In optical material processing, vacuum annealing furnaces serve a critical function: they refine a material's internal structure and surface to achieve maximum optical performance. Their primary roles are to eliminate internal stress in components like optical fibers, which improves signal transmission, and to enhance the light transmittance and uniformity of materials used for high-precision lenses. This is all accomplished within a highly controlled, contaminant-free environment.

The fundamental purpose of using a vacuum is to create a pristine processing environment. By removing reactive gases like oxygen, the furnace prevents surface degradation and allows the heat treatment to purely address the material's internal structure, relieving stress and improving uniformity—a non-negotiable requirement for high-performance optics.

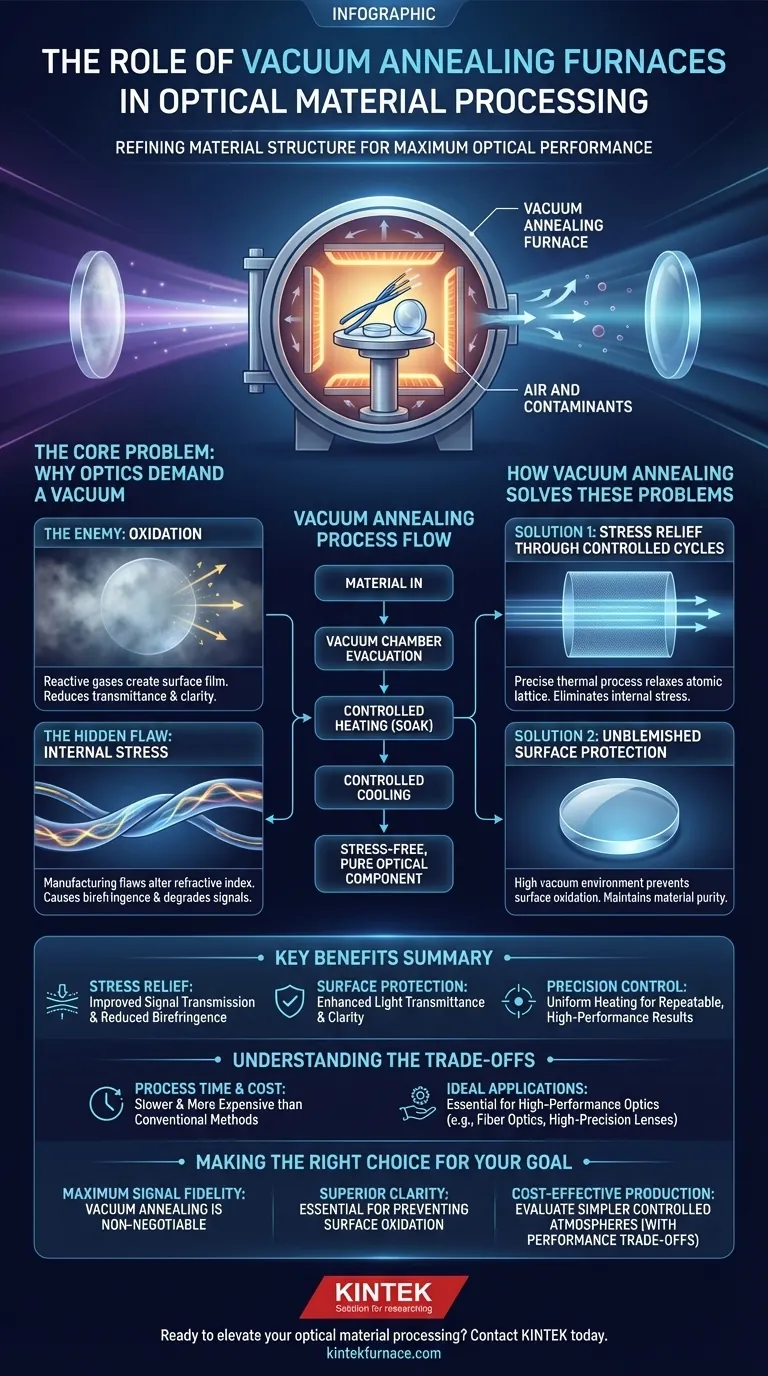

The Core Problem: Why Optics Demand a Vacuum

The extreme precision required in optical applications makes materials highly sensitive to imperfections. A vacuum environment is not a luxury; it is a direct solution to the core problems that degrade optical quality.

The Enemy of Clarity: Oxidation

At the high temperatures required for annealing, materials readily react with oxygen in the air. This process, oxidation, creates a thin film on the material's surface.

This oxide layer scatters and absorbs light, which severely reduces the transmittance and clarity of a lens or the efficiency of a fiber. A vacuum furnace eliminates this issue by removing virtually all oxygen before heating begins.

The Hidden Flaw: Internal Stress

Manufacturing processes, such as drawing optical fiber or molding a lens, introduce internal mechanical stress into the material's atomic structure.

This stress is a critical flaw because it can alter the material's refractive index in unpredictable ways, causing effects like birefringence (double refraction) that distort images or degrade signal quality in fiber optics.

The Goal: Predictable Performance

An optical system is designed with the assumption that light will pass through its components in a perfectly predictable manner. Any material impurity, surface defect, or structural non-uniformity introduces variables that scatter, absorb, or alter the path of light, compromising the entire system's performance.

How Vacuum Annealing Solves These Problems

A vacuum annealing furnace provides a multi-faceted solution, using a controlled thermal cycle in an inert environment to perfect the optical material.

Stress Relief Through Controlled Cycles

The core of annealing is a precise thermal process. The material is heated to a specific temperature below its melting point, held there for a period (a "soak"), and then cooled at a carefully controlled rate.

This process gives the material's atomic lattice enough energy to relax and rearrange into a more stable, lower-energy state. The result is a significant reduction or complete elimination of internal stress.

Ensuring an Unblemished Surface

By performing the annealing cycle in a high vacuum, the furnace guarantees the material never comes into contact with reactive gases.

This prevents surface oxidation and ensures the material exits the process with the same purity and surface quality it had going in, preserving its inherent optical properties.

Precision Control Over Temperature

Modern vacuum furnaces offer exceptional control over heating rates, temperature stability during the soak, and cooling profiles. This precision is vital for achieving repeatable results and tailoring the final properties for different types of optical glass, crystals, or fibers.

Understanding the Trade-offs

While incredibly effective, vacuum annealing is a specialized process with practical considerations that make it unsuitable for every application.

Process Time and Throughput

Vacuum processes are inherently slower than treatments in atmospheric furnaces. The time required to pump the chamber down to a high vacuum can be significant, potentially creating a bottleneck in high-volume manufacturing.

Equipment Cost and Complexity

Vacuum furnaces are sophisticated machines that are more expensive to purchase, operate, and maintain than conventional ovens. They require robust vacuum pumps, precise seals, and advanced control systems, all of which represent a significant investment.

Not a Universal Solution

The high cost and lower throughput mean vacuum annealing is typically reserved for applications where performance is paramount. For lower-grade optical components with wider performance tolerances, a less expensive controlled atmosphere (like nitrogen) may provide a "good enough" result.

Making the Right Choice for Your Goal

The decision to use vacuum annealing depends entirely on the required performance level of your optical component.

- If your primary focus is maximum signal fidelity in fiber optics: Vacuum annealing is non-negotiable to eliminate stress-induced signal degradation and ensure low attenuation.

- If your primary focus is superior clarity and transmittance in lenses or windows: A vacuum environment is essential to prevent the surface oxidation that would otherwise scatter and absorb light.

- If your primary focus is cost-effective production of non-critical components: You may evaluate whether a simpler controlled atmosphere provides sufficient protection, but this will always come with a performance trade-off compared to a true vacuum.

Ultimately, employing a vacuum furnace is an investment in material purity and structural integrity, ensuring your optical components perform exactly as designed.

Summary Table:

| Role | Key Benefit |

|---|---|

| Stress Relief | Eliminates internal stress for improved signal transmission and reduced birefringence |

| Surface Protection | Prevents oxidation in a contaminant-free environment, enhancing light transmittance |

| Precision Control | Enables uniform heating and cooling for repeatable, high-performance results |

Ready to elevate your optical material processing with precision and purity? Contact KINTEK today to explore our advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs, ensuring superior clarity and performance for your laboratory applications.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process