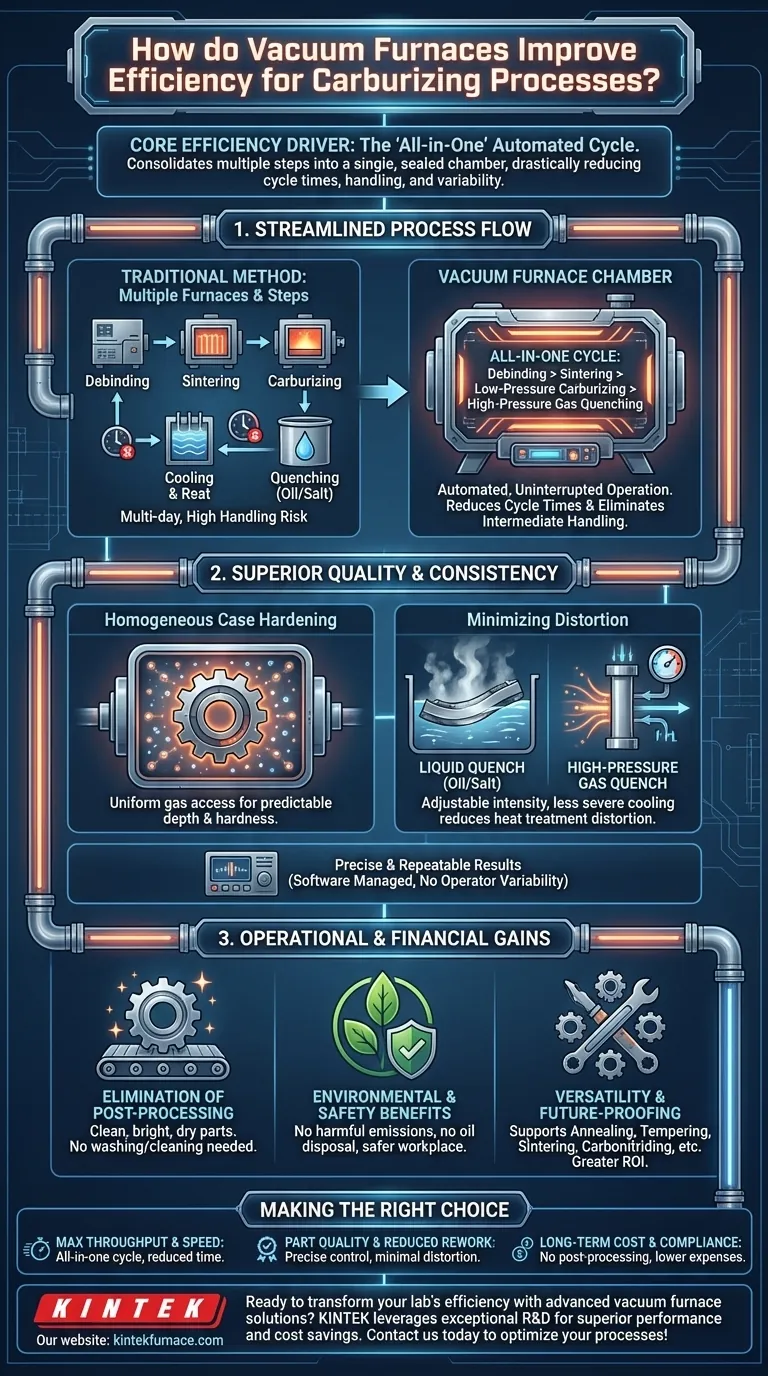

At its core, a vacuum furnace improves carburizing efficiency by integrating multiple heat treatment processes into a single, automated cycle. This consolidation drastically reduces overall cycle times, manual handling, and process variability compared to traditional atmosphere-based methods, which require moving parts between different pieces of equipment for steps like sintering, carburizing, and quenching.

The efficiency of vacuum carburizing extends far beyond simple speed. It represents a fundamental shift in process control, delivering superior part quality, eliminating entire post-processing steps, and creating a safer, cleaner, and more cost-effective operational environment.

The Core Efficiency Driver: The "All-in-One" Cycle

The most significant efficiency gain comes from the furnace's ability to perform a complete process sequence within a single, sealed chamber. This changes the entire production workflow.

Consolidating Process Steps

Instead of using separate furnaces for different stages, a modern vacuum furnace can manage debinding, sintering, low-pressure carburizing, and quenching in one uninterrupted cycle.

This "all-in-one" capability is the central advantage, turning a multi-day, multi-equipment process into a streamlined, automated operation.

Drastically Reducing Cycle Times

By eliminating the need to cool parts, move them to another furnace, and reheat them, you remove significant non-productive time from the schedule. The transition between process steps like sintering and carburizing becomes seamless.

Eliminating Intermediate Handling

Every time a part is moved between furnaces, it introduces risks of operator error, atmospheric contamination, and physical damage. A single-chamber process eradicates these risks, improving yield and reliability.

Achieving Superior Quality and Consistency

Efficiency is also measured by the quality of the final product. Fewer rejects and less rework translate directly to cost and time savings. The vacuum environment provides unparalleled control over metallurgical outcomes.

Homogeneous Case Hardening

In a vacuum, the carburizing gas can access all surfaces of the part uniformly. This ensures a highly homogeneous hardened case with predictable depth and hardness, a level of quality that is difficult to achieve in traditional atmosphere furnaces.

Minimizing Part Distortion

Vacuum furnaces use high-pressure gas quenching instead of liquid quenching (oil or salt). You can precisely control the gas pressure and velocity, allowing for an adjustable quenching intensity. This less severe, more controlled cooling process significantly reduces heat treatment distortion, minimizing the need for costly and time-consuming post-machining.

Precise and Repeatable Results

Modern vacuum furnaces are managed by sophisticated software that ensures every cycle runs identically. This removes operator variability and guarantees consistent, reproducible results that meet stringent quality standards like CQI-9.

Understanding the Operational and Financial Gains

The benefits of vacuum carburizing compound over time, creating a more efficient and profitable operation by addressing costs that exist outside the furnace itself.

The Elimination of Post-Processing

Parts emerge from a vacuum furnace clean, bright, and dry. This completely eliminates the need for secondary washing or cleaning operations that are mandatory after oil quenching, saving time, labor, floor space, and the cost of cleaning chemicals.

Environmental and Safety Benefits

Vacuum carburizing is an environmentally friendly process. It produces no harmful emissions, requires no disposal of used quenching oil or toxic chemicals, and eliminates the fire hazards associated with flammable atmospheres. This simplifies regulatory compliance and creates a cleaner, safer workplace.

Versatility and Future-Proofing

A single vacuum furnace is not a one-trick pony. It can be used for a wide range of thermal processes, including vacuum annealing, tempering, sintering, and carbonitriding. This versatility provides a greater return on the initial capital investment and makes your operation more agile.

Making the Right Choice for Your Goal

To determine if vacuum carburizing is the right fit, align its benefits with your primary operational drivers.

- If your primary focus is maximum throughput and speed: The all-in-one cycle of a vacuum furnace drastically reduces total processing time by consolidating steps and eliminating part handling.

- If your primary focus is part quality and reducing rework: The precise control over the vacuum environment minimizes distortion and delivers highly consistent, superior case hardening.

- If your primary focus is long-term operational cost and environmental compliance: Vacuum carburizing eliminates the need for part washing, chemical disposal, and emissions management, significantly lowering your ongoing operational expenses.

By shifting from traditional methods to a controlled vacuum environment, you gain a system that is not just faster, but fundamentally more precise, clean, and cost-effective.

Summary Table:

| Aspect | Key Benefits |

|---|---|

| Process Efficiency | Consolidates steps into one automated cycle, reducing cycle times and handling |

| Quality Improvement | Ensures homogeneous case hardening, minimizes distortion, and provides consistent results |

| Operational Savings | Eliminates post-processing, lowers environmental impact, and enhances safety |

| Versatility | Supports multiple thermal processes like annealing and sintering for greater ROI |

Ready to transform your lab's efficiency with advanced vacuum furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to offer high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering superior performance and cost savings. Contact us today to discuss how we can optimize your carburizing processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion