At its core, a vacuum or protective atmosphere reduces oxidation by physically isolating the molten metal from oxygen. By either removing the air (vacuum) or replacing it with a non-reactive gas (protective atmosphere), these methods eliminate a key ingredient required for the chemical reaction of oxidation to occur, especially at the high temperatures that make metals highly reactive.

The high temperatures required to melt or process metal also dramatically accelerate its reaction with oxygen. Controlling the atmosphere is not a minor process tweak; it is the fundamental strategy for preventing the formation of strength-degrading oxide inclusions and ensuring the final product's integrity.

The Fundamental Problem: Heat, Metal, and Oxygen

Why High Temperatures Accelerate Oxidation

Heat is a form of energy. When a metal is heated, its atoms vibrate more rapidly, making them significantly more reactive.

This added energy easily overcomes the threshold needed for the metal to react with any available oxygen, a process known as oxidation. A molten state is the extreme of this, presenting a highly reactive liquid surface.

The Formation of Oxide Inclusions

Oxidation is a chemical reaction between a metal and oxygen, forming a new compound called a metal oxide. You see this in everyday life as rust on iron.

When this happens in molten metal, these oxides can become trapped as the metal cools and solidifies. These trapped impurities are known as oxide inclusions.

The Impact of Oxides on Metal Integrity

Oxide inclusions are essentially tiny, brittle, ceramic-like particles embedded within the metallic structure. They do not bond well with the surrounding metal.

These inclusions act as internal stress points, creating microscopic weak spots where cracks can begin. This severely degrades critical mechanical properties like strength, ductility, and fatigue resistance, while also impairing the metal's natural corrosion resistance.

The Two Primary Solutions

To prevent oxidation, you must control the atmosphere around the hot metal. This is accomplished in two primary ways: removal or displacement.

How a Vacuum Works: The Removal Strategy

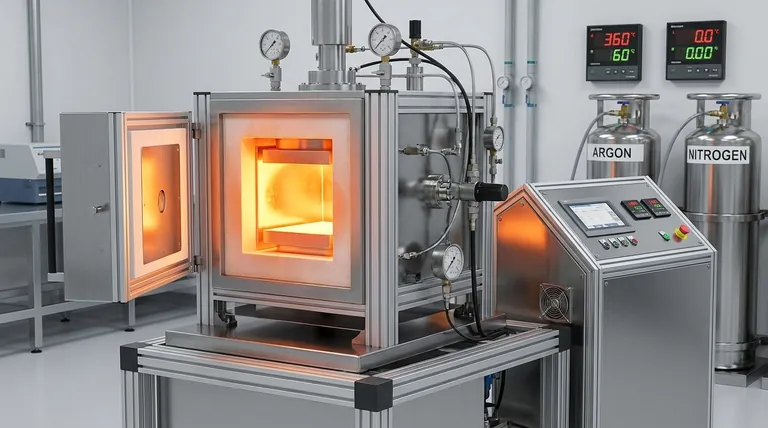

A vacuum furnace uses pumps to physically remove air—and therefore oxygen—from a sealed chamber. This starves the oxidation reaction of its necessary fuel.

By creating an environment with extremely low pressure, the number of oxygen molecules available to collide with and react with the metal surface is reduced to a negligible level. This is the most effective way to achieve a truly oxygen-free environment.

How a Protective Atmosphere Works: The Displacement Strategy

This strategy involves flooding the chamber with a gas that will not react with the metal, typically an inert gas like Argon or sometimes Nitrogen.

This inert gas displaces the regular, oxygen-rich air, blanketing the molten metal and preventing oxygen from making contact with its surface. While the goal is the same, the mechanism is one of replacement rather than removal.

Understanding the Trade-offs

Choosing between a vacuum and a protective atmosphere depends on the application's specific requirements for purity, cost, and process efficiency.

Vacuum: Purity vs. Complexity

A vacuum environment offers the highest level of purity. It not only removes oxygen but also helps pull other volatile impurities and dissolved gases out of the molten metal, a process known as degassing.

However, vacuum furnaces represent a significant investment in specialized equipment. The process is typically batch-oriented and can have longer cycle times, making it more complex and costly than other methods.

Protective Atmosphere: Scalability vs. Purity

Using an inert gas atmosphere is often more cost-effective and easier to integrate into continuous manufacturing processes. It provides excellent protection for a wide range of applications like welding and brazing.

The main trade-off is that it may not achieve the absolute purity of a high vacuum. The quality of the result is dependent on the purity of the inert gas used and the ability to completely purge all oxygen from the chamber.

Making the Right Choice for Your Goal

Your decision should be driven by the end requirements of your component.

- If your primary focus is maximum material purity and performance: A vacuum environment is the superior choice, as it most effectively removes reactive gases and other volatile contaminants.

- If your primary focus is process efficiency for robust applications: A protective atmosphere of inert gas provides excellent oxidation prevention without the cost and complexity of a full vacuum.

- If you are working with highly reactive metals like titanium or aluminum: Atmospheric control is non-negotiable, and a high-purity vacuum or a precisely controlled inert gas atmosphere is essential to prevent catastrophic property degradation.

Ultimately, managing the atmosphere is managing the quality and reliability of your final metallic component.

Summary Table:

| Method | Mechanism | Key Benefits | Ideal Use Cases |

|---|---|---|---|

| Vacuum | Removes air/oxygen via pumps | Highest purity, degassing, oxygen-free environment | High-purity metals, reactive metals like titanium |

| Protective Atmosphere | Displaces air with inert gases (e.g., Argon) | Cost-effective, scalable, continuous processing | Welding, brazing, robust applications |

Upgrade your metal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions to meet your unique experimental needs, enhancing purity, strength, and efficiency. Contact us today to discuss how we can help prevent oxidation and improve your metal integrity!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure