The primary benefits of a vacuum furnace are superior product quality, unparalleled process control, and greater operational efficiency. By removing the atmosphere from the heating chamber, these furnaces prevent oxidation and contamination, resulting in cleaner, stronger, and more consistent materials. This controlled environment enables precise temperature uniformity and repeatable processing cycles for applications like heat treatment, brazing, and sintering.

The fundamental advantage of a vacuum furnace is not just the heat it provides, but the environment it creates. By eliminating atmospheric variables like oxygen and impurities, you gain absolute control over the material's transformation, ensuring the final product meets exact specifications with unmatched purity and integrity.

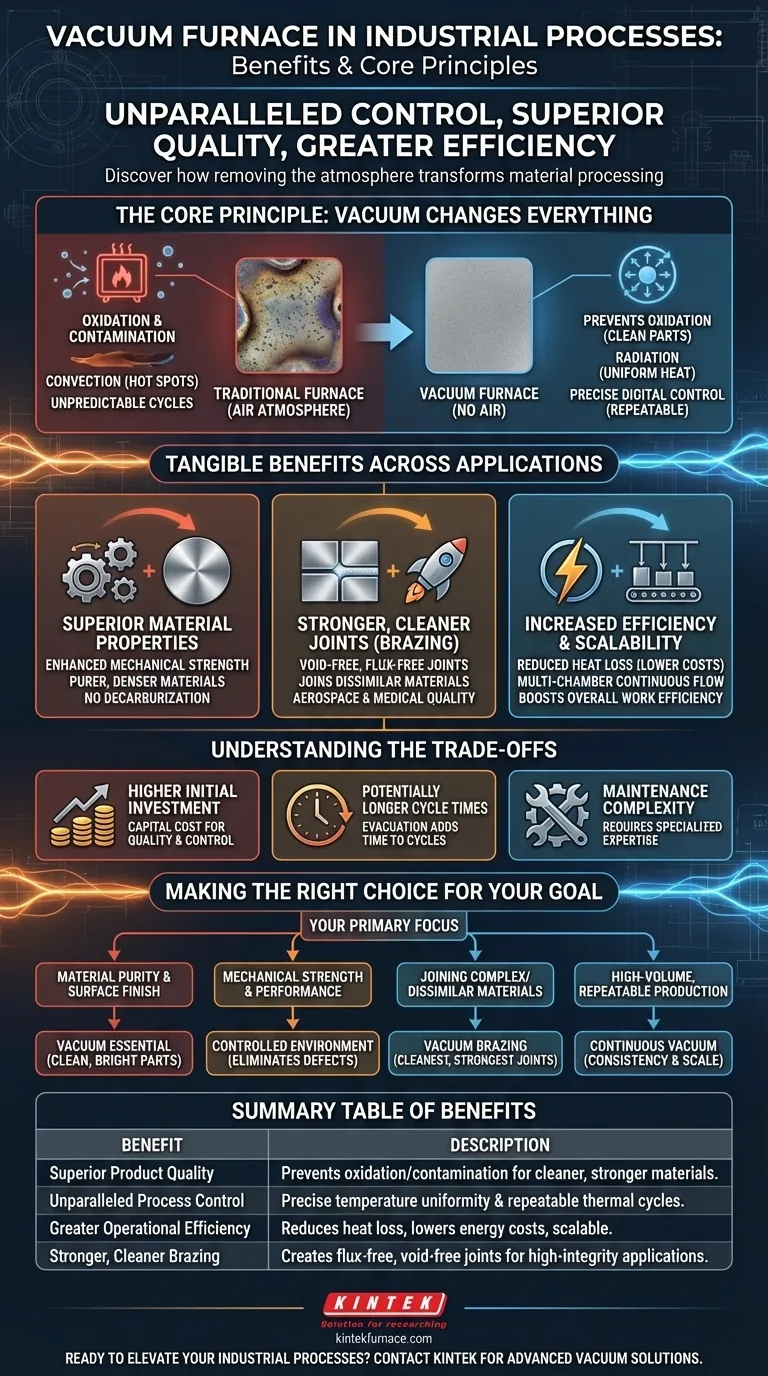

The Core Principle: Why a Vacuum Changes Everything

A traditional furnace heats a material in the presence of air. A vacuum furnace first removes that air, and this single change is the source of all its key benefits. This environment gives engineers a level of control that is impossible to achieve in an atmospheric furnace.

Eliminating Oxidation and Contamination

In a standard furnace, oxygen in the air reacts with the hot surface of a material, creating oxides—a form of scale and discoloration. A vacuum furnace removes virtually all the air, preventing oxidation before it can start.

This results in bright, clean parts straight from the furnace, eliminating the need for post-process cleaning. Furthermore, the vacuum actively pulls out impurity gases from the material itself, leading to a purer and denser final product, which is critical for sintering advanced ceramics and carbides.

Achieving Absolute Temperature Uniformity

In an air-filled furnace, heat transfer is dominated by convection, which can create hot spots and uneven heating. In a vacuum, convection is eliminated. Heat is transferred primarily through radiation.

This means every surface of the part, regardless of its position, receives the same amount of heat energy. This exceptional temperature uniformity minimizes thermal stress, prevents part distortion, and ensures the entire component receives the intended treatment perfectly.

Enabling Precise Process Control

Modern vacuum furnaces are managed by sophisticated computer systems. When combined with the stable, inert environment of a vacuum, these controls allow for incredibly precise and repeatable thermal cycles.

Engineers can program exact heating rates, soak times, and rapid cooling (quenching) profiles. This ensures that every part in a batch, and every subsequent batch, is processed with identical parameters, guaranteeing consistent quality and predictable material properties at scale.

Tangible Benefits Across Industrial Applications

The precise control offered by a vacuum environment translates directly into measurable improvements in quality and performance across various industrial processes.

Superior Material Properties

For metals undergoing heat treatment, the absence of oxygen prevents surface decarburization, a process that can weaken the material. This results in components with enhanced mechanical properties, including improved strength, hardness, and corrosion resistance.

Stronger, Cleaner Joints in Brazing

Vacuum brazing is a premier process for joining components. It creates exceptionally strong, void-free joints without the need for corrosive fluxes.

Because the process is so clean, it is ideal for joining dissimilar or "unweldable" materials and is the standard for critical applications in aerospace, medical devices, and even high-end jewelry manufacturing where a flawless finish is paramount.

Increased Efficiency and Scalability

While a vacuum furnace is a sophisticated piece of equipment, it is highly energy-efficient. The vacuum acts as a powerful insulator, dramatically reducing heat loss to the outside and lowering operational costs.

For high-volume needs, multi-chamber continuous vacuum furnaces allow for a streamlined workflow, integrating the benefits of vacuum processing into a mass production environment and boosting overall work efficiency.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the solution for every heating application. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

The complexity of the vacuum pumps, chamber, and control systems means that vacuum furnaces represent a significantly higher capital investment compared to standard atmospheric furnaces. The cost is a trade-off for the superior quality and control achieved.

Potentially Longer Cycle Times

The process of evacuating the chamber to create the vacuum adds time to the beginning of every cycle. While heating and cooling can be very rapid, the overall batch processing time may be longer than in a simpler atmospheric furnace where parts can be loaded directly into a hot chamber.

Maintenance Complexity

A vacuum furnace is a more complex system. The vacuum pumps, seals, and advanced sensor arrays require specialized maintenance and technical expertise to keep them operating at peak performance.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on the desired outcome for your material and your operational priorities.

- If your primary focus is material purity and surface finish: A vacuum furnace is essential for preventing oxidation and producing clean, bright parts right out of the furnace.

- If your primary focus is mechanical strength and performance: The controlled environment eliminates surface defects and internal impurities, leading to superior material properties in heat-treated or sintered components.

- If your primary focus is joining complex or dissimilar materials: Vacuum brazing provides the cleanest, strongest, and most repeatable method for creating high-integrity joints without flux.

- If your primary focus is high-volume, repeatable production: A continuous vacuum furnace provides the consistency and scale needed for mass production of high-quality parts that must meet strict specifications.

Ultimately, investing in a vacuum furnace is an investment in absolute control over your material's final properties and quality.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Product Quality | Prevents oxidation and contamination for cleaner, stronger materials with enhanced mechanical properties. |

| Unparalleled Process Control | Enables precise temperature uniformity and repeatable thermal cycles via advanced computer systems. |

| Greater Operational Efficiency | Reduces heat loss, lowers energy costs, and supports scalable production with multi-chamber designs. |

| Stronger, Cleaner Joints in Brazing | Creates flux-free, void-free joints ideal for dissimilar materials in aerospace and medical devices. |

Ready to elevate your industrial processes with advanced vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on material purity, mechanical strength, or high-volume production, we can help you achieve superior results. Contact us today to discuss how our expertise can benefit your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a high-temperature vacuum furnace facilitate the synthesis of graphene? Master Precise Catalyst Mediation

- Why is dual monitoring used for Tantalum annealing? Achieve 20K Precision in Vacuum Furnaces

- What is the function of introducing 150 Pa of argon gas into a furnace during the vacuum refining of AM60 magnesium alloy?

- What is the necessity of using a vacuum drying oven for Ni/NiO@GF precursors? Unlock Structural Precision

- What key experimental environments do vacuum resistance furnaces provide for Ti–50Zr alloys? Ensure Material Purity

- How does a vacuum furnace create its working environment? Uncover the Secrets to Purity and Precision

- How are vacuum furnaces classified based on chamber design? Explore Horizontal, Vertical, and Bottom-Loading Types

- How does a high-precision vacuum drying oven contribute to the preparation of LiFePO4 electrode slurries?