At its core, a vacuum furnace is a system of specialized components, each built from materials carefully selected to withstand extreme heat in an oxygen-free environment. The primary materials include high-strength steel for the furnace body, refractory metals like molybdenum and tungsten or graphite for the heating elements, and advanced insulators like carbon felt or ceramic fiber to contain the intense thermal energy.

The selection of materials for a vacuum furnace is not arbitrary; it is a direct function of the intended thermal process. The core challenge is balancing extreme temperature resistance, chemical inertness under vacuum, and structural integrity, with the choice between a graphite or all-metal "hot zone" being the most critical decision.

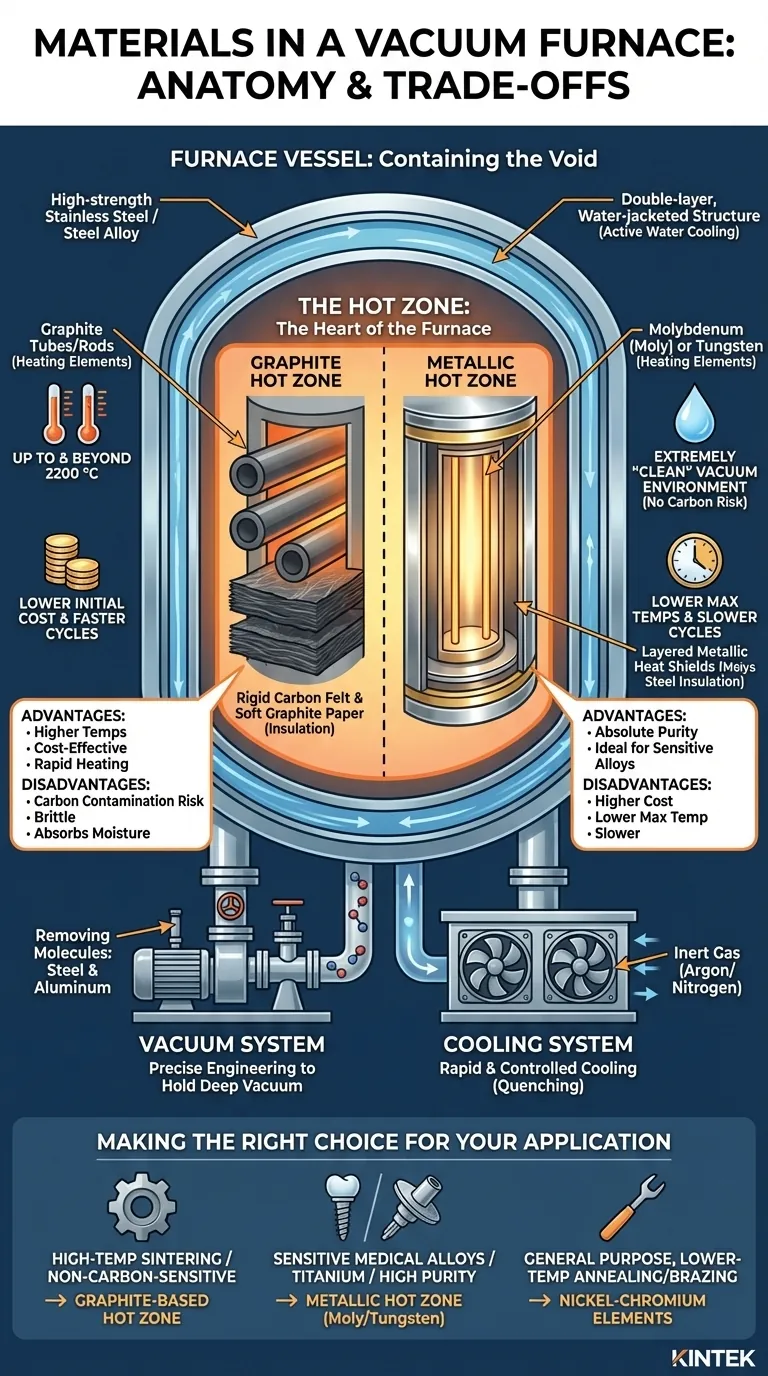

The Anatomy of a Vacuum Furnace: A Material-Driven Design

A vacuum furnace is more than a single vessel; it's an integrated system where each component's material is chosen to perform a specific function under demanding conditions.

The Furnace Vessel: Containing the Void

The outer shell, or vessel, provides the structural foundation and maintains the vacuum seal. Its primary job is to withstand atmospheric pressure from the outside when a vacuum is pulled inside.

Materials like high-strength stainless steel or other steel alloys are the standard. They provide the necessary strength and are relatively easy to fabricate into the required cylindrical or rectangular shape. To manage heat transfer, the vessel is almost always a double-layer, water-jacketed structure that actively circulates water to keep the shell cool.

The Hot Zone: The Heart of the Furnace

The "hot zone" is the internal chamber where the heating takes place. The materials used here define the furnace's capabilities and limitations. There are two primary design philosophies: graphite-based and all-metal.

Graphite and Carbon Composite Hot Zones

Graphite is a popular choice for its ability to handle extremely high temperatures (up to and beyond 2200 °C) and its excellent thermal stability.

The heating elements are often graphite tubes or rods, while the insulation consists of rigid carbon felt and soft graphite paper. This combination is lightweight, has low thermal mass for rapid heating and cooling, and is cost-effective.

Metallic Hot Zones

For processes where carbon contamination is a critical concern (such as with certain titanium or medical-grade alloys), an all-metal hot zone is necessary.

The heating elements are made from refractory metals, most commonly molybdenum (Moly) or tungsten. Insulation is not a fiber or felt, but rather a series of layered metallic heat shields, also made from molybdenum and stainless steel, which reflect thermal energy back into the zone.

Supporting Systems: Enabling the Process

The vessel and hot zone are supported by several other systems, each with its own material requirements.

The Vacuum System

This system, comprising pumps and valves, is built from durable metals like steel and aluminum. The critical factor here is not exotic materials, but precise engineering to create and hold a deep vacuum, removing reactive molecules like oxygen.

The Cooling System

Rapid and controlled cooling (quenching) is a key part of many heat-treatment processes. This is accomplished by backfilling the chamber with an inert gas, typically Argon or Nitrogen, which is circulated by a high-power fan. The water circulating in the vessel's jacket helps remove this heat from the system.

Understanding the Trade-offs: Graphite vs. Metallic

The decision between a graphite and an all-metal hot zone is the most significant choice in vacuum furnace design, presenting a clear set of trade-offs.

Graphite Hot Zones

- Advantages: Capable of higher temperatures, significantly lower initial cost, and faster heating/cooling cycles due to lower thermal mass.

- Disadvantages: Graphite can be a source of carbon contamination, which is unacceptable for certain alloys. It is also more brittle and can absorb moisture from the air, requiring a "burn-out" cycle to evacuate it.

Metallic Hot Zones

- Advantages: Provides an extremely "clean" vacuum environment with no risk of carbon contamination. This is essential for processing reactive or high-purity metals.

- Disadvantages: Higher initial cost, lower maximum operating temperatures compared to graphite (tungsten is better than molybdenum, but both are below peak graphite performance), and slower thermal cycles due to the higher mass of the metallic shields.

Making the Right Choice for Your Application

The ideal furnace material composition depends entirely on the process being performed and the parts being treated.

- If your primary focus is high-temperature sintering or processing non-carbon-sensitive materials: A graphite-based hot zone is the most cost-effective and thermally efficient choice.

- If your primary focus is processing highly sensitive medical alloys, titanium, or materials where carbon contamination is unacceptable: A metallic hot zone using molybdenum or tungsten is required for its absolute purity.

- If your primary focus is general-purpose, lower-temperature annealing or brazing: Furnaces with heating elements made from alloys like nickel-chromium offer a durable and economical solution.

By understanding how each material contributes to the vacuum environment, you can ensure the integrity and success of your thermal process.

Summary Table:

| Component | Key Materials | Primary Function |

|---|---|---|

| Furnace Vessel | High-strength stainless steel | Structural integrity & vacuum seal |

| Heating Elements | Graphite, Molybdenum, Tungsten | Generate extreme heat in a vacuum |

| Insulation/Hot Zone | Carbon felt, Graphite paper, Metallic heat shields | Contain thermal energy |

| Critical Choice | Graphite Hot Zone vs. All-Metal Hot Zone | Balances cost, temperature, and contamination risk |

Struggling to select the right furnace materials for your specific process?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide you with the perfect high-temperature furnace solution. Whether your priority is the extreme temperature capability and cost-efficiency of a graphite hot zone or the absolute purity of an all-metal system for sensitive alloys, our experts will guide you.

Our diverse product line, including Vacuum & Atmosphere Furnaces, is backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact our experts today to discuss your application and ensure your thermal process is a complete success.

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What factors influence the design and selection of heating elements in vacuum furnaces? Optimize for Temperature, Purity, and Cost

- How does vacuum brazing work? Achieve Superior Joint Integrity for Critical Applications

- What role does a vacuum sintering furnace play in fine ceramic component production? Achieve High-Purity, Dense Ceramics

- How does vacuum hardening work? Achieve Superior Hardness with a Clean, Bright Finish

- Why is a precise and slow cooling rate necessary during Nb3Sn heat treatment? Ensure Peak Superconducting Performance

- Why is a vacuum oven utilized for drying NaFePO4 gel? Prevent Oxidation and Ensure Chemical Homogeneity

- What are the advantages of using a vacuum drying oven for ceramic powders? Preserve Purity and Sinterability

- How does a crucible furnace operate? Master Indirect Heating for Pure Metal Melting