At their core, vacuum furnaces are used for sophisticated thermal processes like heat treatment, brazing, and sintering. They are essential for any application where high temperatures are required but atmospheric contamination, particularly oxidation, must be strictly avoided to achieve superior material properties.

The true value of a vacuum furnace is not just the heat it provides, but the pristine environment it creates. By removing air and other gases, it prevents unwanted chemical reactions, allowing for the creation of materials with exceptional purity, strength, and specific performance characteristics that are impossible to achieve in a conventional furnace.

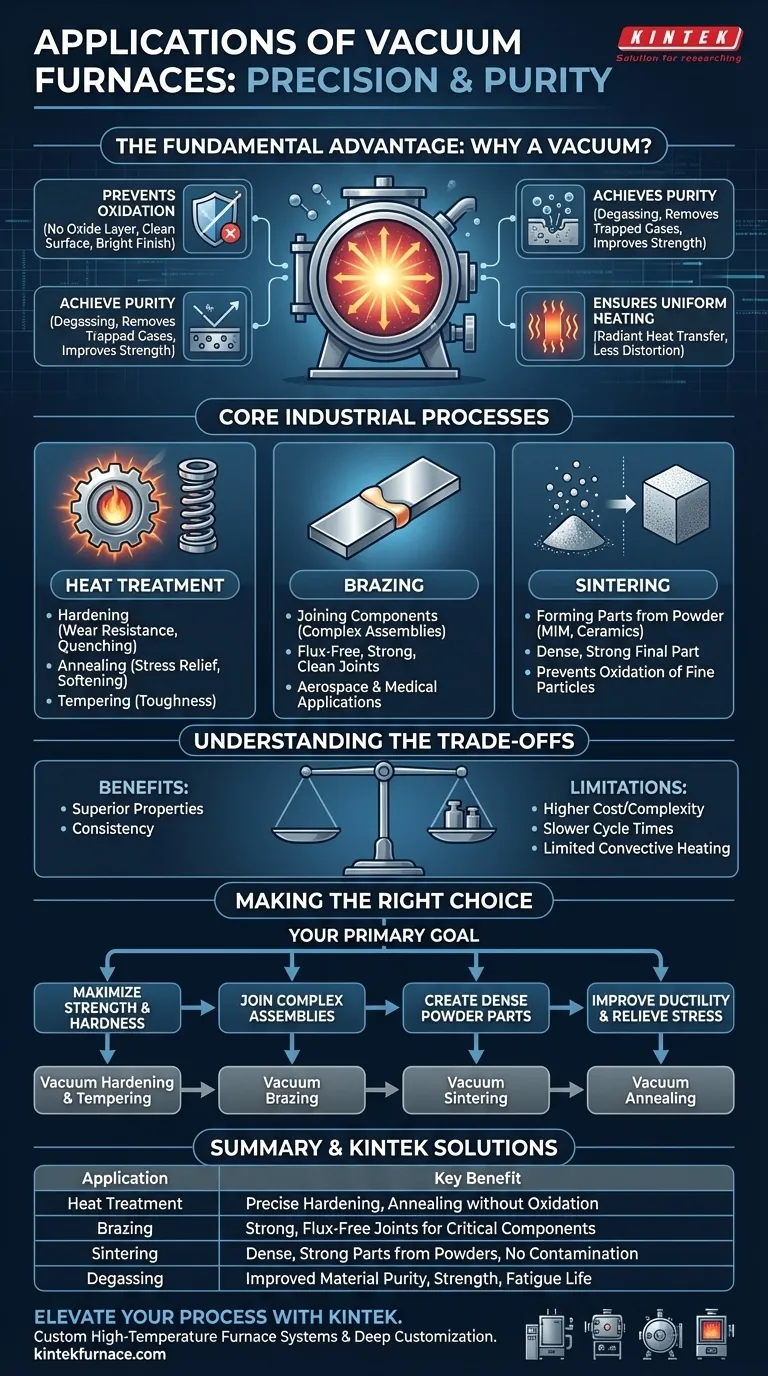

The Fundamental Advantage: Why a Vacuum?

The decision to use a vacuum furnace is driven by the need for absolute control over a material's chemistry and microstructure during heating. Removing the atmosphere solves several critical manufacturing challenges.

Preventing Oxidation and Contamination

At high temperatures, most metals react with oxygen in the air, forming a brittle, undesirable oxide layer on the surface. This is the same process as rust, but it happens almost instantly at processing temperatures.

A vacuum environment eliminates this oxygen, ensuring the material surface remains bright, clean, and free from contamination. This is non-negotiable for high-performance components.

Achieving Material Purity Through Degassing

Many materials contain trapped gases, such as hydrogen and oxygen, which can compromise their structural integrity.

Heating a material under vacuum causes these trapped gases to be pulled out of the material, a process known as degassing. This significantly improves the material's density, strength, and fatigue life.

Ensuring Uniform Heating and Cooling

In a conventional furnace, heat is transferred unevenly through convection currents in the air. A vacuum eliminates this, allowing heat to be transferred primarily through radiation.

This results in exceptionally uniform heating, reducing the risk of thermal stress, distortion, or warping in complex parts.

Core Industrial Processes Explained

The controlled environment of a vacuum furnace enables several critical manufacturing processes that are foundational to modern industry.

Heat Treatment: Hardening, Annealing, and Tempering

Heat treatment alters the physical and mechanical properties of a material. Vacuum furnaces provide unparalleled precision for these tasks.

Vacuum hardening (quenching) creates exceptional surface hardness and wear resistance in steels and alloys. Vacuum annealing softens metals, relieves internal stresses, and improves ductility without surface oxidation.

Brazing: Joining Components

Vacuum brazing is a superior method for joining components. A filler metal with a lower melting point is used to bond two parent materials together inside the vacuum.

Because there is no oxygen, the process requires no corrosive flux, resulting in an extremely strong, clean, and void-free joint. This is critical for aerospace components and medical implants.

Sintering: Forming Solid Parts from Powder

Sintering is the process of compacting and forming a solid mass of material from powder by applying heat below its melting point.

Vacuum sintering is vital for processing materials like tungsten carbide, ceramics, and parts made via Metal Injection Molding (MIM). The vacuum prevents oxidation of the fine powder particles, ensuring they bond together to form a dense, strong final part.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Higher Initial Cost and Complexity

Vacuum furnaces, with their required pumps, chambers, and control systems, represent a significantly higher capital investment than conventional atmospheric furnaces. They also require more specialized knowledge to operate and maintain.

Slower Cycle Times

Achieving a deep vacuum takes time. The "pump-down" phase before heating begins adds to the overall process cycle time, which can make vacuum processing slower than atmospheric alternatives for some applications.

Limited Convective Heating

While radiant heating is uniform, the lack of convection can be a disadvantage when very rapid heating of a large, dense load is the primary goal.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on the desired outcome for your material or component.

- If your primary focus is maximizing material strength and hardness: Vacuum hardening and tempering provide clean, predictable results without the risk of surface decarburization.

- If your primary focus is joining complex, high-purity assemblies: Vacuum brazing is the definitive choice for creating strong, flux-free joints in critical components.

- If your primary focus is creating dense, solid parts from powders: Vacuum sintering is essential to prevent oxidation and achieve the required final density and strength.

- If your primary focus is improving a material's ductility and relieving stress: Vacuum annealing offers superior surface quality and predictable softening compared to atmospheric processes.

Ultimately, choosing a vacuum furnace is a commitment to achieving the highest possible material quality and performance.

Summary Table:

| Application | Key Benefits |

|---|---|

| Heat Treatment | Precise hardening, annealing, and tempering without oxidation |

| Brazing | Strong, flux-free joints for critical components |

| Sintering | Dense, strong parts from powders with no contamination |

| Degassing | Improved material purity, strength, and fatigue life |

Ready to elevate your material processing with advanced vacuum furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior purity, strength, and performance. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance