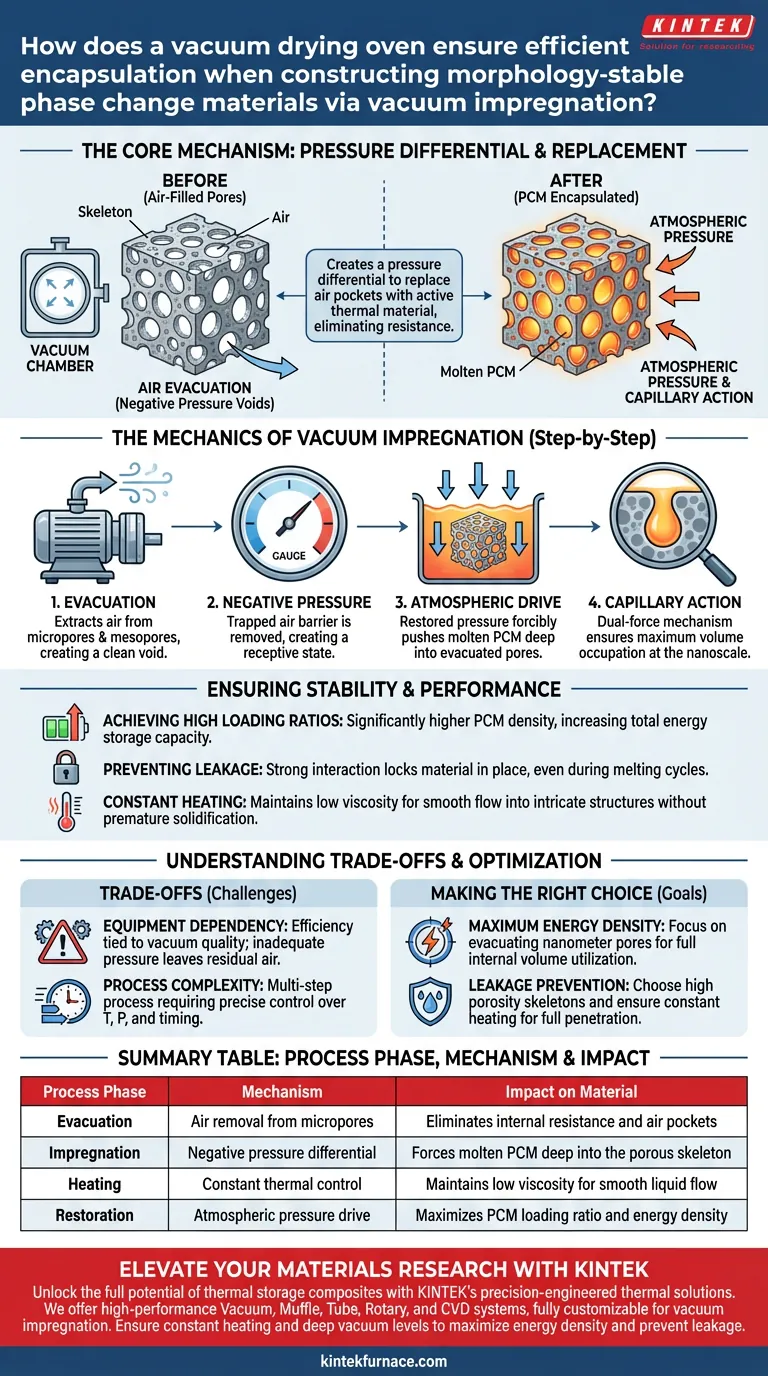

A vacuum drying oven ensures efficient encapsulation by creating a pressure differential that physically forces liquid phase change materials (PCMs) into the microscopic structures of a porous skeleton. By first evacuating air from the support material's pores, the oven eliminates internal resistance, allowing atmospheric pressure and capillary action to drive the molten PCM deep into nanometer-sized voids once pressure is restored.

The core mechanism of vacuum impregnation is the replacement of air pockets with active thermal material. This process utilizes the synergy of negative pressure voids and the restoring force of atmospheric pressure to achieve maximum material density and preventing leakage.

The Mechanics of Vacuum Impregnation

Evacuation of the Support Skeleton

The process begins by placing a porous support material, such as biomass carbon or minerals, into the vacuum oven. The system extracts air trapped within the material's micropores and mesopores, creating a clean void.

Creating a Negative Pressure Environment

Removing the air creates a state of negative pressure inside the skeleton structures. This step is critical because trapped air acts as a barrier that physically blocks liquids from entering small voids.

The Driving Force of Atmospheric Pressure

Once the skeleton is submerged in molten PCM (like paraffin or polyethylene glycol), the system restores atmospheric pressure. This external pressure creates a powerful differential, forcibly pushing the liquid PCM into the evacuated pores.

Capillary Action at the Nanoscale

While atmospheric pressure initiates the fill, capillary forces assist in drawing the liquid into nanometer-sized pores. This dual-force mechanism ensures the PCM occupies the maximum available volume within the support structure.

Ensuring Stability and Performance

Achieving High Loading Ratios

Vacuum impregnation results in a composite with a significantly higher density of PCM compared to simple immersion methods. This maximizes the loading ratio, directly increasing the total energy storage capacity of the final material.

Preventing Leakage

Deep infiltration promotes a strong interaction between the PCM core and the porous framework. This structural integration effectively locks the material in place, preventing leakage even when the PCM melts during thermal cycling.

The Necessity of Constant Heating

The vacuum oven provides constant heating throughout the impregnation process. This maintains the PCM in a low-viscosity liquid state, ensuring it flows smoothly into the intricate pore structure without premature solidification.

Understanding the Trade-offs

Equipment Dependency

The efficiency of encapsulation is directly tied to the quality of the vacuum generated. Inadequate negative pressure leaves residual air pockets, which permanently reduces the material's thermal capacity.

Process Complexity

Compared to surface coating or simple mixing, vacuum impregnation is a multi-step process. It requires precise control over temperature, vacuum levels, and repressurization timing to ensure the skeleton is not damaged while maximizing fill.

Making the Right Choice for Your Goal

To optimize the construction of morphology-stable PCMs, consider your specific performance targets:

- If your primary focus is maximum energy density: Ensure your vacuum system can evacuate nanometer-sized pores to utilize the full internal volume of the support skeleton.

- If your primary focus is leakage prevention: Select a support skeleton with high porosity and maintain constant heating to guarantee the PCM fully penetrates and bonds with the inner framework.

The vacuum drying oven transforms a porous skeleton from a passive carrier into an active, high-efficiency thermal storage composite.

Summary Table:

| Process Phase | Mechanism | Impact on Material |

|---|---|---|

| Evacuation | Air removal from micropores | Eliminates internal resistance and air pockets |

| Impregnation | Negative pressure differential | Forces molten PCM deep into the porous skeleton |

| Heating | Constant thermal control | Maintains low viscosity for smooth liquid flow |

| Restoration | Atmospheric pressure drive | Maximizes PCM loading ratio and energy density |

Elevate Your Materials Research with KINTEK

Unlock the full potential of your thermal storage composites with KINTEK’s precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems, all fully customizable to meet the rigorous demands of vacuum impregnation and morphology-stable material construction.

Whether you are scaling up production or refining nanometer-scale voids, our laboratory high-temp furnaces ensure the constant heating and deep vacuum levels necessary to prevent leakage and maximize energy density. Contact us today to find the perfect system for your lab!

Visual Guide

References

- Yuan Jia, Yushi Liu. Recent advances in energy storage and applications of form‐stable phase change materials with recyclable skeleton. DOI: 10.1002/cnl2.117

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What is the function of annealing furnaces in the manufacturing process of Indium Zinc Oxide (IZO) Thin Film Transistors (TFTs)? | Unlock High-Performance Electronics

- Why are inert gases necessary in vacuum furnaces? Unlock Precision in Heat Treatment

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- What role do vacuum annealing furnaces play in optical material processing? Enhance Clarity and Performance for Your Optics

- What are the advantages of using SSRs over contactors for heating control? Achieve Superior Precision in Vacuum Distillation

- How are vacuum experimental furnaces used in research and laboratory settings? Unlock Precision in Materials Science

- What are the environmental advantages of vacuum-environment furnaces for coking? Learn how to eliminate leakage.

- What is the contamination of the vacuum furnace? Master Prevention for Flawless Results