At its core, low pressure carburizing (LPC) fundamentally improves metal quality by eliminating the variable of oxygen. By conducting the heat treatment process in a vacuum, LPC prevents the surface and sub-surface oxidation defects that are inherent risks in traditional atmospheric carburizing, resulting in a metallurgically cleaner, stronger, and more predictable final component.

The crucial takeaway is that while traditional methods fight to control oxygen, low pressure carburizing removes it entirely. This single difference prevents a cascade of potential defects, leading directly to superior mechanical properties and part-to-part consistency.

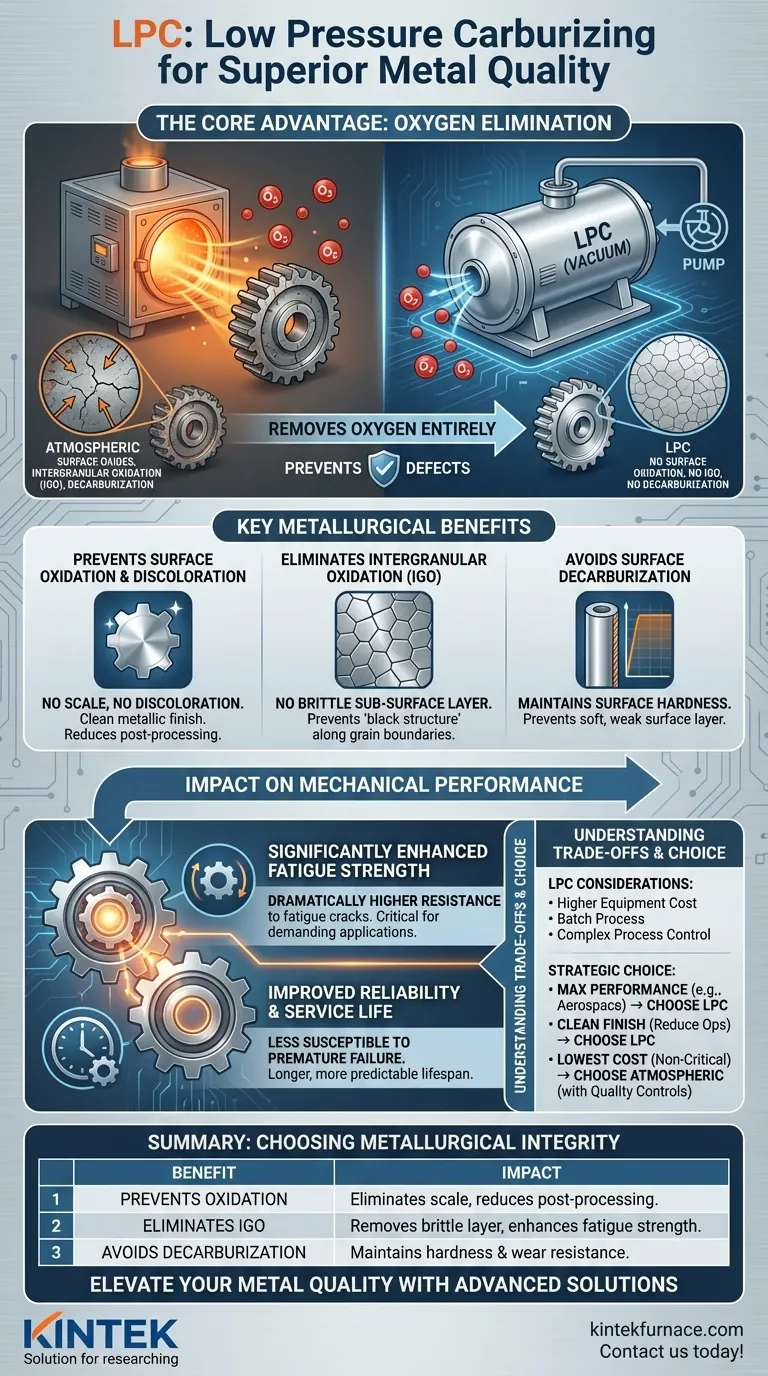

The Core Advantage: Eliminating Oxygen from the Equation

The primary benefits of LPC all stem from its oxygen-free vacuum environment. This isn't just a minor process tweak; it represents a fundamental shift in how the steel's surface is modified.

Preventing Surface Oxidation and Discoloration

In traditional gas carburizing, parts are exposed to an atmosphere that, even when "controlled," contains oxygen. This inevitably leads to the formation of surface oxides.

LPC physically removes the air from the chamber before introducing the carburizing gas. This complete absence of oxygen means no scale or discoloration can form, leaving parts with a clean, bright metallic finish straight out of the furnace. This often eliminates the need for costly post-processing steps like shot blasting or chemical cleaning.

Eliminating Intergranular Oxidation (IGO)

This is the most critical metallurgical benefit. In atmospheric processes, oxygen atoms can diffuse into the steel along its grain boundaries, reacting with alloying elements to form a network of microscopic oxides just below the surface.

This phenomenon, known as Intergranular Oxidation (IGO) or "black structure," creates a brittle, weakened sub-surface layer. Because LPC operates in a vacuum, there is no free oxygen to penetrate the grain boundaries. LPC completely avoids the formation of IGO.

Avoiding Surface Decarburization

Decarburization is the loss of carbon from the steel's surface, which creates a soft, weak layer that compromises wear resistance and fatigue life. It can occur in atmospheric furnaces with poor atmospheric control.

The precise control and oxygen-free environment of an LPC system prevent this loss of surface carbon, ensuring the final part achieves its designed surface hardness and case depth consistently.

The Impact on Mechanical Performance

Eliminating these oxygen-related defects is not merely an aesthetic improvement. It has a direct and significant impact on the mechanical performance and reliability of the final component.

Significantly Enhanced Fatigue Strength

IGO is the primary enemy of fatigue life. The brittle oxide networks created by IGO act as microscopic stress risers—perfect initiation points for fatigue cracks to form and propagate under cyclic loading.

By completely preventing IGO, LPC produces components with a dramatically higher fatigue strength. This is not a marginal improvement; it is a step-change in performance, critical for components in demanding applications like transmissions, bearings, and aerospace systems.

Improved Reliability and Service Life

The enhancement in fatigue strength directly translates to more reliable parts with a longer, more predictable service life.

Components treated with LPC are less susceptible to premature failure from surface-initiated cracks. This reduces warranty claims, improves product reputation, and allows for the design of lighter, more powerful systems that operate closer to their material limits.

Understanding the Trade-offs

While metallurgically superior, LPC is not the universal solution for all applications. An objective evaluation requires acknowledging its operational and economic differences from traditional methods.

Higher Initial Equipment Cost

Vacuum furnaces and their associated pumping systems represent a significantly higher capital investment compared to standard atmospheric carburizing furnaces.

Batch Processing Nature

LPC is inherently a batch process. While modern systems are highly efficient, they may not match the continuous throughput of some large-scale atmospheric furnace lines, which can be a consideration for very high-volume, low-margin parts.

Process Control Complexity

Though highly automated, LPC systems require skilled technicians for operation and maintenance. The high-vacuum technology and precise gas control systems are more complex than their atmospheric counterparts.

Making the Right Choice for Your Goal

The decision between low pressure and traditional carburizing is a strategic choice based on your specific performance requirements and business goals.

- If your primary focus is maximum performance and reliability: LPC is the definitive choice for critical components where fatigue failure is not an option, such as in aerospace, motorsports, and high-performance industrial gearing.

- If your primary focus is a clean finish and reducing post-processing: LPC delivers clean, bright parts that eliminate secondary operations, saving time and labor in your production flow.

- If your primary focus is minimizing per-part cost for non-critical components: Traditional gas carburizing remains a viable and economical option, provided you have robust quality controls to manage the inherent risks of oxidation.

Ultimately, selecting low pressure carburizing is a decision to prioritize metallurgical integrity and predictable performance over lower initial process cost.

Summary Table:

| Benefit | Impact on Metal Quality |

|---|---|

| Prevents Surface Oxidation | Eliminates scale and discoloration, reducing post-processing needs |

| Eliminates Intergranular Oxidation (IGO) | Removes brittle sub-surface layer, enhancing fatigue strength |

| Avoids Surface Decarburization | Maintains surface hardness and wear resistance consistently |

| Improves Mechanical Performance | Increases reliability and service life for critical components |

Ready to elevate your metal quality with advanced heat treatment solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're in aerospace, motorsports, or industrial applications, our low pressure carburizing expertise can help you achieve superior fatigue strength and reliability. Contact us today to discuss how we can optimize your processes and deliver consistent, high-performance results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control