In a vacuum furnace, cooling is achieved through two primary mechanisms: slow natural cooling within the vacuum itself, or rapid forced cooling using a medium like inert gas or oil. The selection of a method is dictated by the specific heat treatment process being performed and the desired final properties of the material.

The choice of a vacuum furnace cooling method is not a matter of simple preference; it is a critical process variable that directly determines the final microstructure, hardness, and internal stress of the component being treated.

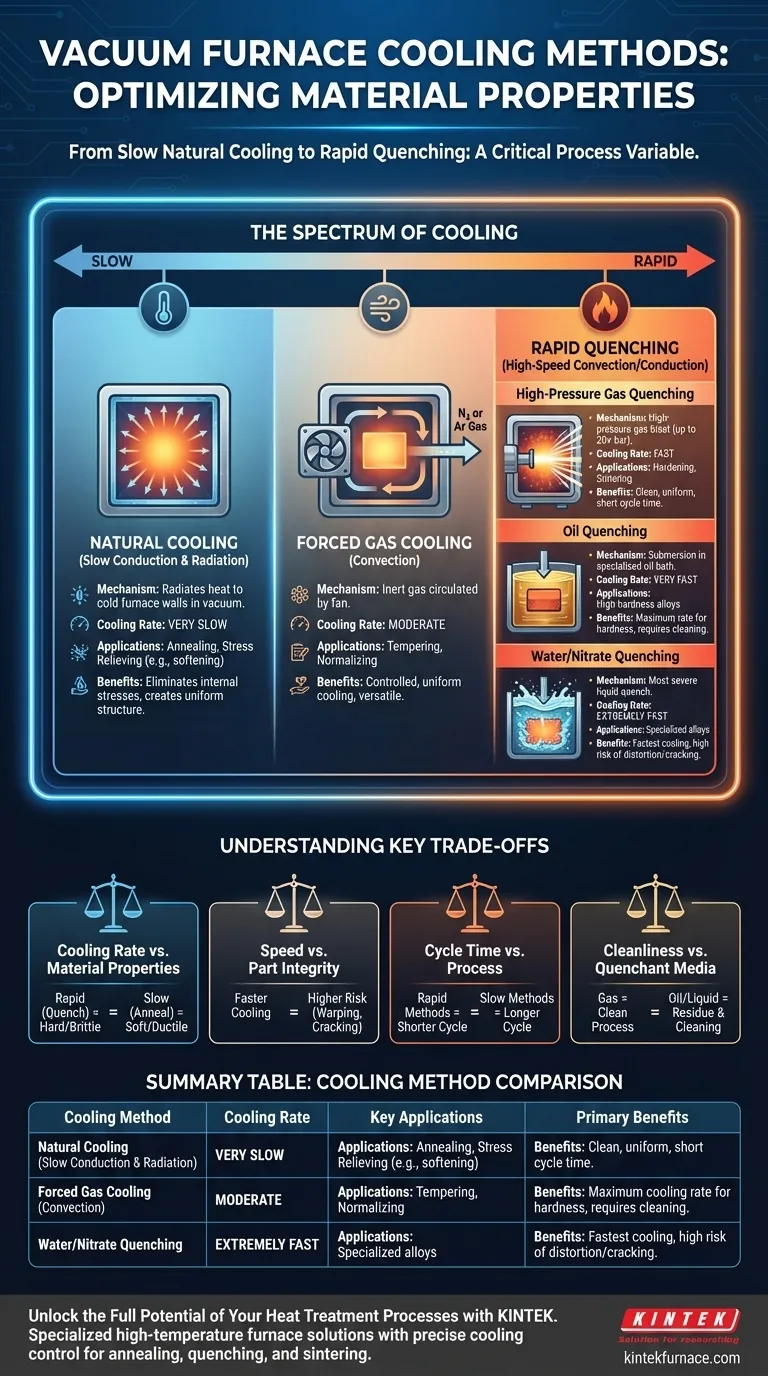

The Spectrum of Cooling: From Slow to Rapid

The cooling rate is arguably the most critical phase of any heat treatment cycle. Vacuum furnaces offer precise control over this rate, ranging from extremely slow to exceptionally fast.

Natural Cooling (Slow Conduction & Radiation)

Natural cooling is the slowest method available. After the heating cycle ends, the furnace is simply left under vacuum, and the workload cools by radiating heat to the cold walls of the furnace.

This slow, gentle process is essential for treatments like annealing or stress relieving, where the goal is to eliminate internal stresses and create a soft, uniform material structure.

Forced Gas Cooling (Convection)

To accelerate cooling beyond what natural radiation allows, an inert gas like nitrogen or argon is introduced into the hot zone and circulated by a fan.

This method, often called "gas cooling," provides a faster and more uniform cool-down. It's a versatile option used for processes like tempering or normalizing that require a controlled cooling rate faster than annealing but slower than a full quench.

Rapid Quenching (High-Speed Convection/Conduction)

Quenching is the process of cooling a metal at a rapid rate to achieve specific material properties, most notably hardness. Vacuum furnaces can integrate several quenching methods.

- High-Pressure Gas Quenching: This is a very common and clean quenching method. High-pressure inert gas (up to 20 bar or more) is blasted into the chamber, rapidly removing heat. It provides excellent uniformity and avoids the contamination associated with liquid quenches.

- Oil Quenching: For some alloys that require an even faster cooling rate than gas can provide, the workload is submerged into a bath of specialized quenching oil. This is often done in a sealed, separate chamber connected to the furnace. While effective, it requires post-process cleaning of the parts.

- Water or Nitrate Quenching: These are the most severe quenching methods, offering the fastest possible cooling rates. However, they are less common in vacuum furnaces due to the high risk of part distortion or cracking from extreme thermal shock and the complexity of integrating liquids into a vacuum environment.

Understanding the Key Trade-offs

Choosing a cooling method involves balancing the desired metallurgical outcome with process efficiency and potential risks. Understanding these trade-offs is crucial for successful heat treatment.

Cooling Rate vs. Material Properties

This is the fundamental principle of heat treatment. Rapid cooling (quenching) locks in a hard, brittle crystalline structure (like martensite in steel). Slow cooling (annealing) allows the structure to re-form into a soft, ductile state.

Speed vs. Part Integrity

The faster the cooling rate, the greater the thermal stress placed on the component. While a rapid quench is necessary for hardness, it also significantly increases the risk of warping, distortion, and cracking, especially in complex geometries.

Cycle Time vs. Process

Rapid cooling methods like high-pressure gas quenching dramatically shorten the overall process cycle time, increasing furnace throughput. Slow natural cooling, while necessary for annealing, can take many hours and occupies the furnace for a longer period.

Cleanliness vs. Quenchant Media

Gas quenching is an exceptionally clean process, delivering parts that require no subsequent cleaning. Oil quenching, by contrast, leaves an oily residue that must be washed off, adding an extra step and creating waste that needs to be managed.

Making the Right Choice for Your Process

Your choice of cooling method must be directly aligned with the goal of your specific heat treatment process.

- If your primary focus is maximum hardness and strength: You need a rapid quench, making high-pressure gas or oil quenching your necessary choice.

- If your primary focus is creating the softest possible material state and eliminating stress: You must use slow, natural cooling within the vacuum.

- If your primary focus is a balance of toughness and hardness (e.g., tempering): Controlled forced gas cooling provides the ideal, moderate cooling rate.

- If your primary focus is sintering powdered metals: A precisely programmed forced gas cooling cycle is essential to solidify the part without inducing thermal stress.

Ultimately, controlling the cooling process is just as important as controlling the heating process to achieve the desired material outcome.

Summary Table:

| Cooling Method | Cooling Rate | Key Applications | Primary Benefits |

|---|---|---|---|

| Natural Cooling | Very Slow | Annealing, Stress Relieving | Eliminates internal stresses, softens material |

| Forced Gas Cooling | Moderate | Tempering, Normalizing | Controlled, uniform cooling, versatile |

| High-Pressure Gas Quenching | Fast | Hardening, Sintering | Clean, uniform, reduces cycle time |

| Oil Quenching | Very Fast | High-hardness alloys | Maximum cooling rate for hardness |

| Water/Nitrate Quenching | Extremely Fast | Specialized alloys | Fastest cooling, high risk of distortion |

Unlock the Full Potential of Your Heat Treatment Processes with KINTEK

Are you struggling to achieve the right material properties in your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure precise cooling control for processes like annealing, quenching, and sintering, helping you enhance hardness, reduce stress, and optimize cycle times.

Contact us today via our contact form to discuss how our expertise can elevate your laboratory's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the working principles of a box furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- How do the operation and maintenance features of vacuum sintering furnaces enhance efficiency? Boost Productivity and Cut Costs

- What advantages does vacuum hardening offer? Achieve Superior, Distortion-Free Heat Treatment

- What are the key features of a vacuum furnace? Achieve Purity and Precision in Material Processing

- What is the primary role of a vacuum annealing furnace? Optimize AlSi10Mg LPBF Microstructure and Conductivity

- How does an annealing furnace achieve uniform temperature distribution? Master Heat Treatment Consistency

- What role does a high-temperature furnace play in CsPbCl3-MSN synthesis? Mastering Thermal Encapsulation

- How are heating element materials used in vacuum furnaces? A Guide to Temperature-Based Selection