In a vacuum furnace, contamination refers to the presence of any unwanted substance that degrades the required vacuum level, reacts negatively with the parts being processed, or damages the furnace components themselves. This includes not only obvious dirt and air leaks but also invisible gases and elements released from the workpiece and even the furnace's internal materials when heated.

The core challenge of vacuum furnace operation is not just removing air, but managing the invisible sources of contamination. True process control comes from understanding that contaminants are often released from within the chamber—from the parts you're heating and the furnace materials themselves.

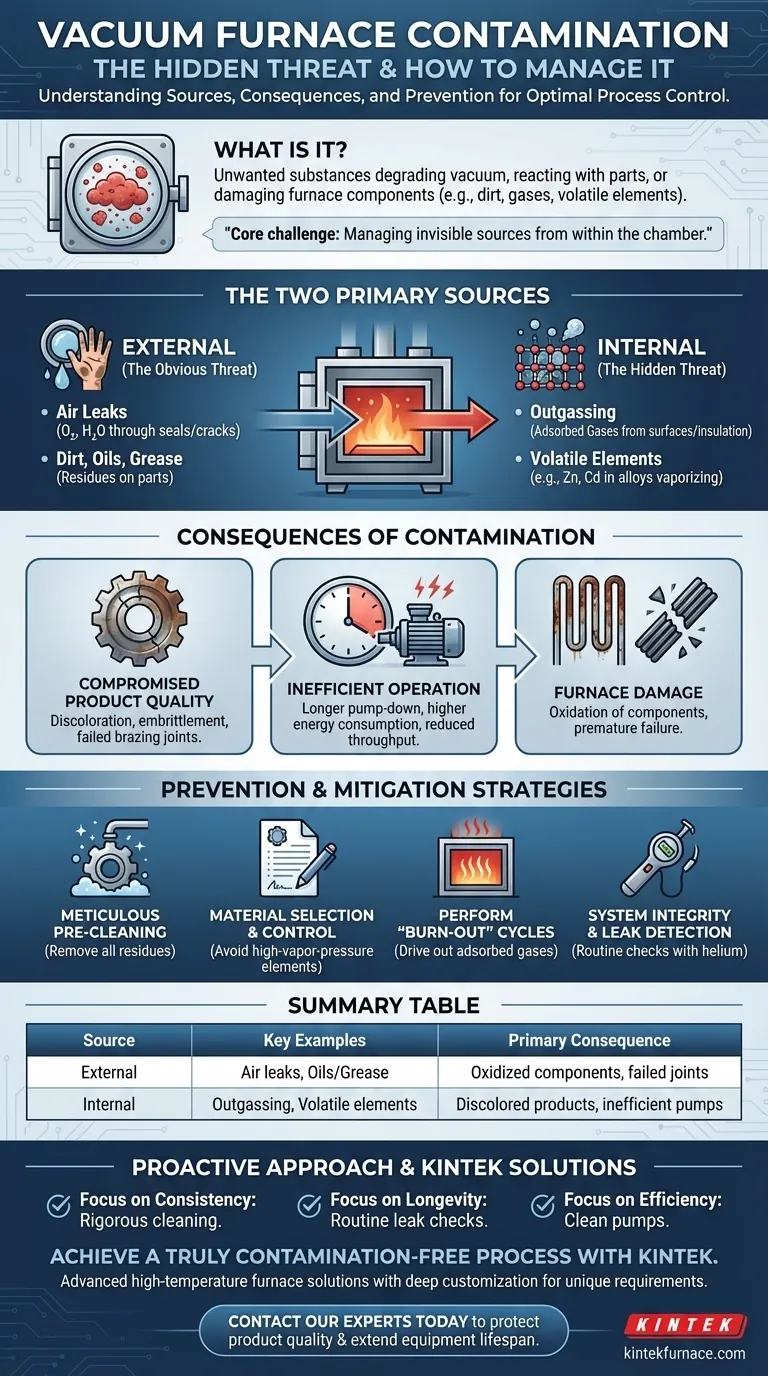

The Two Primary Sources of Contamination

Understanding contamination begins with knowing where it comes from. It falls into two main categories: substances brought in from the outside and substances that were already inside, waiting to be released.

External Contaminants: The Obvious Threat

The most straightforward source of contamination is anything introduced from outside the sealed furnace environment.

This includes air leaks through worn seals or cracks in the furnace body. Oxygen and water vapor from the air are highly reactive at high temperatures and can ruin both the product and the furnace internals.

It also includes any dirt, oils, grease, or cleaning residues left on the surface of the parts being loaded. These substances will vaporize under heat and vacuum, creating a "virtual leak" that prevents the system from reaching the target pressure.

Internal Contaminants: The Hidden Threat

More difficult to manage are the contaminants that originate from within the vacuum chamber itself.

Outgassing is the primary culprit. This is the slow release of adsorbed gases from the surfaces of the parts and the furnace's internal structures, such as the insulation and heating elements. Water vapor is a common outgassing molecule.

Certain materials also contain volatile elements that can turn into a gas at high temperatures and low pressures. For example, metals like zinc, cadmium, or lead in an alloy can vaporize and contaminate the entire system and the surfaces of other parts in the load.

Consequences of Contamination

Even minor contamination can have significant and costly effects on your process and equipment.

Compromised Product Quality

Unwanted gases can react with the metal surface, causing discoloration, embrittlement, or poor surface finish. For processes like vacuum brazing, contamination can prevent the braze alloy from wetting and flowing properly, resulting in a failed joint.

Inefficient Furnace Operation

Contaminants create a higher gas load that the vacuum pumps must constantly fight to remove. This means it takes much longer to reach the desired vacuum level, leading to longer cycle times, higher energy consumption, and reduced throughput.

Damage to Furnace Components

Oxygen from an air leak is destructive at high temperatures. It will rapidly oxidize and destroy expensive graphite components, such as heating elements and carbon felt insulation. Some metallic contaminants can also form alloys with furnace components, leading to premature failure.

Understanding Prevention and Mitigation

A clean vacuum process is not an accident; it is the result of deliberate and rigorous procedures.

The Critical Role of Pre-Cleaning

As noted in the source material, every part must be meticulously cleaned before entering the furnace. The trade-off of spending time on thorough cleaning is insignificant compared to the cost of a rejected batch or furnace damage.

Material Selection and Control

Be aware of the materials you are processing. Avoid alloys containing high-vapor-pressure elements if they are not intended for the process. This same logic applies to the furnace's internal components, which are chosen specifically for their stability under heat and vacuum.

Performing a "Burn-Out" Cycle

A common and effective maintenance procedure is to run an empty furnace cycle at a high temperature and high vacuum. This helps to drive out and pump away any adsorbed gases and low-level contaminants from the internal insulation and surfaces, restoring a clean baseline.

System Integrity and Leak Detection

Regularly inspect door seals, feedthroughs, and the furnace vessel for any signs of wear or damage. Performing a routine leak-check with a helium mass spectrometer is the professional standard for ensuring your furnace is truly sealed from the outside atmosphere.

A Proactive Approach to a Clean Process

Achieving a contamination-free process requires shifting focus from reaction to prevention. Your operational goals will determine where you place your primary effort.

- If your primary focus is process consistency: Rigorous, multi-stage part cleaning and strict control over the materials entering the furnace are non-negotiable.

- If your primary focus is equipment longevity: Prioritize routine leak detection and perform periodic high-temperature burn-out cycles to protect internal graphite and insulation.

- If your primary focus is operational efficiency: A clean furnace allows the vacuum pumps to work effectively, directly reducing cycle times and energy costs.

Ultimately, mastering contamination is fundamental to leveraging the full power of vacuum heat treatment.

Summary Table:

| Source of Contamination | Key Examples | Primary Consequence |

|---|---|---|

| External | Air leaks, Oils/Grease on parts | Oxidized furnace components, failed product joints |

| Internal | Outgassing (water vapor), Volatile elements (e.g., Zinc) | Discolored/embrittled products, inefficient pump operation |

Achieve a truly contamination-free process with KINTEK.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements and contamination control challenges.

Contact our experts today to discuss how our robust furnace solutions can protect your product quality and extend your equipment's lifespan.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing