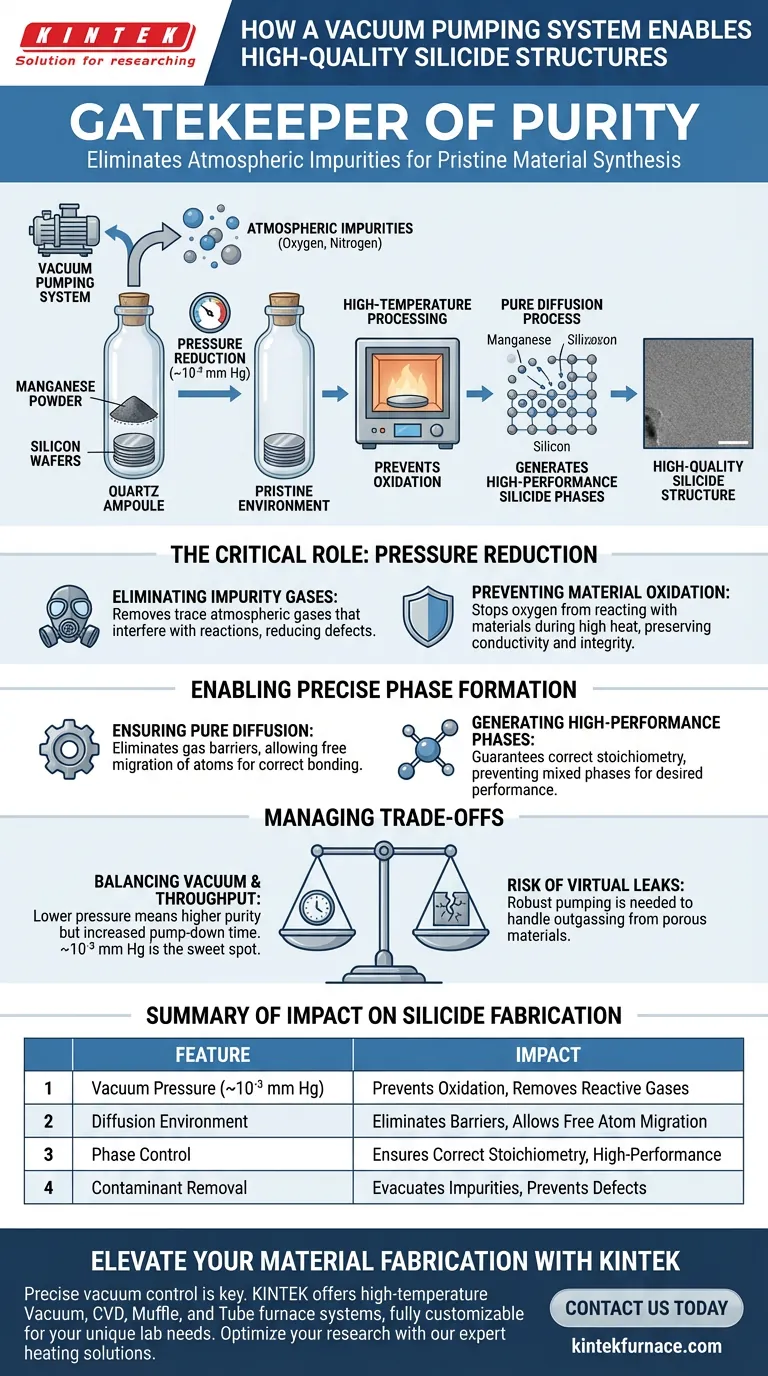

A vacuum pumping system acts as the fundamental gatekeeper of purity during silicide fabrication. By lowering the internal pressure of the reaction vessel (such as an ampoule) to approximately $10^{-3}$ mm Hg, the system actively evacuates oxygen and other atmospheric contaminants. This creates the pristine environment necessary to prevent the oxidation of sensitive materials like manganese powder and silicon wafers during high-temperature processing.

The Core Requirement High-quality silicide structures cannot form in the presence of atmospheric impurities. The vacuum system eliminates gas-phase interference, ensuring that the interaction between the metal and silicon is driven solely by diffusion rather than oxidation, which is essential for generating high-performance material phases.

The Critical Role of Pressure Reduction

To understand why the vacuum system is indispensable, one must look beyond the simple mechanics of pumping. The goal is not just "low pressure," but the specific exclusion of reactive elements.

Eliminating Impurity Gases

The primary function of the vacuum system is to remove ambient gases from the reaction ampoule. Even trace amounts of gases found in standard air can interfere with chemical reactions.

By achieving a pressure of roughly $10^{-3}$ mm Hg, the system reduces the density of these gas molecules to negligible levels. This effectively removes the variables that lead to unpredictable material defects.

Preventing Material Oxidation

Silicide fabrication requires high temperatures to trigger the reaction between metal and silicon. Unfortunately, heat also accelerates oxidation.

Without a vacuum, both the manganese powder source and the silicon wafers would react with residual oxygen. This would form unwanted oxide layers on the surface, ruining the material's conductive properties and structural integrity.

Enabling Precise Phase Formation

Once contaminants are removed, the vacuum system creates the physical conditions required for the correct chemical synthesis to occur.

Ensuring a Pure Diffusion Process

Silicide formation is fundamentally a diffusion process where metal atoms migrate into the silicon lattice.

Oxygen or nitrogen impurities can act as barriers to this migration, blocking the diffusion path. By maintaining a vacuum, the system ensures a "pure diffusion" environment where atoms can move freely and bond correctly.

Generating High-Performance Phases

The ultimate goal of this process is to create specific, high-performance phases, such as manganese silicide.

If the environment is impure, the stoichiometry of the final product changes, leading to mixed phases or poor performance. The vacuum ensures that the resulting structure is composed of the desired single-phase material necessary for high-quality device fabrication.

Understanding the Trade-offs

While vacuum systems are essential, they introduce specific challenges that must be managed to ensure success.

Balancing Vacuum Level and Throughput

Achieving pressures lower than $10^{-3}$ mm Hg yields higher purity but increases "pump-down" time significantly.

Process engineers must balance the need for extreme purity against fabrication cycle times. For many silicide processes, the $10^{-3}$ mm Hg threshold is the "sweet spot" where oxidation is prevented without excessive processing delays.

The Risk of Virtual Leaks

A high-quality pump is useless if the chamber contains materials that "outgas" (release trapped air) under vacuum.

Porous materials or trapped pockets of air inside the ampoule can act as virtual leaks, raising the pressure during the heating phase. The pumping system must be robust enough to handle this outgassing to maintain the integrity of the diffusion process.

Making the Right Choice for Your Goal

The effectiveness of your silicide fabrication depends on how strictly you control the vacuum environment relative to your specific material goals.

- If your primary focus is Phase Purity: Ensure your system can reliably hold $10^{-3}$ mm Hg or lower throughout the entire heating cycle to completely rule out oxidation.

- If your primary focus is Process Consistency: Implement rigorous leak-checking and outgassing protocols to prevent atmospheric fluctuations from altering the diffusion rate batch-to-batch.

Control the atmosphere, and you control the material quality.

Summary Table:

| Feature | Impact on Silicide Fabrication |

|---|---|

| Vacuum Pressure ($10^{-3}$ mm Hg) | Removes atmospheric oxygen and reactive gases to prevent material oxidation. |

| Diffusion Environment | Eliminates gas-phase barriers, allowing metal atoms to migrate freely into the silicon lattice. |

| Phase Control | Ensures correct stoichiometry for high-performance phases like manganese silicide. |

| Contaminant Removal | Evacuates outgassed impurities to prevent structural defects and material degradation. |

Elevate Your Material Fabrication with KINTEK

Precise vacuum control is the difference between high-performance silicides and failed batches. Backed by expert R&D and world-class manufacturing, KINTEK offers high-temperature Vacuum, CVD, Muffle, and Tube furnace systems—all fully customizable to meet your unique laboratory needs.

Our systems provide the pristine atmosphere and thermal stability required for advanced material synthesis. Contact us today to discuss your project requirements and discover how our expert heating solutions can optimize your research and production outcomes.

Visual Guide

References

- A. T. Mamadalimov, Makhmudhodzha Isaev. Study of infrared quenching in silicide-silicon-silicide structures. DOI: 10.62476/apr61.55

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What is the value of laboratory-scale melting furnaces in researching micro-alloying elements for Medium-Manganese Steel?

- What are the advantages of performing brazing in a vacuum environment? Achieve Clean, Strong Joints with Precision

- Why is reduced contamination important in vacuum sintering? Achieve Purity and Strength in Your Materials

- How does a vacuum drying oven ensure efficient encapsulation? Master Vacuum Impregnation for Phase Change Materials

- Why is a vacuum drying oven preferred for Al2O3/TiC mixed powders? Prevent Oxidation & Improve Density

- What is the significance of an automated pressure control system in a vacuum chamber? Optimize Plasma Nitriding

- How do customized vacuum furnaces meet specific process requirements? Tailor Your Heat Treatment for Maximum Efficiency

- Why is a vacuum drying oven essential during the precursor treatment of Pt/Ce(M) catalysts? Ensure High Metal Dispersion