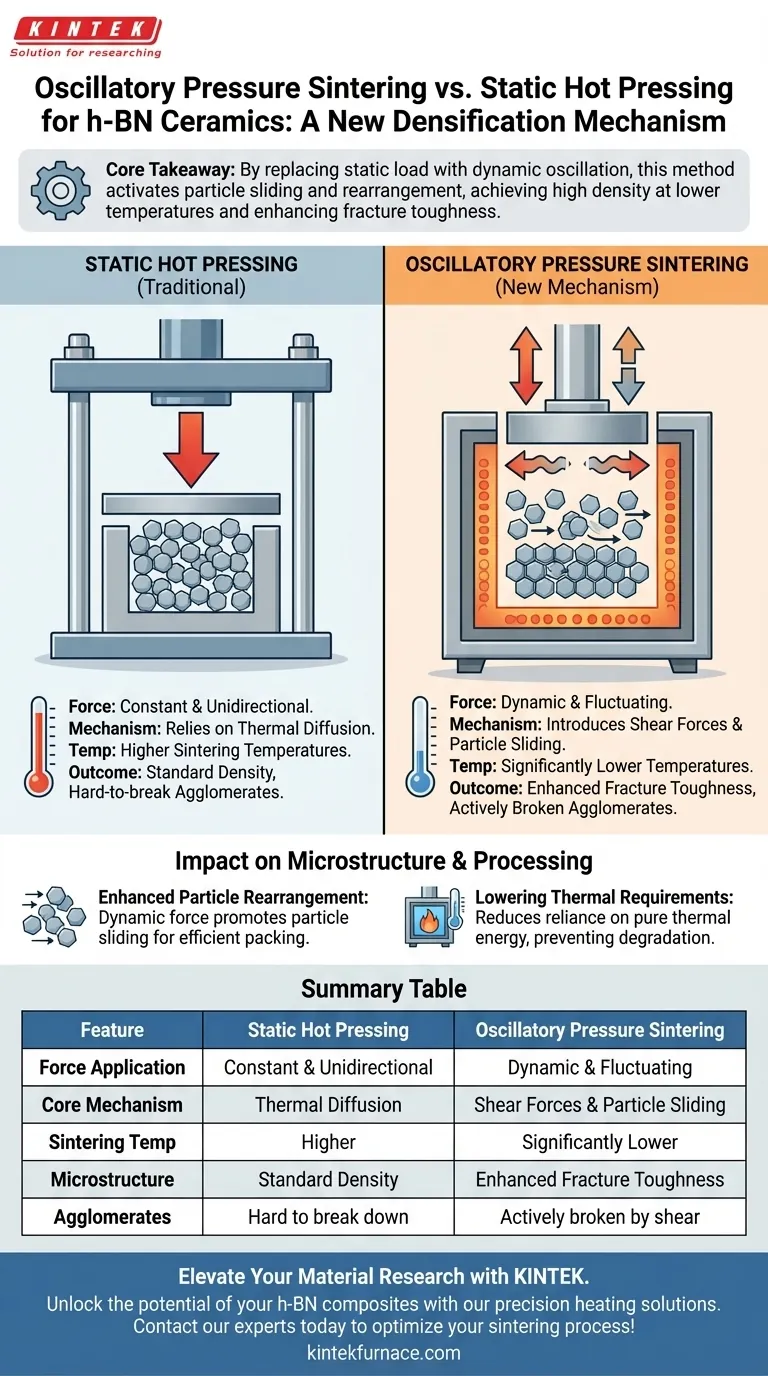

Oscillatory pressure sintering introduces a dynamic, fluctuating force that fundamentally changes how ceramic particles interact during densification. Unlike traditional static hot pressing, which relies on constant unidirectional pressure, this mechanism utilizes oscillatory energy to generate internal shear forces that actively break down agglomerates.

Core Takeaway: By replacing static load with dynamic oscillation, this method activates particle sliding and rearrangement mechanisms that static pressure cannot trigger. This allows hexagonal boron nitride (h-BN) composites to achieve high density at significantly lower temperatures while forming specific microstructures that enhance fracture toughness.

The Mechanics of Oscillatory Pressure

Dynamic vs. Static Force Application

Traditional hot press equipment applies a static, constant load. This relies heavily on thermal energy to induce diffusion and densification.

In contrast, an oscillatory pressure sintering furnace applies a dynamically changing pressure. This constant fluctuation creates a mechanical environment where particles are kept in motion relative to one another.

The Critical Role of Shear Forces

The most significant new mechanism introduced is the generation of shear forces.

While static pressing compresses particles, oscillatory pressure induces shear. This force helps eliminate pores that might otherwise remain trapped under static load, leading to a more solid and uniform composite.

Impact on Microstructure and Processing

Enhanced Particle Rearrangement

The dynamic force promotes particle sliding.

Rather than simply being crushed together, the particles are encouraged to slide and rearrange into the most efficient packing configuration. This physical rearrangement is a key driver for achieving high densification.

Lowering Thermal Requirements

Because the mechanical forces (shear and rearrangement) are more active, the process relies less on pure thermal energy.

Consequently, h-BN composites can achieve the required density at lower sintering temperatures. This prevents potential degradation associated with excessive heat while still ensuring a robust final product.

Understanding the Operational Trade-offs

Process Complexity vs. Simplicity

While the primary reference highlights the benefits of oscillatory pressure, it is important to understand the operational distinction.

Static hot pressing is a simpler, linear application of force. It requires higher temperatures to achieve similar results because it lacks the mechanical aid of shear forces.

Oscillatory pressure introduces mechanical complexity to the sintering cycle. However, this complexity is the specific trade-off required to access microstructural toughening and thermal efficiency that static methods cannot provide.

Making the Right Choice for Your Goal

To determine if oscillatory pressure sintering is required for your h-BN application, evaluate your specific performance targets.

- If your primary focus is Maximizing Toughness: Oscillatory pressure is essential, as the shear forces help form specific microstructures that enhance the material's mechanical resistance.

- If your primary focus is Reducing Thermal Budget: This method allows you to achieve high density at lower temperatures, preserving material properties that might degrade under higher heat.

Dynamic pressure transforms the sintering process from a passive thermal event into an active mechanical one.

Summary Table:

| Feature | Static Hot Pressing | Oscillatory Pressure Sintering |

|---|---|---|

| Force Application | Constant & Unidirectional | Dynamic & Fluctuating |

| Core Mechanism | Thermal Diffusion | Shear Forces & Particle Sliding |

| Sintering Temp | Higher | Significantly Lower |

| Microstructure | Standard Density | Enhanced Fracture Toughness |

| Agglomerates | Hard to break down | Actively broken by shear |

Elevate Your Material Research with KINTEK

Unlock the full potential of your h-BN composites and advanced ceramics with KINTEK’s precision heating solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces, all fully customizable to meet your unique project requirements.

Whether you need to enhance fracture toughness or reduce your thermal budget, our specialized equipment provides the control and efficiency your lab demands.

Ready to optimize your sintering process? Contact our experts today to find the perfect solution for your needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the core functions of vacuum devices in Polymer Impregnation Method? Enhance Deep Structural Reinforcement

- How does a modern pressure sintering furnace operate? Unlock High-Density Materials with Precision

- Why is a high-vacuum system required for PVD of doped hydroxyapatite? Achieve High-Purity Biomedical Coatings

- What role does a vacuum annealing furnace play in Bi4I4 single crystals? Master Precise Fermi Level Engineering

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What temperature is vacuum brazing? Achieve Strong, Flux-Free Joints in a Controlled Environment

- How does a vacuum drying oven ensure efficient encapsulation? Master Vacuum Impregnation for Phase Change Materials

- What are the core functions of a vacuum thermal reduction furnace? Efficiently Extract Pure Magnesium