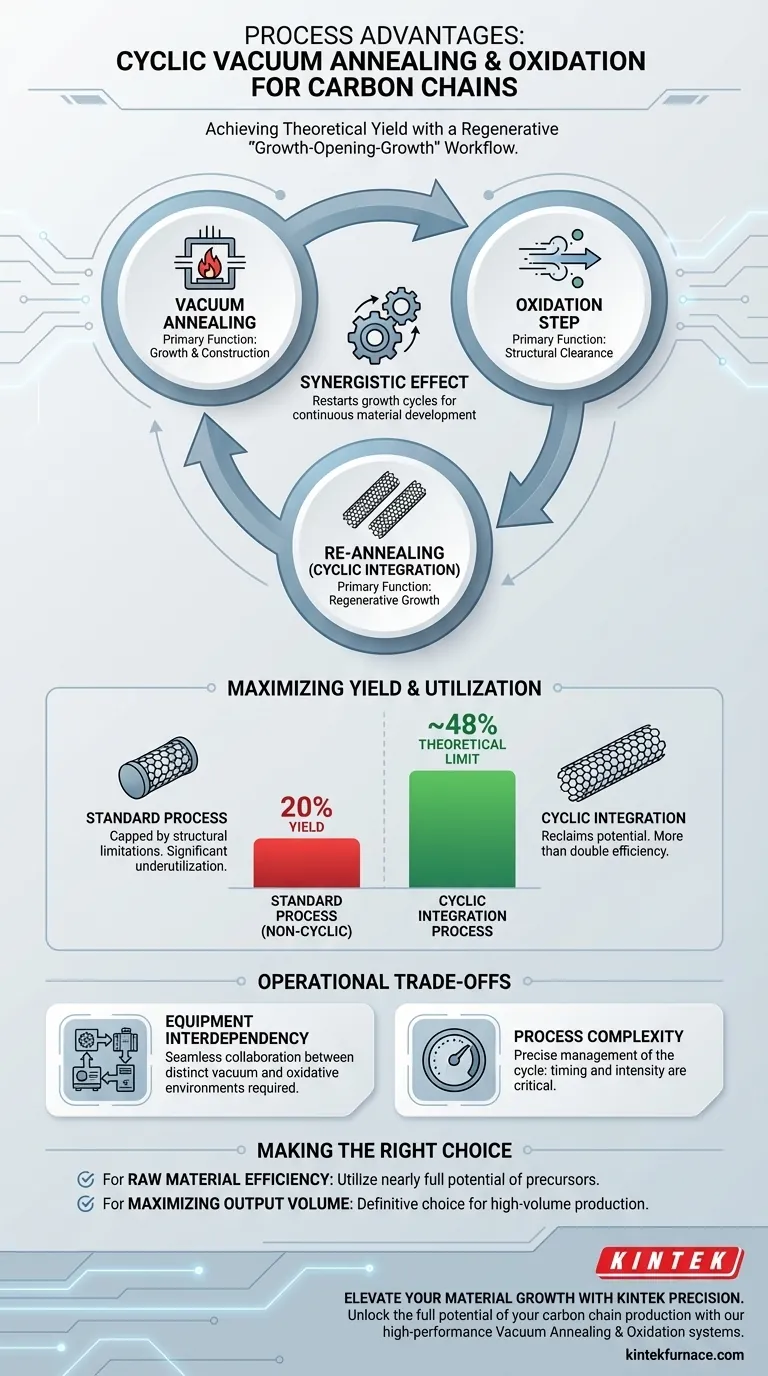

Systematic process integration is key. The primary process advantage of combining cyclic vacuum annealing with oxidation equipment lies in creating a regenerative "growth-opening-growth" workflow. While vacuum annealing drives the initial construction of carbon chains, oxidation intervenes to remove structural obstructions, allowing subsequent annealing cycles to fully utilize the potential of the raw materials.

This collaborative process resolves the limitations of single-step production, boosting the yield of carbon chains in 1.45 nm arc-discharge carbon nanotubes from roughly 20 percent to the theoretical limit of 48 percent.

The Mechanics of the Cyclic Workflow

The Role of Vacuum Annealing

The foundation of this process is the vacuum annealing equipment. Its primary function is to facilitate the initial construction of the carbon chains within the nanotubes. This step is responsible for the physical growth phase of the material.

The Role of Oxidation

Growth often stalls due to obstructions, such as closed caps on the nanotubes. The oxidation equipment resolves this by chemically removing these obstructions. By "opening caps," this step exposes the interior, providing new active sites for precursors.

The Synergistic Effect

The true process advantage emerges from the cycle: annealing for growth, oxidation for opening, and re-annealing for further growth. This repetition ensures that growth does not permanently stop at the first obstacle. Instead, the process restarts, allowing for continuous elongation and material development.

Maximizing Yield and Utilization

Breaking the 20% Barrier

In standard, non-cyclic processes, yield is often capped by structural limitations. For 1.45 nm arc-discharge carbon nanotubes, a single-step approach typically results in a yield of approximately 20 percent. This low figure represents a significant underutilization of raw materials.

Reaching the Theoretical Limit

By introducing the cyclic oxidation step, the process reclaims the potential of the raw materials. The removal of obstructions allows the re-annealing phase to drive production near the theoretical limit of 48 percent. This represents a more than double increase in efficiency compared to standard methods.

Understanding the Operational Trade-offs

Equipment Interdependency

This method relies on the seamless collaboration between two distinct types of equipment. Unlike a linear production line, this requires a workflow that can alternate between vacuum environments and oxidative atmospheres.

Process Complexity

Achieving the theoretical limit requires precise management of the "growth-opening-growth" cycle. Operators must ensure that the oxidation phase is sufficient to open caps without damaging the existing chains, and that annealing is reintroduced at the exact right moment to resume growth.

Making the Right Choice for Your Goal

When evaluating this equipment combination for your production line, consider your specific targets:

- If your primary focus is raw material efficiency: This combination is essential, as it allows you to utilize nearly the full potential of your precursors rather than discarding them after a single growth phase.

- If your primary focus is maximizing output volume: The ability to move from a 20% yield to a 48% yield makes this cyclic process the definitive choice for high-volume carbon chain production.

By leveraging the alternating forces of construction and clearance, you transform a stagnant chemical process into a dynamic, high-yield production system.

Summary Table:

| Process Phase | Primary Function | Key Advantage |

|---|---|---|

| Vacuum Annealing | Growth & Construction | Initial formation of carbon chains within nanotubes |

| Oxidation Step | Structural Clearance | Opens nanotube caps and removes growth obstructions |

| Cyclic Integration | Regenerative Growth | Restarts growth cycles to reach theoretical yield limits |

| Yield Comparison | Efficiency Optimization | Boosts raw material utilization from 20% to ~48% |

Elevate Your Material Growth with KINTEK Precision

Unlock the full potential of your carbon chain production with high-performance thermal systems from KINTEK. Our advanced Vacuum Annealing and Oxidation systems provide the precise environment needed to master the "growth-opening-growth" cycle, helping you surpass traditional yield barriers and reach theoretical limits.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temperature furnaces or fully customizable solutions tailored to your unique research needs, we deliver the reliability your project demands.

Ready to optimize your yield? Contact KINTEK today to discuss your custom furnace requirements.

Visual Guide

References

- Clara Freytag, Thomas Pichler. Systematic Optimization of the Synthesis of Confined Carbyne. DOI: 10.1002/smtd.202500075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the core function of a vacuum distillation furnace in high-hazard waste magnesium recovery processes? Purify and Recycle Valuable Metal Safely

- How does a diffusion annealing furnace enhance magnet coercivity? Boost Performance with Grain Boundary Diffusion

- Why is a vacuum drying oven preferred for ZIF-8 crystal precursors? Protect Porous Structures with Vacuum Drying

- What are the core functions of a vacuum thermal reduction furnace? Efficiently Extract Pure Magnesium

- Which types of parts are mainly suitable for heat treatment in a vertical vacuum furnace? Optimize for Minimal Distortion

- What are the main benefits of using a vacuum furnace in industrial processes? Achieve Superior Quality and Efficiency

- Why is graphite the material of choice for vacuum furnaces? Unmatched Performance in Extreme Heat

- What is the heat treatment in a vacuum oven? Achieve Superior Surface & Material Integrity