From a purely financial perspective, a low vacuum furnace has a lower initial purchase price and lower ongoing operational costs. A high vacuum furnace represents a significantly larger investment in both upfront equipment and long-term maintenance due to its more complex systems needed to achieve a cleaner processing environment.

The choice between a low and high vacuum furnace is not just about initial cost. It's a fundamental decision about balancing production speed and budget against the required level of atmospheric purity for your specific material and process.

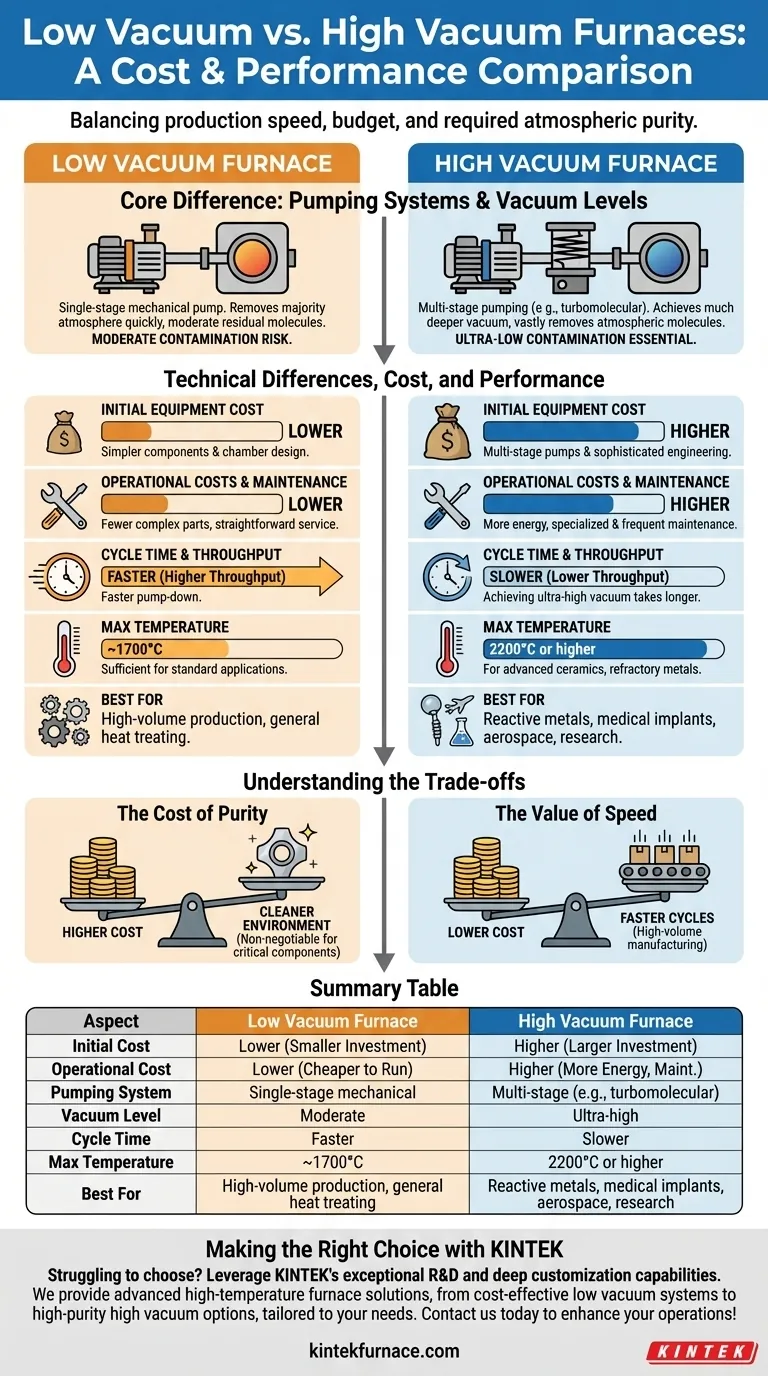

The Core Difference: Pumping Systems and Vacuum Levels

The cost and capability of any vacuum furnace are dictated by its pumping system and the quality of the vacuum it can create.

Low Vacuum: The Workhorse Approach

Low vacuum furnaces typically use a single-stage mechanical pump, such as a rotary vane pump. This system is robust and relatively simple.

It removes the majority of the atmosphere quickly but leaves behind more residual molecules. This results in a moderate, yet acceptable for many applications, risk of contamination.

High Vacuum: The High-Purity System

High vacuum furnaces employ a multi-stage pumping system. A mechanical "roughing" pump first removes the bulk of the air, then a secondary pump (like a turbomolecular or diffusion pump) takes over to achieve a much deeper vacuum.

This complex setup removes vastly more atmospheric molecules, creating an extremely low-contamination environment essential for sensitive processes.

How Technical Differences Drive Cost and Performance

The pumping system is the primary driver of cost, but it also directly impacts every aspect of the furnace's performance.

Initial Equipment Cost

A low vacuum furnace is less expensive because its components—primarily a single mechanical pump and simpler chamber design—are less costly to manufacture.

The multi-stage pumps, sophisticated controls, and more robust chamber engineering required for a high vacuum furnace substantially increase its initial purchase price.

Operational Costs and Maintenance

With fewer complex parts, a low vacuum furnace is generally cheaper to run and maintain. The mechanical pumps are workhorses that require straightforward service.

High vacuum systems consume more energy and their sophisticated pumps require specialized, more frequent, and more expensive maintenance to ensure performance and reliability.

Cycle Time and Throughput

Low vacuum furnaces have faster pump-down times. This translates directly to shorter overall cycle times, enabling higher production throughput.

High vacuum furnaces are inherently slower. Achieving the ultra-high vacuum level required for high-purity processing takes significantly more time, extending the overall cycle.

Temperature and Material Capability

Low vacuum furnaces are often limited to a maximum temperature of around 1700°C. This is sufficient for a wide range of standard heat-treating and brazing applications.

High vacuum furnaces can reach 2200°C or higher. This capability, combined with the ultra-pure atmosphere, is necessary for processing advanced ceramics, refractory metals, and other high-performance materials.

Understanding the Trade-offs

Choosing the wrong furnace type based on cost alone can lead to process failure or unnecessary expense.

The Cost of Purity

The higher cost of a high vacuum furnace is a direct payment for a cleaner environment. For reactive metals (like titanium) or critical components (like medical implants), preventing oxidation and contamination is non-negotiable.

The Value of Speed

The lower cost and faster cycle times of a low vacuum furnace make it the clear winner for high-volume manufacturing where extreme purity is not the primary driver. Its efficiency translates to a lower cost-per-part.

The Risk of Mismatch

Using a low vacuum furnace for a process that demands high purity will likely result in failed parts, material degradation, and wasted resources, negating any initial cost savings.

Conversely, using a high vacuum furnace for a simple process that doesn't require its capabilities is an inefficient use of capital—a case of expensive over-engineering.

Making the Right Choice for Your Application

Your final decision must be guided by your specific process requirements, not just the initial price tag.

- If your primary focus is high-volume production or general heat treating: The speed and lower operating cost of a low vacuum furnace offer the best economic value.

- If your primary focus is processing reactive metals, medical implants, or aerospace components: The process integrity provided by a high vacuum furnace is a necessary investment to ensure quality and prevent failure.

- If your primary focus is research or processing advanced materials at extreme temperatures: A high vacuum furnace is essential for its temperature range and the ultra-pure environment it creates.

Ultimately, the right furnace is the one that reliably meets the technical demands of your application within a sustainable budget.

Summary Table:

| Aspect | Low Vacuum Furnace | High Vacuum Furnace |

|---|---|---|

| Initial Cost | Lower | Higher |

| Operational Cost | Lower | Higher |

| Pumping System | Single-stage mechanical | Multi-stage (e.g., turbomolecular) |

| Vacuum Level | Moderate | Ultra-high |

| Cycle Time | Faster | Slower |

| Max Temperature | ~1700°C | 2200°C or higher |

| Best For | High-volume production, general heat treating | Reactive metals, medical implants, aerospace, research |

Struggling to choose the right vacuum furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need cost-effective low vacuum systems or high-purity high vacuum options, we ensure optimal performance and efficiency. Don't let budget or process demands hold you back—contact us today to discuss how our furnaces can enhance your operations and deliver reliable results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties