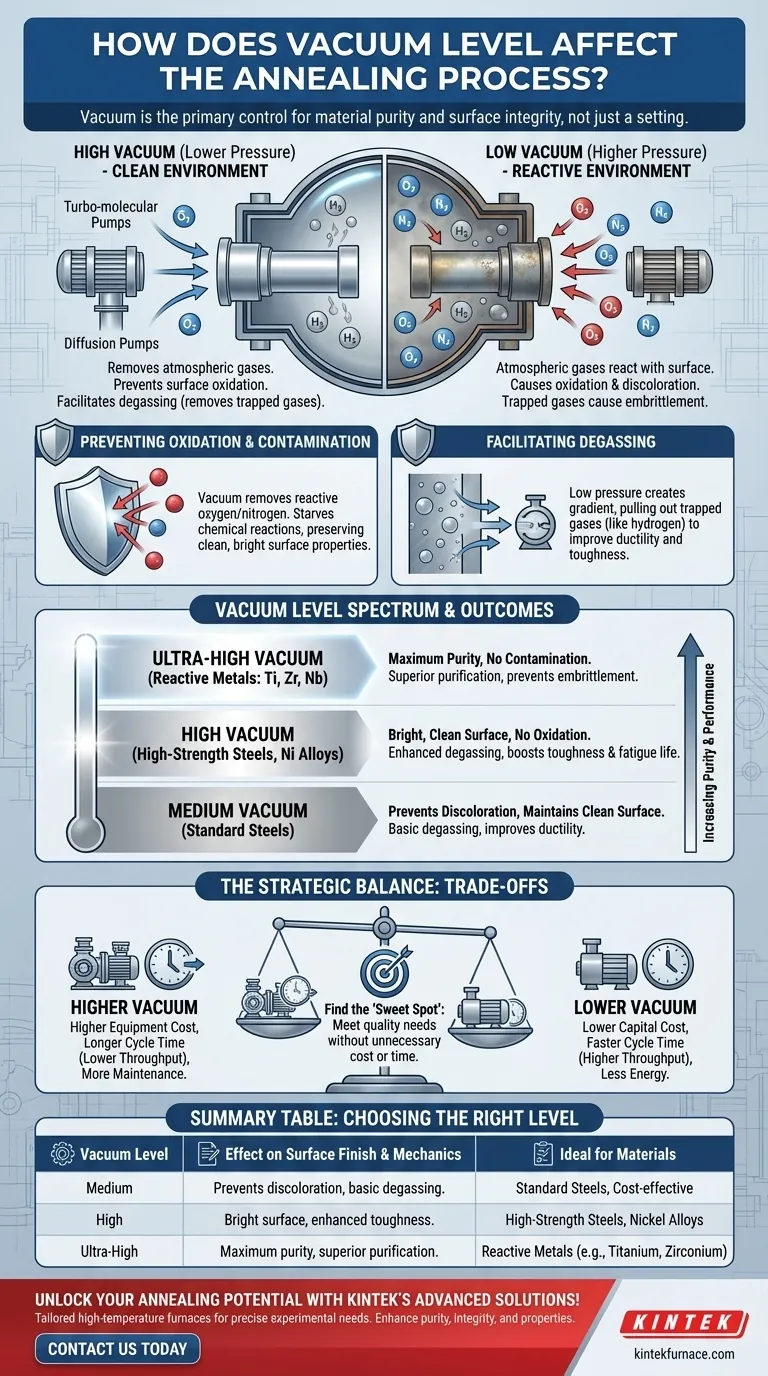

In vacuum annealing, the level of vacuum is not just a setting—it is the primary control for material purity and surface integrity. A higher vacuum (lower pressure) creates a cleaner environment by removing atmospheric gases like oxygen and nitrogen. This directly prevents surface oxidation and discoloration during heating while also facilitating the removal of trapped gases from within the material, a process known as degassing, which is critical for improving ductility and overall performance.

The core function of the vacuum is to create an environment where the heated material is less likely to react with its surroundings. A higher vacuum level doesn't just protect the surface; it actively purifies the material by pulling out trapped gases, which is critical for achieving optimal mechanical properties and performance stability.

The Fundamental Purpose of Vacuum in Annealing

To understand the effect of the vacuum level, you must first understand its two primary functions: preventing external contamination and enabling internal purification.

Preventing Oxidation and Contamination

When heated to annealing temperatures, most metals become highly reactive. If exposed to air, even in small amounts, oxygen will rapidly bond with the metal's surface, forming a discolored and often brittle oxide layer.

A vacuum furnace works by physically removing the majority of gas molecules—primarily oxygen and nitrogen—from the chamber. The "level" of the vacuum simply refers to how few of these reactive molecules are left.

By minimizing the partial pressure of these gases, you starve the chemical reaction of the fuel it needs, preserving the material's clean, bright surface and its inherent properties.

Facilitating Degassing

Many materials contain dissolved gases like hydrogen or microscopic gas pockets trapped during casting or manufacturing. These internal impurities can cause embrittlement and create weak points within the material's structure.

Heating the material gives these trapped gas atoms the energy to move. The low-pressure environment of the vacuum creates a strong pressure gradient between the inside of the material and the chamber, effectively pulling these unwanted gases out. This purification step is essential for enhancing ductility and fatigue life.

How Vacuum Level Dictates Process Outcomes

The specific vacuum level you choose has a direct and predictable impact on the final quality of the part. A lower-quality vacuum may be acceptable for some materials, while it would be catastrophic for others.

Impact on Surface Finish

The most visible effect of the vacuum level is the surface finish. A poor vacuum will result in discoloration or a dull, matte finish due to microscopic surface oxidation.

A high-quality vacuum, however, results in a bright, clean surface. This is not merely cosmetic; a clean surface is critical for subsequent processes like brazing, welding, or applying specialized coatings that require a perfectly pure substrate to bond correctly.

Impact on Mechanical Properties

For performance-critical applications, the invisible effects are more important. By enabling effective degassing, a high vacuum level directly improves the material's ductility and toughness.

Removing interstitial elements like hydrogen and oxygen prevents internal defects and reduces brittleness, allowing the material to deform under stress rather than fracturing prematurely. This is especially critical for metals used in aerospace, medical, and high-stress industrial applications.

Material-Specific Requirements

The necessary vacuum level is highly dependent on the material's reactivity.

A common tool steel may only require a medium vacuum to prevent significant oxidation. In contrast, highly reactive metals like titanium, zirconium, and niobium require a very high or ultra-high vacuum. Even trace amounts of oxygen or nitrogen can diffuse into these materials at high temperatures, irreversibly compromising their mechanical properties.

Understanding the Trade-offs and Limitations

Choosing the highest possible vacuum is not always the best strategy. The decision involves a balance of cost, time, and material requirements.

The Cost of Higher Vacuum

Achieving higher vacuum levels requires more sophisticated and expensive equipment. A furnace capable of reaching a medium vacuum may use relatively simple mechanical pumps.

A high-vacuum system, however, requires additional turbo-molecular, diffusion, or cryogenic pumps. These systems have higher capital costs, require more maintenance, and consume more energy.

Cycle Time and Throughput

Pumping a chamber down to a high vacuum takes significantly longer than reaching a medium vacuum. This increased pump-down time extends the total cycle time for each batch.

For high-volume production of non-critical parts, this reduction in throughput can make high-vacuum annealing economically unviable. The goal is to find the "sweet spot" that meets quality requirements without unnecessarily slowing down production.

The Law of Diminishing Returns

For a standard, non-reactive alloy, moving from a medium vacuum (e.g., 10⁻³ torr) to a high vacuum (10⁻⁶ torr) may yield no measurable improvement in mechanical properties or visual appearance.

In these cases, investing in a higher vacuum level adds cost and time for no tangible benefit. The process must be engineered to be sufficient, not excessive.

Choosing the Right Vacuum Level for Your Application

The optimal vacuum level is a balance between the material's metallurgical needs, the desired final properties, and operational efficiency. Use the following guidelines to make an informed decision.

- If your primary focus is surface cosmetics and preventing discoloration: A medium vacuum that effectively removes the bulk of oxygen is often sufficient for less reactive alloys like standard steels.

- If your primary focus is maximizing ductility and performance in sensitive materials: A high vacuum is necessary to facilitate thorough degassing and prevent even trace amounts of contamination in high-strength steels or nickel-based alloys.

- If you are working with highly reactive metals (e.g., titanium, niobium): You must use a high or ultra-high vacuum system, as process integrity is paramount and any contamination will compromise the material's fundamental properties.

- If your primary focus is cost-efficiency for general-purpose annealing: Use the lowest vacuum level that meets the minimum quality specification for your material to minimize cycle time and energy consumption.

Ultimately, treating the vacuum level as a critical process parameter, just like temperature and time, is the key to achieving consistent and reliable results in annealing.

Summary Table:

| Vacuum Level | Effect on Surface Finish | Effect on Mechanical Properties | Ideal for Materials |

|---|---|---|---|

| Medium | Prevents discoloration, maintains clean surface | Basic degassing, improves ductility | Standard steels, cost-effective applications |

| High | Bright, clean surface, no oxidation | Enhanced degassing, boosts toughness and fatigue life | High-strength steels, nickel alloys |

| Ultra-High | Maximum purity, no contamination | Superior purification, prevents embrittlement | Reactive metals (e.g., titanium, zirconium) |

Unlock the full potential of your annealing process with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing material purity, surface integrity, and mechanical properties. Don't let suboptimal vacuum levels compromise your results—contact us today to discuss how our solutions can elevate your annealing operations and drive efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability