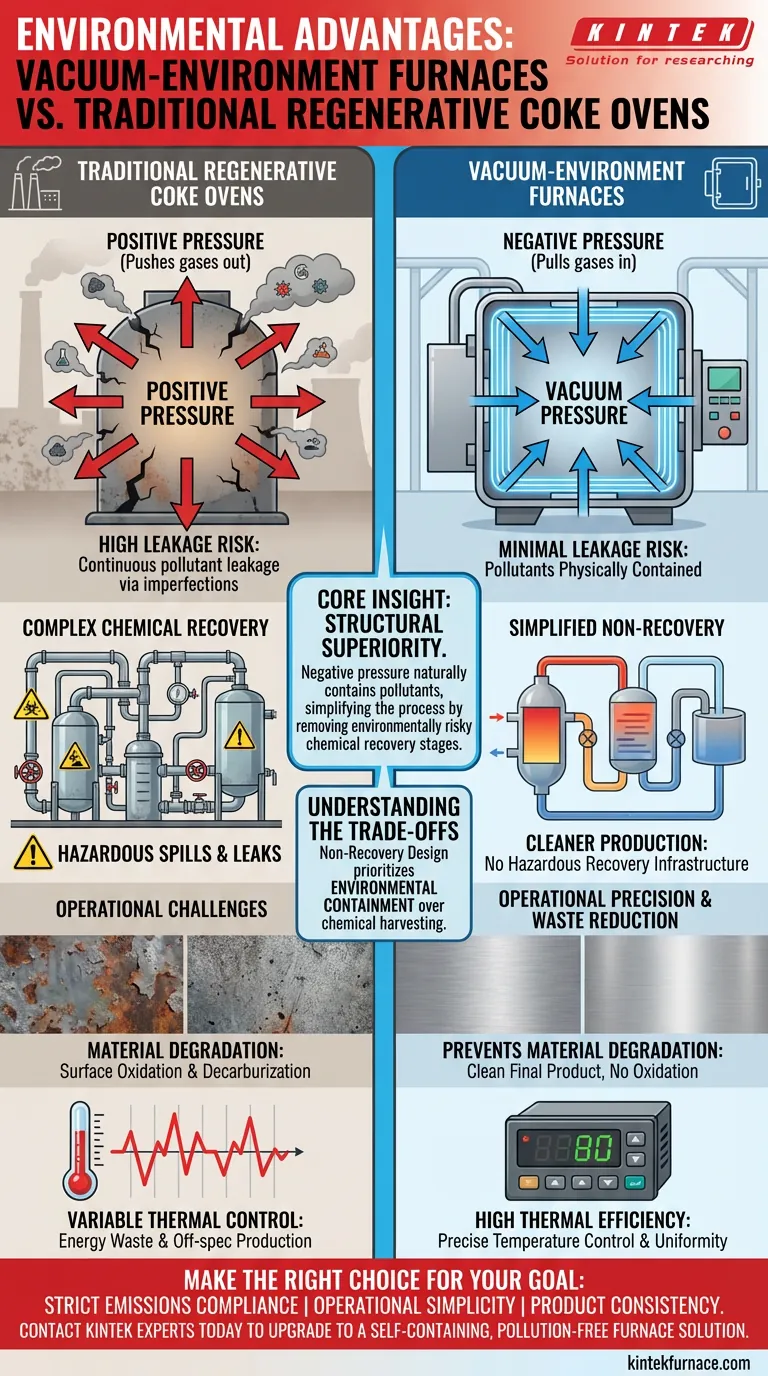

The primary environmental advantage of vacuum-environment furnaces lies in their ability to eliminate pollutant leakage through pressure differentials. By operating under negative pressure, these systems physically prevent emissions from escaping, a sharp contrast to traditional regenerative coke ovens which operate under positive pressure and are prone to leaking harmful gases. This design frequently enables a non-recovery process, removing the need for hazardous chemical recovery infrastructure.

Core Insight: The environmental superiority of vacuum furnaces is structural, not just operational. By maintaining negative pressure, they create a sealed system that naturally contains pollutants, while simultaneously simplifying the production chain to remove the environmentally risky stages of chemical byproduct recovery.

The Physics of Emission Control

The Liability of Positive Pressure

Traditional regenerative coke ovens typically operate under positive pressure.

This internal force pushes gases outward against the containment walls. Consequently, even minor structural imperfections can lead to the continuous leakage of pollutants into the surrounding atmosphere.

The Negative Pressure Shield

Vacuum-environment furnaces reverse this dynamic by operating under negative pressure.

This creates an internal suction effect that ensures gases are pulled inward rather than pushed outward. This pressure differential effectively locks pollutants inside the processing chamber, making significant leakage physically impossible during standard operation.

Simplifying the Industrial Process

Eliminating Chemical Recovery Risks

A major source of environmental risk in traditional coking is the complex machinery required to recover chemical by-products.

Vacuum-based systems often utilize a non-recovery design. This approach bypasses the need for complex chemical recovery stages entirely, removing a massive variable from the environmental safety equation.

Cleaner Production Cycles

By removing the chemical recovery infrastructure, the facility drastically reduces the potential for hazardous spills and leaks.

This simplification transforms the coking process from a chemical-heavy operation into a cleaner thermal process, supporting broader goals of pollution-free industrial production.

Operational Precision and Waste Reduction

Preventing Material Degradation

Beyond atmospheric emissions, vacuum environments offer significant advantages in material efficiency.

Unlike traditional furnaces, vacuum environments eliminate surface oxidation and decarburization. This ensures that the final product is cleaner and reduces the amount of material wasted due to surface defects.

Enhanced Thermal Efficiency

Vacuum furnaces provide superior capabilities for temperature measurement and control.

This accuracy ensures the process runs at optimal efficiency, reducing the energy waste and off-spec production associated with the fluctuating temperatures often found in older, traditional furnace designs.

Understanding the Trade-offs

The "Non-Recovery" Implication

It is critical to understand that the "non-recovery" design of many vacuum systems represents a strategic shift.

While this eliminates the pollution associated with recovering chemicals, it also means the facility does not harvest these by-products for other uses. This is a deliberate choice to prioritize environmental containment over chemical harvesting.

Making the Right Choice for Your Goal

When evaluating furnace technologies for your facility, consider your primary operational objectives:

- If your primary focus is strict emissions compliance: Prioritize vacuum-environment furnaces, as the negative pressure design offers the most reliable physical barrier against pollutant leakage.

- If your primary focus is operational simplicity: Choose the vacuum non-recovery design to eliminate the maintenance and environmental risks associated with chemical recovery plants.

- If your primary focus is product consistency: Leverage vacuum technology to prevent surface oxidation and ensure precise thermal regulation.

Adopting vacuum-environment technology is not just an equipment upgrade; it is a transition to a self-containing, cleaner production methodology.

Summary Table:

| Feature | Traditional Regenerative Coke Ovens | Vacuum-Environment Furnaces |

|---|---|---|

| Operating Pressure | Positive Pressure (Pushes gases out) | Negative Pressure (Pulls gases in) |

| Leakage Risk | High; gases escape via structural gaps | Minimal; pollutants are physically contained |

| Chemical Recovery | Complex recovery infrastructure required | Simplified non-recovery process possible |

| Surface Protection | Prone to oxidation and decarburization | Prevents surface oxidation and defects |

| Thermal Control | Variable/Fluctuating | High precision and uniformity |

| Environmental Impact | Risk of spills and air pollution | Cleaner production with reduced emissions |

Revolutionize Your Industrial Process with KINTEK

Are you looking to transition to a cleaner, more efficient production methodology? Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems, including Muffle, Tube, Rotary, and CVD furnaces, all customizable for your unique laboratory or industrial needs. Our vacuum technology ensures strict emissions compliance, eliminates hazardous chemical recovery risks, and prevents material degradation through precise thermal control.

Ready to upgrade to a self-containing, pollution-free furnace solution?

Contact KINTEK Experts Today to discover how our high-temp furnace systems can enhance your operational efficiency and environmental sustainability.

Visual Guide

References

- Viktoriia Ye. Khaustova, I.V. Shulga. Directions for the development of coke and non-coke metallurgy. DOI: 10.31081/1681-309x-2025-0-4-3-13

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- In what ways does the speed control of a mold withdrawal system influence the dendritic microstructure? Master PDAS.

- How is furnace brazing applied in the energy and power generation sectors? Enhance Component Reliability in Extreme Conditions

- What is the core function of a vertical vacuum furnace in purifying crude magnesium? Master Precision Vacuum Distillation

- What level of temperature uniformity can be achieved in vacuum furnaces? Achieve ±2°C Precision for Critical Applications

- What factors influence the degassing effect in vacuum annealing? Master Key Parameters for Optimal Results

- What are the main applications of vacuum furnaces? Achieve Superior Material Quality and Performance

- What are the process advantages of cyclic vacuum annealing and oxidation? Maximize Carbon Chain Yield up to 48%