The primary advantages of using Solid State Relays (SSRs) over traditional contactors for heating control are significantly higher precision, longer operational life, and much faster response times. Because SSRs have no moving parts, they can switch power at extremely high frequencies, enabling advanced control methods that are impossible with slower, mechanical contactors.

The core difference is not just about turning power on and off. It's about how finely you can control that power. An SSR acts like a digital dimmer switch, providing the nuanced energy delivery required for the stable, precise temperature control that sensitive processes like vacuum distillation demand.

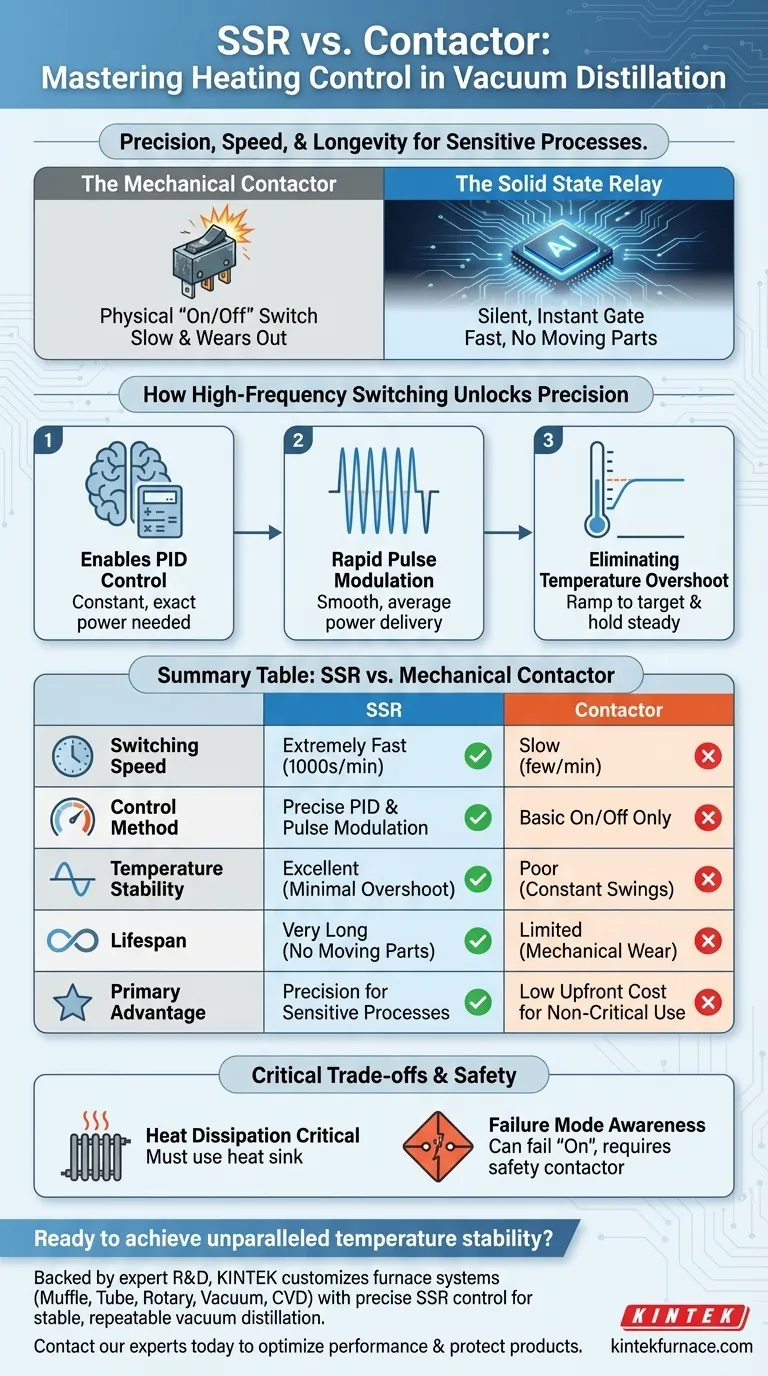

The Core Difference: Switching Mechanism and Speed

The fundamental advantage of an SSR originates from its solid-state construction, which dictates its speed and longevity.

The Mechanical Contactor: A Physical "On/Off" Switch

A traditional contactor uses an electromagnet to physically close a set of metal contacts, completing a circuit. This is a simple and robust method.

However, this mechanical action is inherently slow and creates wear and tear on the contacts with every cycle. This limits its switching frequency to only a few times per minute.

The Solid State Relay: A Silent, Instantaneous Gate

An SSR uses a semiconductor, like a thyristor or TRIAC, to switch the load. It has no moving parts.

This allows it to switch power on and off silently and almost instantaneously, thousands of times per minute, with no mechanical wear. This high-speed capability is what unlocks superior temperature control.

Why High-Frequency Switching Unlocks Precision Control

The SSR's speed isn't just about faster reaction; it enables a fundamentally different and more precise method of power regulation.

Enabling Proportional (PID) Control

Slow-switching contactors are limited to a crude "on/off" (or bang-bang) control. The heater is either at 100% power or 0% power, causing the temperature to constantly swing above and below the target setpoint.

An SSR's speed is a perfect match for PID (Proportional-Integral-Derivative) controllers, which constantly calculate the exact amount of power needed to maintain a stable temperature.

The Power of Pulse Modulation

To deliver, for example, 30% power, an SSR doesn't reduce the voltage. Instead, it uses rapid power pulse modulation.

The SSR rapidly cycles the heater on and off. By precisely controlling the ratio of "on" time to "off" time within a very short period, it delivers a smooth, average power level that holds the temperature incredibly steady.

Eliminating Temperature Overshoot

A common failure in distillation is temperature overshoot, where a slow-to-react contactor keeps the heater on too long, pushing the temperature past its setpoint and potentially damaging the product.

Because an SSR can deliver small, precise packets of energy, it can ramp up to the target temperature and hold it there with minimal to no overshoot, protecting sensitive materials.

Understanding the Trade-offs

While superior for this application, SSRs are not a universal replacement for contactors. Understanding their limitations is key to a robust system design.

Heat Dissipation is Critical

SSRs are not perfectly efficient and generate heat as a byproduct of switching high currents. They must be mounted to an appropriately sized heat sink to dissipate this thermal energy.

Inadequate heat sinking is the most common cause of SSR failure.

Sensitivity to Voltage Spikes

The semiconductor components in an SSR can be more susceptible to damage from voltage spikes on the power line than a robust mechanical contactor. Proper circuit protection is essential.

Failure Mode

A critical design consideration is that SSRs most often fail in a "shorted" or permanently on state. This can lead to a dangerous runaway heating condition.

For this reason, systems using SSRs must include an independent safety contactor or over-temperature limit controller to cut power in an emergency.

Making the Right Choice for Your Furnace

Selecting the right component requires aligning its capabilities with your primary process goal. For a vacuum distillation furnace, the choice is clear.

- If your primary focus is absolute temperature stability and product quality: The precision of an SSR combined with a PID controller is non-negotiable.

- If your primary focus is long-term reliability and reduced maintenance: The solid-state design of an SSR provides a vastly longer operational lifespan than a contactor with wearing mechanical parts.

- If your primary focus is the lowest possible upfront cost for a non-critical process: A mechanical contactor is a simpler, cheaper device, but it is not suitable for the precise control needed in vacuum distillation.

By leveraging the precise power modulation of a Solid State Relay, you ensure the stable and repeatable process conditions essential for a successful distillation.

Summary Table:

| Feature | Solid State Relay (SSR) | Mechanical Contactor |

|---|---|---|

| Switching Speed | Extremely Fast (1000s of times/min) | Slow (a few times/min) |

| Control Method | Enables Precise PID & Pulse Modulation | Limited to Basic On/Off Control |

| Temperature Stability | Excellent (Minimal Overshoot) | Poor (Constant Temperature Swings) |

| Lifespan | Very Long (No Moving Parts) | Limited (Mechanical Wear) |

| Primary Advantage | Precision Control for Sensitive Processes | Low Upfront Cost for Non-Critical Use |

Ready to achieve unparalleled temperature stability in your vacuum processes?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique needs. Our heating control solutions leverage the precision of SSRs to ensure your sensitive processes, like vacuum distillation, are stable and repeatable.

Contact our experts today to discuss how we can optimize your furnace's performance and protect your valuable products.

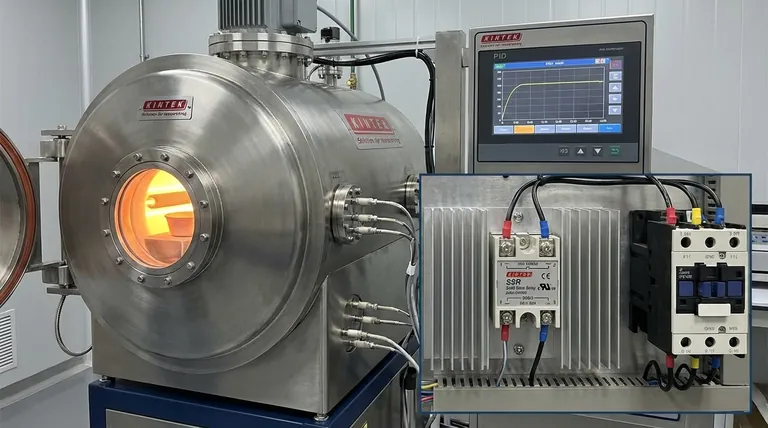

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the main technical requirements for vacuum pumps in vacuum sintering furnaces? Ensure Material Purity and Efficiency

- How does a high-vacuum pump system facilitate the synthesis of high-quality calcium-based perrhenates? Expert Synthesis

- What are the stages of a vacuum furnace pumping system and how do they function? Learn the Sequential Process for High-Vacuum Efficiency

- What is the function of vacuum systems and sealing connectors? Mastering Pure and Controlled Chemical Environments

- What design considerations are important for custom vacuum chambers? Optimize for Performance, Cost, and Application Needs