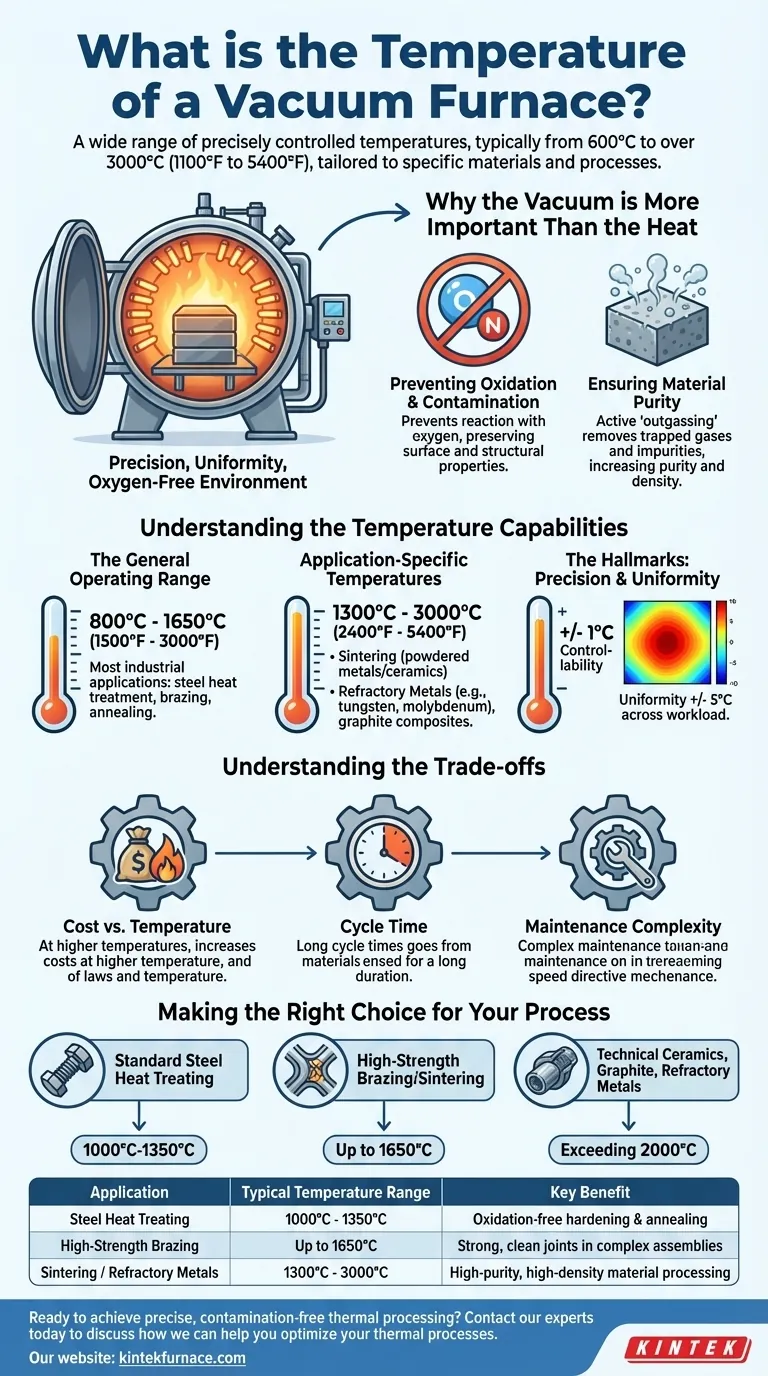

At a glance, a vacuum furnace operates at a wide range of precisely controlled temperatures, typically from 600°C to over 3000°C (1100°F to 5400°F). This range is not arbitrary; the exact temperature is a critical variable tailored to the specific material and the desired heat treatment process, such as hardening, brazing, or sintering.

The key takeaway is not a single temperature, but the furnace's ability to achieve exceptionally uniform and stable heat in an oxygen-free environment. The vacuum is what prevents oxidation and contamination, allowing for high-purity processing that is impossible in a conventional furnace.

Why the Vacuum is More Important Than the Heat

Before discussing temperature, it is essential to understand the primary function of the vacuum. The vacuum atmosphere is what defines the furnace's capability.

