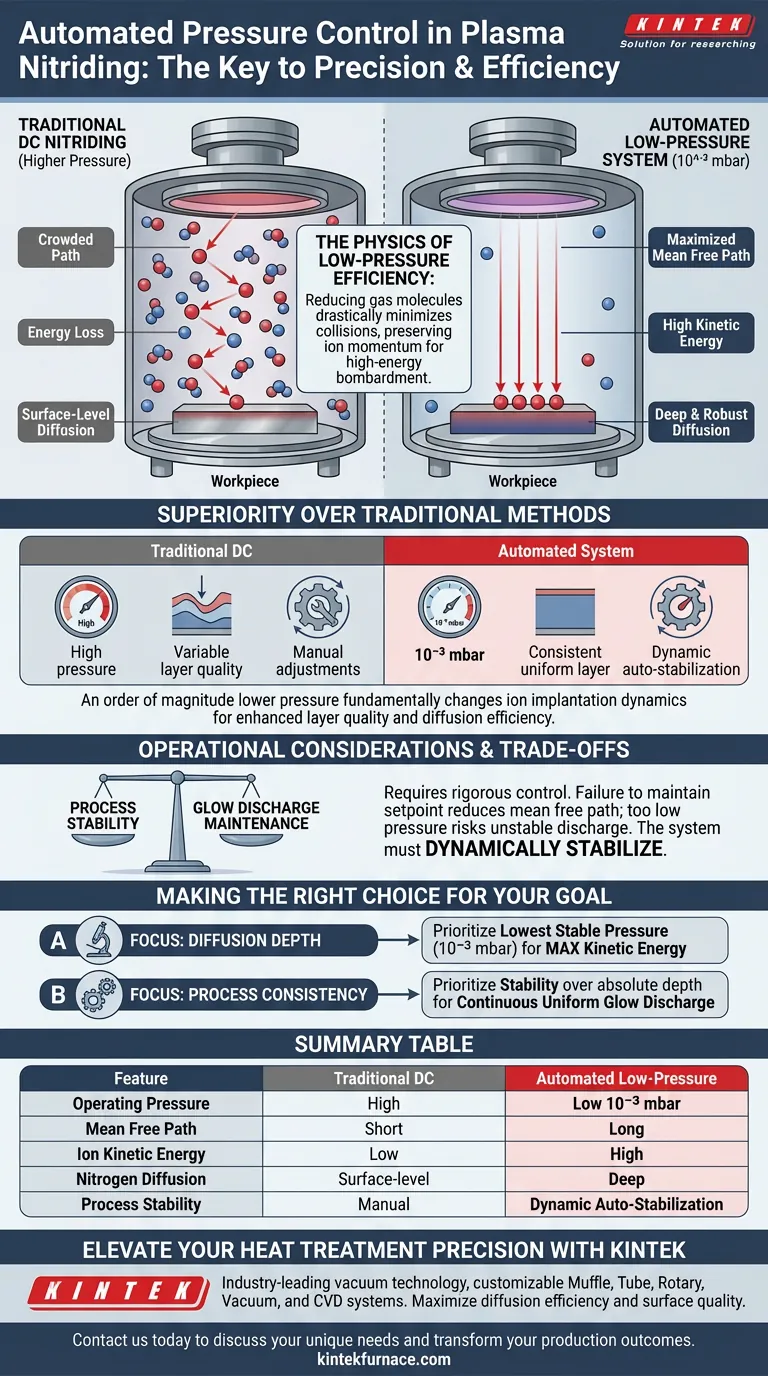

The precision of the vacuum environment is the deciding factor in the efficiency of ion delivery during plasma nitriding. An automated pressure control system enables the maintenance of extremely low pressures, specifically around 10^-3 mbar, which is an order of magnitude lower than traditional Direct Current (DC) plasma nitriding. This distinct low-pressure regime minimizes particle collisions, ensuring that ions strike the workpiece with maximum kinetic energy.

The core value of an automated pressure control system is its ability to maintain a vacuum where the mean free path is maximized. By reducing the number of gas molecules in the chamber, the system ensures ions retain energy close to the bias voltage, leading to deeper diffusion and superior surface quality.

The Physics of Low-Pressure Efficiency

Reducing Energy Loss

In a plasma nitriding chamber, ions must travel through a "sheath" to reach the workpiece.

At higher pressures, this path is crowded with gas molecules. Ions collide with these molecules, losing significant energy before they ever reach the surface.

An automated system maintains pressure at 10^-3 mbar. This low density drastically reduces the probability of these collisions, preserving the ions' momentum.

Maximizing Kinetic Energy

Because the ions encounter fewer obstacles, they are injected into the workpiece surface with energy close to the bias voltage.

This high-energy bombardment is critical. It drives nitrogen atoms effectively into the material lattice, rather than just coating the surface.

The result is a more robust interaction between the plasma and the workpiece, directly translating to improved process efficiency.

Superiority Over Traditional Methods

Beyond Traditional DC Nitriding

Traditional DC plasma nitriding typically operates at higher pressures. While functional, these systems suffer from the energy loss described above.

Automated pressure control pushes the vacuum an order of magnitude lower. This shift changes the fundamental dynamics of ion implantation.

Enhanced Layer Quality

The specific environment created by automated control facilitates a stable plasma glow discharge.

This stability ensures that the bombardment of the workpiece is uniform across the entire geometry.

Consequently, the nitrided layer formed is consistent, and the diffusion efficiency of nitrogen atoms is significantly improved compared to manual or higher-pressure systems.

Operational Considerations and Trade-offs

Process Stability Sensitivity

While lower pressure yields higher ion energy, it requires rigorous control.

If the vacuum system fails to maintain the specific setpoint (e.g., drifting above 10^-3 mbar), the mean free path decreases, and the benefits of high-energy impact are lost immediately.

Glow Discharge Maintenance

A vacuum system must be balanced to sustain the glow discharge.

If the pressure drops too low without automatic compensation, the plasma discharge can become unstable or extinguish. The automated system is not just about reaching a low number; it is about stabilizing that number dynamically to keep the plasma active.

Making the Right Choice for Your Goal

To maximize the benefits of an automated pressure control system, align your settings with your specific metallurgical objectives:

- If your primary focus is Diffusion Depth: Prioritize maintaining the lowest stable pressure (10^-3 mbar) to maximize the kinetic energy of the impacting ions.

- If your primary focus is Process Consistency: Ensure the automation logic prioritizes stability over absolute vacuum depth to maintain a continuous, uniform glow discharge.

Automated pressure control transforms the vacuum chamber from a simple container into a precision tool for maximizing ion energy.

Summary Table:

| Feature | Traditional DC Nitriding | Automated Low-Pressure System |

|---|---|---|

| Operating Pressure | High (mbar range) | Low (10^-3 mbar) |

| Mean Free Path | Short (Frequent collisions) | Long (Minimal collisions) |

| Ion Kinetic Energy | Low (Energy loss via collisions) | High (Close to bias voltage) |

| Nitrogen Diffusion | Surface-level/Variable | Deep and Robust |

| Process Stability | Manual adjustment needed | Dynamic Auto-Stabilization |

Elevate Your Heat Treatment Precision with KINTEK

Don’t let pressure fluctuations compromise your material integrity. KINTEK provides industry-leading vacuum technology backed by expert R&D and manufacturing. Our comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet the rigorous demands of plasma nitriding and high-temperature lab processes.

Ready to maximize your diffusion efficiency and surface quality? Contact us today to discuss your unique needs and see how our advanced furnace solutions can transform your production outcomes.

Visual Guide

References

- Arutiun P. Ehiasarian, P.Eh. Hovsepian. Novel high-efficiency plasma nitriding process utilizing a high power impulse magnetron sputtering discharge. DOI: 10.1116/6.0003277

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does a vacuum distillation system function in REE extraction? Master LME Separation with Precision

- What are the key steps in the working principle of a vacuum furnace? Master Precision Heat Treatment for Superior Results

- Why are refractory metals like tungsten used in vacuum furnaces? Unlock High-Temp Performance Safely

- Why is joint clearance important in vacuum brazing? Ensure Strong, Reliable Bonds

- What is a crucible furnace and what is it used for? A Guide to Clean Metal Melting

- What are the primary benefits of vacuum heat treatment technology? Achieve Superior Metallurgical Control and Quality

- Why are vacuum-melted materials preferred for medical implants? Ensure Implant Purity and Longevity

- What are the advantages of vacuum heat treatment regarding surface quality? Achieve Pristine, Oxidation-Free Surfaces