A vacuum drying oven is preferred over a standard oven because it utilizes negative pressure to significantly lower the boiling point of solvents like methanol and ethanol. This enables the complete removal of liquids from the complex ZIF-8 pore structure at a gentle temperature (typically 60°C), thereby preventing the thermal damage, structural collapse, and oxidation that occur in standard high-temperature convection drying.

The Core Takeaway

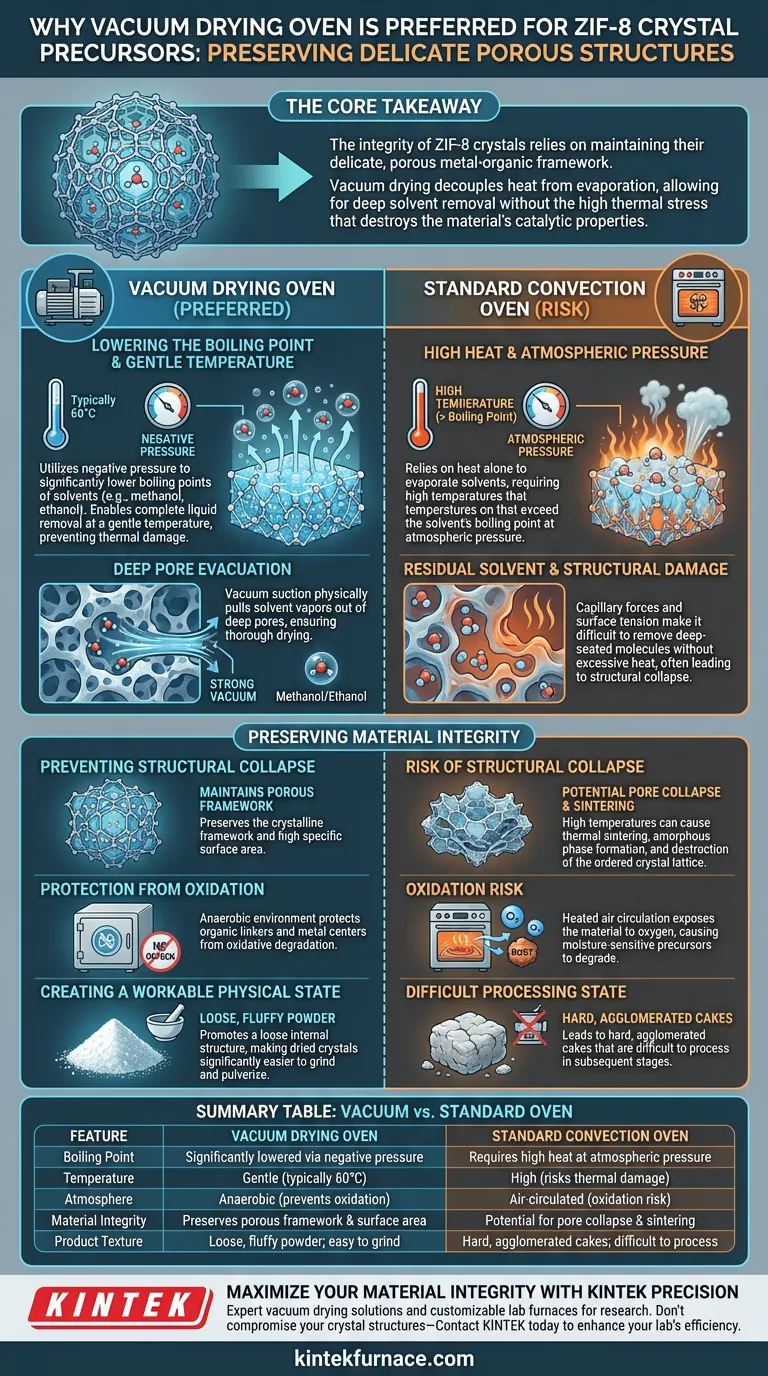

The integrity of ZIF-8 crystals relies on maintaining their delicate, porous metal-organic framework. Vacuum drying decouples heat from evaporation, allowing for deep solvent removal without the high thermal stress that destroys the material's catalytic properties.

The Mechanism of Solvent Removal

Lowering the Boiling Point

Standard ovens rely on heat alone to evaporate solvents, requiring temperatures that exceed the solvent's boiling point at atmospheric pressure. Vacuum drying operates under negative pressure, which fundamentally alters the thermodynamics of the process.

By reducing the pressure, the boiling point of solvents (such as methanol, ethanol, or water) drops significantly. This allows the liquid to turn into vapor at much lower temperatures, often around 60°C for ZIF-8 protocols.

Deep Pore Evacuation

ZIF-8 crystals possess a highly porous internal structure where solvent molecules can become trapped. In a standard oven, capillary forces and surface tension can make it difficult to remove these deep-seated molecules without excessive heat.

The vacuum suction effect physically pulls solvent vapors out of these deep pores. This ensures thorough drying and prevents residual solvent from interfering with subsequent chemical reactions or applications.

Preserving Material Integrity

Preventing Structural Collapse

The primary risk during the drying of Metal-Organic Frameworks (MOFs) like ZIF-8 is the collapse of the pore structure. High temperatures utilized in standard ovens can cause thermal sintering or undesired phase changes.

By drying at a lower temperature, the vacuum method preserves the crystalline framework. This maintains the high specific surface area required for the material to function effectively as a catalyst or precursor.

Protection from Oxidation

Standard ovens circulate heated air, exposing the material to oxygen. Many precursors, including ZIF-8 components, are moisture-sensitive or prone to oxidative degradation when heated in air.

A vacuum oven eliminates oxygen from the environment. This anaerobic condition protects organic linkers and metal centers from deteriorating, ensuring the chemical purity of the final precursor.

Creating a Workable Physical State

Beyond chemical stability, the drying method affects the physical handling of the material. Vacuum drying tends to promote a loose internal structure within the precursor.

This "fluffy" or loose state makes the dried crystals significantly easier to grind and pulverize. In contrast, standard drying can lead to hard, agglomerated cakes that are difficult to process in subsequent sintering or shaping stages.

Understanding the Trade-offs

The Risk of Standard Convection

It is critical to understand why a standard oven is a liability for this specific material. If you attempt to dry ZIF-8 at atmospheric pressure, you are forced to raise the temperature to evaporate the solvent.

This increased heat often leads to the formation of amorphous phases, effectively destroying the ordered crystal lattice you worked to synthesize. Furthermore, without the "pull" of the vacuum, residual moisture often remains trapped, causing structural collapse when the material is later subjected to high-temperature carbonization.

Making the Right Choice for Your Goal

When setting up your synthesis protocol, consider your specific priorities:

- If your primary focus is Structural Fidelity: Use vacuum drying to maintain the maximum possible specific surface area and prevent pore collapse.

- If your primary focus is Chemical Purity: Rely on the vacuum environment to prevent oxidation and ensure no residual solvent remains to contaminate downstream reactions.

- If your primary focus is Process Efficiency: Utilize the vacuum to reduce the energy required for evaporation and to produce a loose powder that reduces grinding time.

By utilizing vacuum drying, you ensure the ZIF-8 precursor retains the critical porous architecture and chemical stability required for high-performance applications.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Convection Oven |

|---|---|---|

| Boiling Point | Significantly lowered via negative pressure | Requires high heat at atmospheric pressure |

| Temperature | Gentle (typically 60°C) | High (risks thermal damage) |

| Atmosphere | Anaerobic (prevents oxidation) | Air-circulated (oxidation risk) |

| Material Integrity | Preserves porous framework and surface area | Potential for pore collapse and sintering |

| Product Texture | Loose, fluffy powder; easy to grind | Hard, agglomerated cakes; difficult to process |

Maximize Your Material Integrity with KINTEK Precision

Preserving the delicate architecture of Metal-Organic Frameworks like ZIF-8 requires more than just heat—it requires precise control over pressure and environment. KINTEK provides industry-leading vacuum drying solutions alongside our expert R&D-backed manufacturing of Muffle, Tube, Rotary, and CVD systems.

Whether you are drying precursors or conducting high-temperature synthesis, our customizable lab furnaces are designed to meet the unique needs of your research. Don't compromise your crystal structures—Contact KINTEK today to discover how our specialized equipment can enhance your lab's efficiency and results.

Visual Guide

References

- Jianping Chen, Wei‐Ning Wang. Highly efficient CO<sub>2</sub> electrochemical reduction on dual metal (Co–Ni)–nitrogen sites. DOI: 10.1039/d3ta05654f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role do laboratory arc furnaces and tungsten electrodes play in TiCo1-xCrxSb synthesis? Expert Material Analysis

- What are the primary benefits of vacuum tempering? Achieve Superior Surface Quality and Enhanced Material Properties

- How do costs compare between low vacuum and high vacuum furnaces? Find the Best Fit for Your Budget and Needs

- What is the function of a laboratory vacuum drying oven in carbon nitride catalyst processing? Ensure Optimal Performance

- What materials are used in a vacuum furnace? Key Components for Extreme Heat & Purity

- Which metals are prone to oxidation during melting? Protect with vacuum or inert gas furnaces

- Why is a high-temperature vacuum furnace with argon protection required for sintering NiTi/HA? Ensure Phase Purity

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision