Vacuum tempering provides a powerful combination of superior surface quality, enhanced material properties, and operational efficiency. This advanced heat treatment method leverages a vacuum environment to prevent the negative surface reactions, such as oxidation and discoloration, that occur in traditional atmosphere furnaces. The result is a cleaner, stronger, and more consistent final product achieved through a faster and more environmentally friendly process.

The core benefit of vacuum tempering is the elimination of atmospheric gases during the heating cycle. By removing reactive elements like oxygen, the process protects the steel's surface integrity, ensuring that the material's inherent metallurgical properties are preserved and enhanced without contamination or degradation.

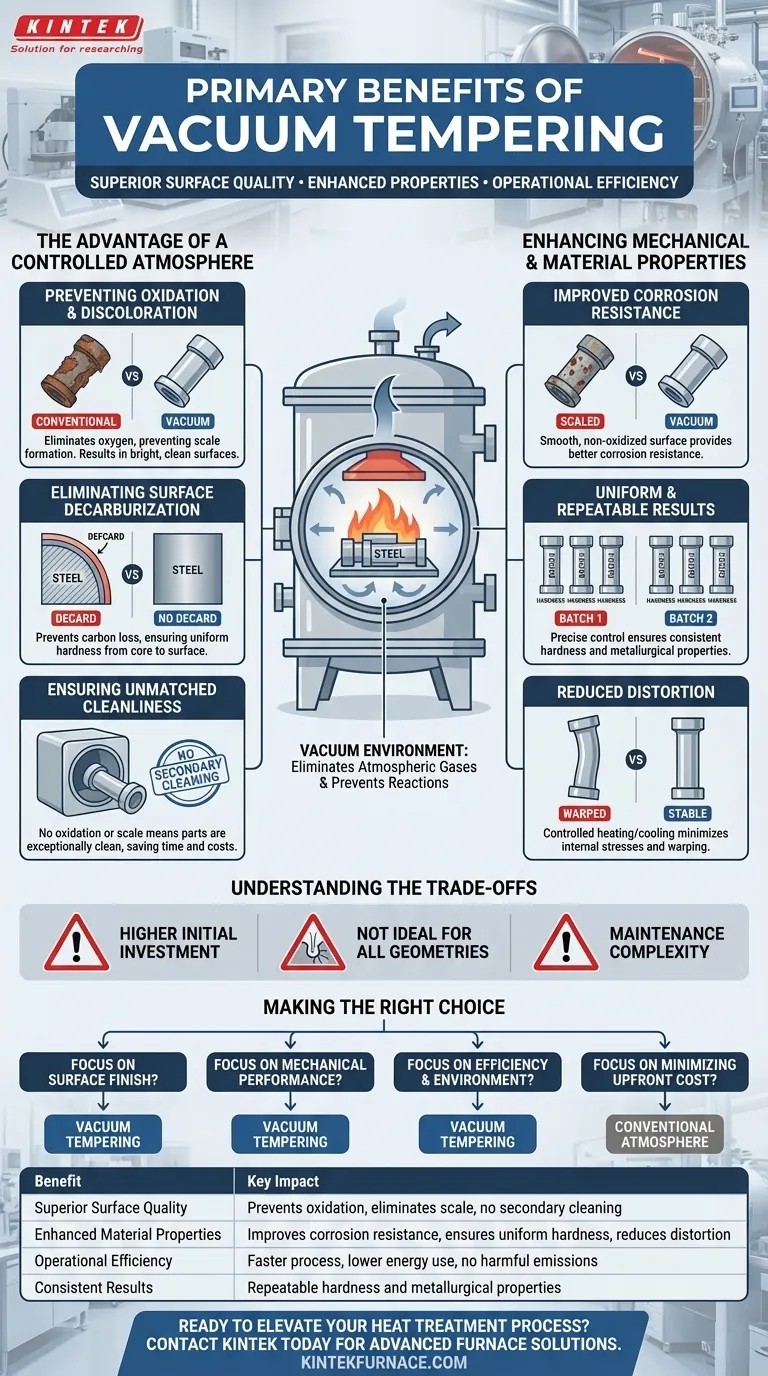

The Advantage of a Controlled Atmosphere

The primary function of the vacuum is to create a chemically neutral environment. This prevents unwanted reactions that are common at the high temperatures required for tempering.

Preventing Oxidation and Discoloration

In a conventional furnace, the oxygen in the air reacts with the hot steel surface, forming a dark, flaky layer of oxide known as scale. Vacuum tempering removes virtually all the oxygen, preventing this reaction entirely. Parts emerge from the furnace with a bright, clean, and scale-free surface.

Eliminating Surface Decarburization

Decarburization is the loss of carbon from the surface of the steel, which can occur at high temperatures. This process softens the surface layer, compromising the component's wear resistance and fatigue life. The inert vacuum environment prevents this loss, ensuring uniform hardness from the core to the absolute surface of the part.

Ensuring Unmatched Cleanliness

Because oxidation is prevented, components treated in a vacuum are exceptionally clean and dry. This often eliminates the need for secondary cleaning operations like shot blasting or chemical pickling, saving both time and money in the production workflow.

Enhancing Mechanical and Material Properties

By protecting the part's surface, the vacuum process directly contributes to superior and more reliable mechanical properties.

Improved Corrosion Resistance

An oxidized or scaled surface contains microscopic imperfections that can trap moisture and act as initiation sites for rust. The smooth, clean, and non-oxidized surface produced by vacuum tempering provides a more passive and inherently corrosion-resistant finish.

Uniform and Repeatable Results

Vacuum furnaces provide precise temperature control and uniform heating, often using convection assisted by a backfill of inert gas. This, combined with the prevention of surface defects, leads to extremely consistent and reproducible hardness and metallurgical properties from batch to batch, which is critical for high-performance applications.

Reduced Distortion

Modern vacuum furnaces allow for highly controlled heating and cooling rates. This ability to manage thermal gradients reduces the internal stresses that cause parts to warp or distort during heat treatment, improving dimensional stability for complex or delicate geometries.

Understanding the Trade-offs and Considerations

While powerful, vacuum tempering is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces are technologically complex and represent a significantly higher capital investment compared to standard atmosphere furnaces. This cost must be weighed against the long-term benefits of higher quality and reduced secondary processing.

Not Ideal for All Geometries

Tightly packed loads or components with deep, blind holes can be challenging to process. These features can trap small amounts of atmosphere, creating "virtual leaks" that may compromise the surface finish in those specific areas. Careful racking and loading are essential.

Maintenance Complexity

The systems required to create and maintain a vacuum—including pumps, seals, and advanced controls—demand specialized and diligent maintenance compared to simpler furnace designs.

Making the Right Choice for Your Goal

To decide if vacuum tempering is the appropriate process, consider your most critical outcome.

- If your primary focus is surface finish and aesthetics: Vacuum tempering is the definitive choice, as it eliminates the need for post-process cleaning or blasting to remove scale.

- If your primary focus is maximizing mechanical performance and consistency: The process offers unparalleled control for critical components, preventing surface defects and ensuring highly repeatable metallurgical results.

- If your primary focus is operational efficiency and environmental impact: Vacuum tempering provides a cleaner, safer, and often faster process with lower energy consumption and no harmful emissions.

- If your primary focus is minimizing upfront cost: Conventional atmosphere tempering may be more economical initially, but you must factor in the potential costs of secondary operations and a higher part rejection rate.

By understanding the principles of a vacuum environment, you can select the heat treatment process that delivers the precise quality and performance your components demand.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Superior Surface Quality | Prevents oxidation and discoloration, eliminating scale and the need for secondary cleaning |

| Enhanced Material Properties | Improves corrosion resistance, ensures uniform hardness, and reduces distortion |

| Operational Efficiency | Faster process, lower energy use, and no harmful emissions, saving time and costs |

| Consistent Results | Provides repeatable hardness and metallurgical properties with precise temperature control |

Ready to elevate your heat treatment process? Contact KINTEK today to discover how our advanced high-temperature furnace solutions—including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems—can be customized to meet your unique needs. With exceptional R&D and in-house manufacturing, we deliver reliable, efficient, and precise equipment to enhance your lab's performance. Get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion