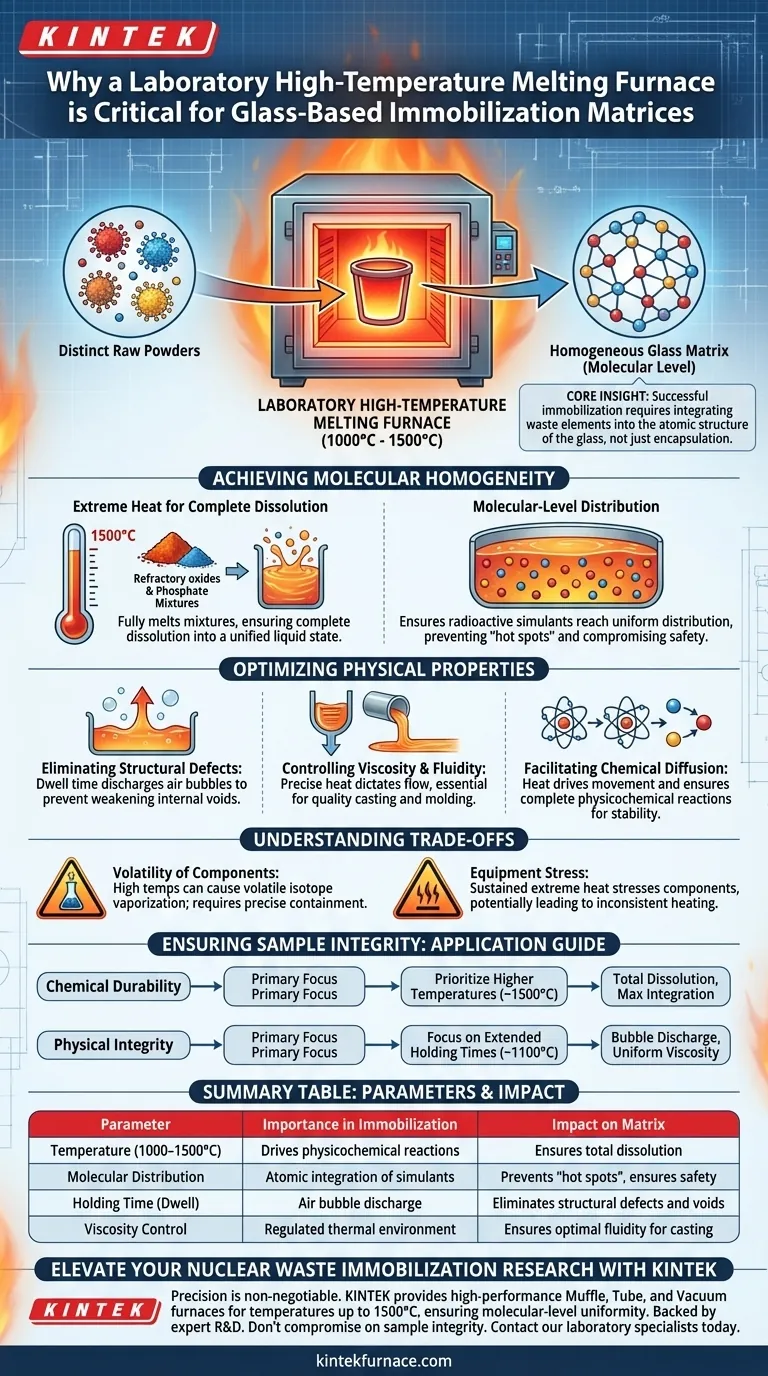

A laboratory high-temperature melting furnace is the foundational tool for creating effective glass-based immobilization matrices. It provides a strictly controlled thermal environment, typically operating between 1000°C and 1500°C, which is necessary to thoroughly melt oxide and phosphate mixtures. This intense, regulated heat ensures that radioactive element simulants are distributed uniformly at a molecular level, a requirement for producing high-performance solidification samples that can safely contain hazardous materials.

Core Insight: Successful immobilization is not merely about encapsulation; it requires integrating waste elements into the atomic structure of the glass. The furnace provides the precise energy required to drive the physicochemical reactions that transform distinct raw powders into a single, homogeneous, and stable glass phase.

Achieving Molecular Homogeneity

The Necessity of Extreme Heat

To immobilize radioactive simulants effectively, you cannot simply suspend them in a binder; they must become part of the glass network.

The furnace generates temperatures up to 1500°C to fully melt refractory oxide and phosphate mixtures. This ensures the complete dissolution of raw materials into a unified liquid state.

Molecular-Level Distribution

The primary goal of this thermal process is uniformity.

By maintaining high temperatures, the furnace ensures that radioactive element simulants reach a molecular-level uniform distribution within the melt. Without this, the final solid would have "hot spots" of concentrated waste, compromising the safety and stability of the matrix.

Optimizing Physical Properties

Eliminating Structural Defects

A stable glass matrix must be free of voids and internal weaknesses.

The furnace allows for specific holding times, such as 60 minutes at constant heat. This dwell time is critical for discharging internal air bubbles that would otherwise weaken the final structure.

Controlling Viscosity and Fluidity

The quality of the final casting relies heavily on the flow characteristics of the molten glass.

Precise temperature control dictates the viscosity and fluidity of the melt. If the temperature fluctuates, the viscosity changes, potentially leading to poor molding or incomplete casting of the final sample.

Facilitating Chemical Diffusion

Heat drives the movement of atoms within the mixture.

The controlled environment facilitates the diffusion of chemical components throughout the batch. This diffusion is essential for thermal decomposition and ensuring the physicochemical reactions required to stabilize the waste elements occur completely.

Understanding the Trade-offs

While high-temperature furnaces are critical, relying on thermal processing introduces specific challenges that must be managed.

Volatility of Components Operating at temperatures between 1000°C and 1500°C promotes thorough melting, but it can also cause volatile radioactive isotopes (such as Cesium or Technetium simulants) to vaporize. Precise temperature ramping and containment are required to prevent the loss of these elements before they are immobilized.

Equipment Stress The requirement for sustained, extreme heat places immense stress on heating elements and crucibles. Inconsistent heating due to equipment degradation can lead to temperature gradients within the melt, resulting in a non-uniform product despite correct settings.

Ensuring Sample Integrity

How to Apply This to Your Project

Selecting the right thermal profile is as important as the furnace itself. Use the following guide to prioritize your processing parameters:

- If your primary focus is Chemical Durability: Prioritize higher temperatures (closer to 1500°C) to ensure total dissolution of oxides and maximum molecular integration of the waste simulants.

- If your primary focus is Physical Integrity: Focus on extended holding times at stable temperatures (around 1100°C) to allow for complete bubble discharge and uniform viscosity for casting.

The ultimate success of your immobilization matrix depends on utilizing the furnace not just as a heater, but as a precision instrument for chemical synthesis.

Summary Table:

| Parameter | Importance in Immobilization | Impact on Matrix |

|---|---|---|

| Temperature (1000-1500°C) | Drives physicochemical reactions | Ensures total dissolution of refractory oxides |

| Molecular Distribution | Atomic integration of simulants | Prevents "hot spots" and ensures safety |

| Holding Time (Dwell) | Air bubble discharge | Eliminates structural defects and voids |

| Viscosity Control | Regulated thermal environment | Ensures optimal fluidity for casting and molding |

Elevate Your Nuclear Waste Immobilization Research with KINTEK

Precision is non-negotiable when dealing with radioactive element simulants. KINTEK provides high-performance Muffle, Tube, and Vacuum furnaces specifically engineered for temperatures up to 1500°C, ensuring the molecular-level uniformity your research demands.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to handle volatile isotopes and eliminate thermal gradients. Don't compromise on sample integrity.

Contact our laboratory specialists today to find the perfect thermal solution for your immobilization matrices.

Visual Guide

References

- S. V. Yudintsev, V. I. Malkovsky. Thermal Effects and Glass Crystallization in Composite Matrices for Immobilization of the Rare-Earth Element–Minor Actinide Fraction of High-Level Radioactive Waste. DOI: 10.3390/jcs8020070

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What are the options for cooling methods in a vacuum furnace? Optimize Material Properties with Precision Cooling

- What is the maximum working temperature of high temperature vacuum furnaces? Unlock Precision Heating Up to 2600°C

- What effects do nitrogen and argon cooling have on material properties? Optimize Hardness and Strength in Heat Treatment

- What factors must be controlled during furnace brazing to ensure a reliable joint? Master the 5 Key Variables for Strong Bonds

- What materials can be processed using a vacuum sintering furnace? Unlock High-Purity Processing for Reactive Materials

- Why are vacuum furnaces indispensable in modern manufacturing? Achieve Superior Material Purity and Performance

- Why is a programmable vacuum sintering furnace required? Ensure Superior Feldspathic to Zirconia Bonding