Preventing Oxidation and Contamination

At high temperatures, most materials—especially metals—react readily with oxygen and other atmospheric gases. This reaction, known as oxidation, can degrade the material's surface and structural properties.

A vacuum furnace works by pumping out these reactive gases before the heating cycle begins. This creates an inert environment, ensuring the material's chemistry remains pure and its surface bright and clean.

Ensuring Material Purity

The vacuum does more than just remove the surrounding atmosphere. As the material heats up, the low-pressure environment actively pulls trapped gases and other volatile impurities out from within the material itself, a process called outgassing. This significantly increases the final purity and density of the component.

Understanding the Temperature Capabilities

While the vacuum creates the necessary environment, temperature is the tool that drives the material's transformation. The required temperature is dictated entirely by the process.

The General Operating Range

Most commercial vacuum furnaces operate in a range of 800°C to 1650°C (1500°F to 3000°F). This covers the vast majority of industrial applications, including the heat treatment of steel alloys, brazing of complex assemblies, and annealing of sensitive components.

Application-Specific Temperatures

Certain advanced processes demand far more extreme temperatures.

- Sintering of powdered metals or ceramics often requires temperatures from 1300°C up to 2200°C.

- Processing refractory metals (like tungsten or molybdenum) or advanced graphite composites requires specialized furnaces that can exceed 2000°C and reach as high as 3000°C (5400°F).

The Hallmarks: Precision and Uniformity

A defining characteristic of a quality vacuum furnace is not just its maximum temperature, but its ability to control it precisely.

Modern systems offer exceptional temperature uniformity, often within +/- 5°C across the entire workload. Furthermore, the controllability of the set point can be as fine as +/- 1°C, ensuring the process is repeatable and reliable.

Understanding the Trade-offs

The exceptional capabilities of a vacuum furnace come with inherent complexities and trade-offs that are important to recognize.

Cost vs. Temperature

There is a direct and steep correlation between a furnace's maximum temperature and its cost. Furnaces operating above ~1400°C require graphite-based heating elements and insulation, while those exceeding 2000°C may need exotic refractory metals, dramatically increasing procurement and maintenance expenses.

Cycle Time

Vacuum furnace processing is not a rapid operation. Achieving a high vacuum can take a significant amount of time, as can the controlled heating and cooling ramps required for a successful cycle. The total cycle time can span many hours, or even days for very large loads.

Maintenance Complexity

High-vacuum pumps, sophisticated control systems, and high-temperature heating elements are complex components. They demand specialized knowledge for routine maintenance and repair to ensure the integrity of the vacuum and the accuracy of the thermal processing.

Making the Right Choice for Your Process

Selecting a vacuum furnace begins with a clear understanding of your material and processing goals. The temperature is a result of that need, not the starting point.

- If your primary focus is standard steel heat treating (hardening, annealing): A furnace in the 1000°C to 1350°C (1832°F to 2400°F) range is typically sufficient and cost-effective.

- If your primary focus is high-strength brazing or sintering common alloys: You will likely need a furnace capable of reaching 1650°C (3000°F) to handle a wider variety of materials and filler metals.

- If your primary focus is processing technical ceramics, graphite, or refractory metals: You must look at specialized high-temperature furnaces that can exceed 2000°C (3632°F) to meet the unique demands of these advanced materials.

Ultimately, choosing a vacuum furnace is about matching the precise thermal and atmospheric requirements of your material to achieve the desired outcome.

Summary Table:

| Application | Typical Temperature Range | Key Benefit |

|---|---|---|

| Steel Heat Treating | 1000°C - 1350°C (1832°F - 2400°F) | Oxidation-free hardening & annealing |

| High-Strength Brazing | Up to 1650°C (3000°F) | Strong, clean joints in complex assemblies |

| Sintering / Refractory Metals | 1300°C - 3000°C (2400°F - 5400°F) | High-purity, high-density material processing |

Ready to achieve precise, contamination-free thermal processing?

KINTEK's advanced vacuum furnace solutions combine exceptional R&D and in-house manufacturing to deliver the exact temperature control and vacuum environment your lab requires. Whether you need a standard Muffle or Tube Furnace or a highly customized high-temperature Vacuum & Atmosphere Furnace for sintering or CVD/PECVD applications, our deep customization capabilities ensure a perfect fit for your unique experimental needs.

Contact our experts today to discuss how we can help you optimize your thermal processes.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes