In research and laboratory settings, vacuum experimental furnaces are primarily used to develop new materials and study chemical processes in an environment free from atmospheric contamination. They provide the precise control over both temperature and atmosphere needed for advanced work in materials science, chemistry, and physics, enabling the synthesis of materials like graphene and the study of catalytic reactions.

The core value of a vacuum furnace is not just its ability to generate high heat, but its power to create an ultra-pure, controlled environment. This allows researchers to isolate variables and ensure that experimental outcomes are a direct result of their intended process, not random atmospheric interference.

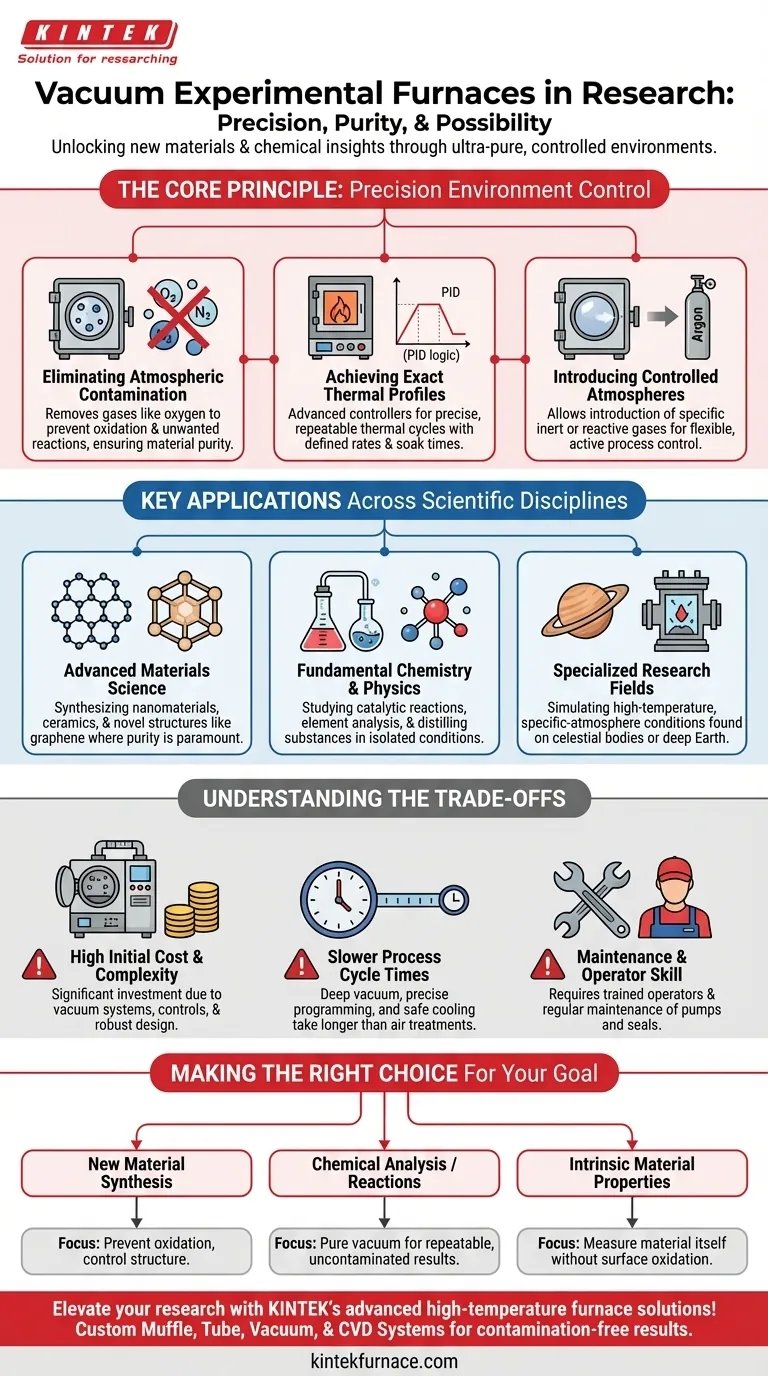

The Core Principle: Precision Environment Control

The defining capability of a vacuum furnace is its ability to manipulate the environment inside the heating chamber. This control is the foundation of its utility in a research setting.

Eliminating Atmospheric Contamination

The primary function of the vacuum is to remove atmospheric gases like oxygen and nitrogen. This is critical for preventing oxidation and other unwanted chemical reactions that would otherwise occur at high temperatures.

By creating this clean slate, researchers can ensure the material they are testing or creating retains its intrinsic properties, uncontaminated by its environment.

Achieving Exact Thermal Profiles

Laboratory furnaces feature advanced programmable controllers, often using PID (Proportional-Integral-Derivative) logic. This allows for the precise automation of complex thermal cycles.

Researchers can define exact heating rates, specific temperature "soak" times, and controlled cooling ramps. This repeatability is essential for validating scientific findings and ensuring consistent material production.

Introducing Controlled Atmospheres

A vacuum is often just the starting point. Once the chamber is evacuated, a specific gas—such as an inert gas like argon or a reactive gas—can be introduced.

This provides an active, controlled atmosphere for processes like distillation or studying specific chemical reactions, offering a level of experimental flexibility that standard furnaces cannot match.

Key Applications Across Scientific Disciplines

The combination of thermal and atmospheric control makes these furnaces a versatile tool across many fields of study.

Advanced Materials Science

This is the most common application. Vacuum furnaces are essential for synthesizing materials where purity and structure are paramount.

Examples include the preparation of ceramics, the creation of nanomaterials, and the development of novel structures like graphene. The controlled environment prevents defects and ensures the desired material phase is achieved.

Fundamental Chemistry and Physics

In chemistry and physics, these furnaces provide an ideal platform for studying processes in their purest form.

They are used for the distillation of substances, element analysis, and exploring catalytic reactions. By removing atmospheric variables, researchers can isolate the specific reactions they wish to observe.

Specialized Research Fields

The versatility of these furnaces extends to niche applications. For instance, they can be used in earth and planetary science to simulate the high-temperature, specific-atmosphere conditions found on other celestial bodies or deep within the Earth.

Understanding the Trade-offs

While powerful, vacuum furnaces are specialized equipment with inherent trade-offs compared to simpler atmospheric ovens.

High Initial Cost and Complexity

Vacuum systems, programmable controls, and robust safety features make these furnaces significantly more expensive and complex than conventional lab ovens. They represent a major capital investment.

Slower Process Cycle Times

Achieving a deep vacuum, running a precise thermal program, and safely cooling the chamber all take time. The overall cycle time for a vacuum furnace is typically much longer than for a simple heat treatment process in air.

Maintenance and Operator Skill

These are not plug-and-play devices. They require trained operators who understand vacuum technology and process parameters. Regular maintenance of pumps, seals, and control systems is critical to ensure performance and longevity.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace should be driven by the specific requirements of your experiment.

- If your primary focus is new material synthesis (e.g., alloys, advanced ceramics): The furnace's ability to prevent oxidation and control crystalline structure through precise cooling is your most critical asset.

- If your primary focus is chemical analysis or reaction studies (e.g., catalysis): The power to create a pure vacuum and then introduce specific process gases enables repeatable and uncontaminated results.

- If your primary focus is testing intrinsic material properties: Using a vacuum or inert atmosphere is non-negotiable to ensure you are measuring the material itself, not the effects of surface oxidation.

Ultimately, a vacuum furnace provides the environmental control necessary to move from approximation to precision in experimental research.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Use | Develop new materials and study chemical processes without atmospheric contamination. |

| Core Principle | Precision control of temperature and atmosphere for repeatable, uncontaminated results. |

| Main Applications | Materials science (e.g., graphene synthesis), chemistry (e.g., catalytic reactions), physics, and specialized fields. |

| Trade-offs | Higher cost, slower cycle times, and need for skilled operation and maintenance. |

Elevate your research with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering contamination-free environments and reliable performance. Contact us today to discuss how our furnaces can enhance your material synthesis and chemical studies!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion