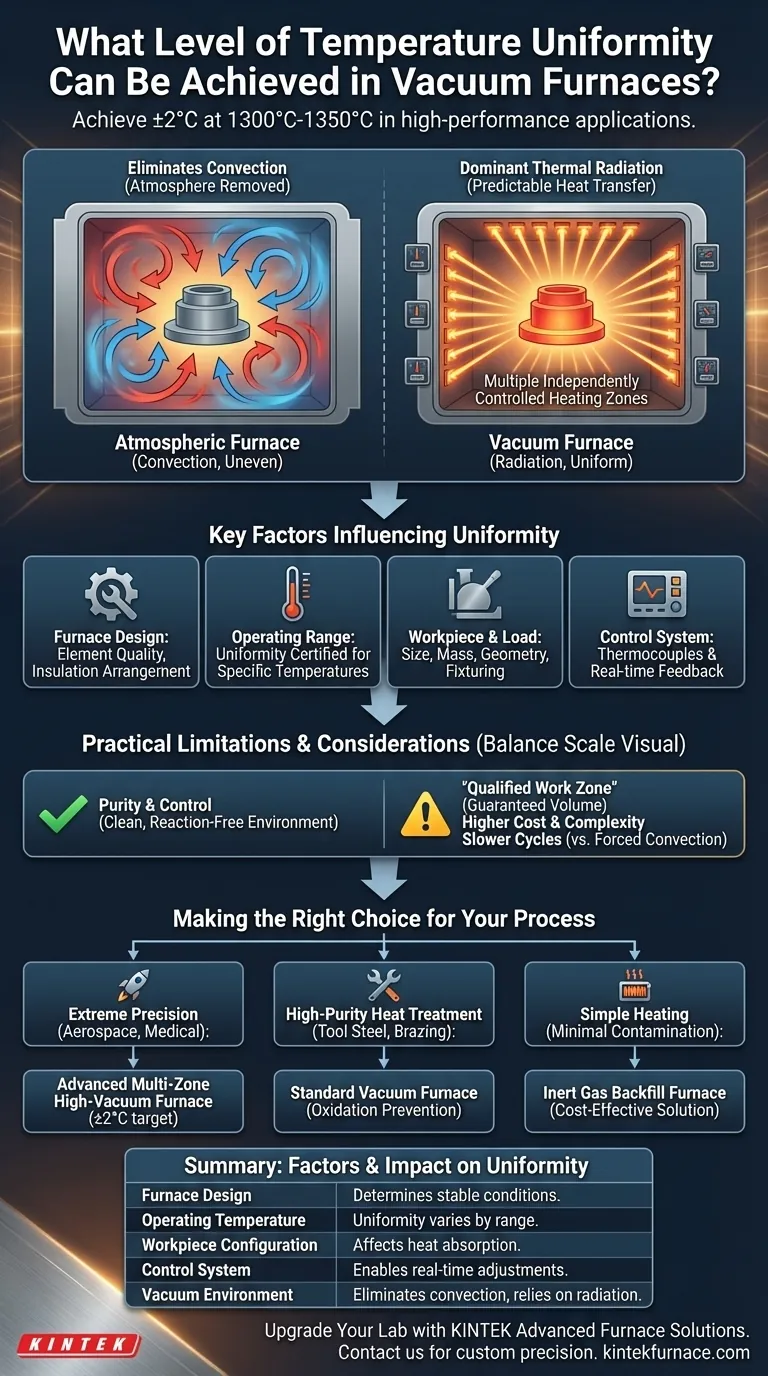

In high-performance applications, a vacuum furnace can achieve a temperature uniformity within ±2°C at operating temperatures between 1300°C and 1350°C. This level of precision is not universal, as the achievable uniformity depends heavily on the furnace's design, control systems, and the specific temperature range being targeted. Overall, vacuum furnaces are designed for exceptionally uniform and clean heating.

The core advantage of a vacuum furnace is not just tight temperature control, but the elimination of atmospheric variables. By removing air, heat transfer becomes dominated by predictable radiation, enabling a level of process purity and repeatability that conventional furnaces cannot match.

How Vacuum Enables Superior Uniformity

The defining feature of a vacuum furnace is the removal of atmosphere from the heating chamber. This fundamentally changes how heat is transferred to the workpiece, which is the key to achieving superior temperature uniformity.

The Elimination of Convection

In a traditional atmospheric furnace, air currents (convection) transfer heat in a complex and often uneven pattern, creating hot and cold spots. A vacuum removes these gas molecules, all but eliminating convection as a heat transfer mechanism. This removes a major source of temperature variability.

The Dominance of Thermal Radiation

With convection gone, heat transfer is primarily accomplished through thermal radiation. Heating elements radiate energy directly to the part being processed. This form of heat transfer is highly predictable and can be precisely controlled by the furnace's design and the placement of its heating elements.

The Power of Multiple Heated Zones

Modern vacuum furnaces do not rely on a single heat source. They are typically built with multiple, independently controlled heating zones. Sophisticated control systems use thermocouples to monitor the temperature throughout the chamber and adjust the power to each zone in real time, ensuring the entire workpiece receives a uniform amount of energy.

Key Factors That Influence Uniformity

Achieving a specific temperature tolerance is not automatic. It is the result of several interacting factors that determine the furnace's overall performance.

Furnace Design and Construction

The quality, type, and physical arrangement of the heating elements (often graphite or molybdenum) are paramount. The insulation package is also critical for preventing heat loss and maintaining stable conditions within the work zone.

Operating Temperature Range

A furnace's uniformity specification is often certified for a specific temperature range. The ability to hold a ±2°C tolerance at 1300°C may differ from its performance at 800°C, as the physics of radiation changes with temperature.

Workpiece and Load Configuration

The size, mass, density, and geometry of the parts being heated directly impact how they absorb thermal energy. The fixturing used to hold the parts can also act as a heat sink, creating cold spots if not designed correctly.

Control System and Thermocouples

The precision of the control system is what allows the furnace to execute a thermal profile accurately. The number, placement, and type of thermocouples are crucial for providing the real-time feedback needed to adjust the heated zones and guarantee uniformity across the load.

Understanding the Practical Limitations

While incredibly precise, vacuum furnaces are a specialized tool with their own set of considerations. Understanding these helps in making an informed decision.

The "Qualified Work Zone"

The tightest temperature uniformity (e.g., ±2°C) is typically only guaranteed within a specific, pre-defined volume inside the furnace known as the "qualified work zone." Placing parts outside this zone will result in less precise temperature control.

Cost and Complexity

Vacuum furnaces are more complex and carry a higher capital cost than standard atmospheric furnaces due to the need for vacuum pumps, robust chamber construction, and sophisticated control systems.

Process Purity vs. Speed

The primary benefit of a vacuum furnace is often the clean, reaction-free environment it creates, preventing oxidation and decarburization. This focus on quality and control can sometimes mean that heating cycles are slower than in furnaces that use forced convection.

Making the Right Choice for Your Process

Selecting the right thermal processing technology depends entirely on your end goal.

- If your primary focus is extreme precision for critical components (aerospace, medical implants): A multi-zone, high-vacuum furnace with advanced computer controls is necessary to achieve specifications like ±2°C.

- If your primary focus is high-purity heat treatment (tool steel, brazing): The prevention of oxidation is your main goal. A standard vacuum furnace will provide excellent uniformity and the clean environment you require.

- If your primary focus is simple heating with minimal contamination risk: A less complex solution, such as a furnace using an inert gas backfill, might be more cost-effective while still preventing oxidation.

Ultimately, a vacuum furnace provides unparalleled control over the heating environment, making precise temperature uniformity an engineered and repeatable outcome.

Summary Table:

| Factor | Impact on Temperature Uniformity |

|---|---|

| Furnace Design | Determines heating element arrangement and insulation for stable conditions |

| Operating Temperature | Uniformity varies by range, e.g., ±2°C at 1300-1350°C |

| Workpiece Configuration | Size, mass, and geometry affect heat absorption and potential cold spots |

| Control System | Multiple heated zones and thermocouples enable real-time adjustments |

| Vacuum Environment | Eliminates convection, relying on predictable thermal radiation for purity |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision-engineered products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering superior temperature uniformity and process purity for critical applications in aerospace, medical, and more. Contact us today to discuss how we can optimize your thermal processes and boost efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering